This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3945606 Dipstick is a critical component for commercial trucks, designed to monitor engine oil levels. Accurate oil level measurement is essential for maintaining engine performance and longevity, preventing damage from oil starvation or overfilling 1.

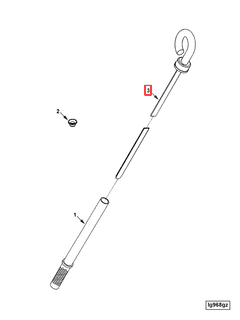

Basic Concepts of a Dipstick

A dipstick is a tool used to measure fluid levels, typically oil, within an engine’s crankcase. It features a long rod with handle and markings indicating minimum and maximum oil levels. By withdrawing and observing the oil level on the dipstick, one can ensure it is within the acceptable range 2.

Purpose of the Cummins 3945606 Dipstick

This Cummins part is engineered to measure oil levels in Cummins engines, ensuring they remain within the manufacturer’s specified range. This is vital for lubrication, cooling, and cleaning of engine components, contributing to engine efficiency and durability 3.

Key Features

The 3945606 Dipstick is known for its robust design and high-quality materials, ensuring durability and accuracy. It features clear markings for oil level indication and is designed for secure fit within the engine’s oil sump, allowing for easy insertion and removal for regular checks 4.

Benefits

Using this Cummins part offers several advantages. Its accurate measurement capabilities help maintain optimal oil levels, contributing to engine longevity and performance. The dipstick’s durable construction ensures it can withstand the harsh conditions of commercial truck operations, and its ease of use makes regular oil level checks straightforward for operators.

Installation and Usage

To install and use the 3945606 Dipstick, ensure the engine is off and cooled. Locate the dipstick tube, pull out the dipstick, wipe it clean, reinsert it fully, then check the oil level. The oil should be between the minimum and maximum marks. Add oil if necessary to reach the proper level.

Troubleshooting and Maintenance

Common issues with dipsticks include inaccurate readings due to contamination or damage. Regularly cleaning the dipstick and checking for wear can help prevent these issues. If the dipstick appears bent or damaged, it should be replaced to ensure accurate readings. Maintaining the dipstick and following the manufacturer’s guidelines for oil changes and level checks will help ensure the engine operates efficiently.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability in the commercial truck industry. The company offers a wide range of products and services designed to meet the needs of its customers, from light-duty to heavy-duty applications, across various industries.

Cummins Dipstick Part 3945606 Compatibility

The Cummins dipstick part number 3945606 is designed to fit seamlessly with a range of Cummins engines, ensuring accurate and reliable oil level checks. This dipstick is compatible with the ISC CM554 and QSC8.3 CM554 engines, making it a versatile choice for these engine models.

ISC CM554 Engines

For the ISC CM554 engines, the dipstick part 3945606 is engineered to provide precise oil level readings. Its design ensures easy access and clear visibility, facilitating routine maintenance checks.

QSC8.3 CM554 Engines

Similarly, the dipstick part 3945606 is tailored to fit the QSC8.3 CM554 engines. It is crafted to meet the specific requirements of these engines, ensuring that users can perform oil level checks with confidence and accuracy.

Installation and Usage

When installing the dipstick part 3945606, it is crucial to follow the manufacturer’s guidelines to ensure proper fit and function. This dipstick is designed to integrate smoothly with the specified engines, providing a reliable tool for maintenance purposes.

Role of Part 3945606 Dipstick in Engine Systems

This part is an integral component in the operation and maintenance of engine systems, specifically interacting with the oil level and gauge components.

When inserted into the engine, the dipstick serves as a direct interface for measuring the oil level within the crankcase. This measurement is essential for ensuring that the engine maintains optimal lubrication, which is fundamental for the longevity and efficiency of the engine’s moving parts.

Furthermore, the dipstick is designed to work in conjunction with the oil level gauge, which may be a simple mechanical indicator or a more complex electronic sensor. The gauge relies on the information provided by the dipstick to display the current oil level to the operator or the engine management system. This interaction allows for real-time monitoring and ensures that the oil level remains within the specified range, preventing both overfilling and underfilling scenarios that could lead to engine damage.

Conclusion

The Cummins 3945606 Dipstick plays a significant role in the engine’s lubrication system by providing accurate oil level readings that are vital for the proper functioning and maintenance of the engine. Regular use and maintenance of this part ensure that the engine operates efficiently and remains in optimal condition.

-

Heywood, J. (2019). Internal Combustion Engine Fundamentals. McGraw-Hill Education.

↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Calder, N. (2007). Diesel Engine Care and Repair. The McGraw-Hill Companies.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.