This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

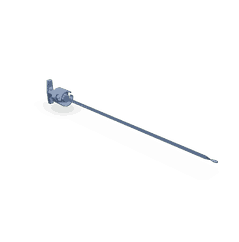

The Cummins 3965324 dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role is integral to the operation and maintenance of these vehicles, as it allows for the regular assessment of oil levels, which is vital for maintaining engine health. Proper oil level monitoring ensures that the engine remains adequately lubricated, which in turn helps to prevent wear and tear on engine components, maintain optimal performance, and extend the engine’s operational life 4.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool in the engine lubrication system. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump, and when withdrawn, the oil level can be read from the markings on the dipstick. Dipsticks are typically made from materials that can withstand high temperatures and resist corrosion, ensuring durability and accuracy in readings 1. The structure of a dipstick includes a tapered tip that fits snugly into the oil sump and a calibrated section with markings to indicate the oil level.

Purpose of the Cummins 3965324 Dipstick

The Cummins 3965324 dipstick serves a specific role in the operation of commercial trucks by facilitating the monitoring of oil levels within the engine. This monitoring is crucial for ensuring that the engine components receive adequate lubrication. Proper lubrication reduces friction between moving parts, helps in cooling the engine by carrying away heat, and assists in cleaning the engine by transporting contaminants to the oil filter 2. The dipstick allows for quick and easy checks of the oil level, enabling timely top-ups or changes as needed to maintain engine efficiency and longevity.

Key Features

The Cummins 3965324 dipstick is characterized by several key features that enhance its functionality and durability. It is designed with a robust construction to withstand the harsh conditions within a commercial truck engine. The dipstick is made from high-quality materials that resist corrosion and high temperatures, ensuring accurate and reliable readings over time. Its design includes clear, easy-to-read markings for oil level indication, and the tapered tip ensures a secure fit within the engine’s oil sump. These features contribute to the dipstick’s effectiveness in maintaining engine health through consistent and accurate oil level monitoring 3.

Benefits of Using the Cummins 3965324 Dipstick

Utilizing the Cummins 3965324 dipstick offers several benefits that contribute to improved engine performance and reliability. By ensuring that oil levels are consistently monitored and maintained, the dipstick helps in reducing engine wear, enhancing fuel efficiency, and prolonging engine life. Proper lubrication facilitated by accurate oil level readings leads to smoother engine operation, reduced maintenance costs, and increased overall reliability of the vehicle. These benefits are achieved through the dipstick’s role in facilitating easy and accurate oil level checks, which are fundamental to maintaining the engine in optimal condition 4.

Troubleshooting and Maintenance

To ensure the Cummins 3965324 dipstick remains effective, it is important to address common issues such as inaccurate readings or physical damage. Inaccurate readings may be due to a bent dipstick, incorrect insertion, or oil contamination, and can often be resolved by cleaning the dipstick or ensuring it is properly inserted. Physical damage to the dipstick, such as cracks or bends, may require replacement. Regular maintenance, including cleaning the dipstick after each use and inspecting it for signs of wear or damage, is recommended to ensure it remains in optimal condition. This proactive approach to maintenance helps in maintaining the accuracy and reliability of oil level readings 1.

Installation and Usage

Proper installation and usage of the Cummins 3965324 dipstick are crucial for accurate oil level monitoring. To install, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, usually found on the side of the engine, and remove the dipstick by pulling it straight out. To check the oil level, wipe the dipstick clean, reinsert it fully into the tube, and then remove it again to read the oil level against the markings. It is important to check the oil level with the vehicle on a level surface to ensure accuracy. Regular checks, especially before long journeys, help in maintaining optimal engine performance and longevity 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to excellence is evident in its engine components, such as the 3965324 dipstick, which are designed with precision and durability in mind. Cummins’ dedication to advancing technology and improving efficiency in power solutions underscores its position as a leader in the industry 3.

Cummins Engine Dipstick Compatibility

The Cummins part number 3965324, which is a Dipstick, is designed to be compatible with a range of Cummins engines. This dipstick is essential for checking the oil level in the engine, ensuring that it remains within the optimal range for efficient operation and longevity.

B4.5 Engines

The B4.5 engine is a part of the Cummins B Series, known for its reliability and performance in various applications. The dipstick 3965324 fits seamlessly into the B4.5 engine, providing an accurate reading of the oil level. This compatibility ensures that users can maintain their engine’s health with ease.

QSB3.9 30 and CM550 Engines

The QSB3.9 30 and CM550 engines are both part of the Cummins QSB Series, which is designed for heavy-duty applications. These engines benefit from the use of the dipstick 3965324, as it allows for precise oil level monitoring. This is crucial for maintaining the engine’s performance and preventing potential damage due to low oil levels.

By using the dipstick 3965324, owners of these engines can ensure that their vehicles are running smoothly and efficiently. The dipstick’s design and fit are tailored to provide reliable and accurate readings, making it an indispensable tool for engine maintenance.

Role of Part 3965324 Dipstick in Engine Systems

The part 3965324 dipstick is an essential component in the engine system, facilitating the accurate measurement and monitoring of the oil level. This component interfaces directly with the oil pan, allowing for the extraction of a small amount of oil which is then gauged to determine the current oil level within the system.

When the dipstick is inserted into the oil pan and subsequently withdrawn, the oil adhering to it provides a visual and tactile indication of the oil level. This information is vital for maintaining the engine’s lubrication system, ensuring that there is sufficient oil to reduce friction between moving parts, cool the engine, and carry away contaminants.

The dipstick also plays a role in conjunction with the oil level gauge, which may be a simple visual marking on the dipstick itself or a more complex electronic sensor system. The gauge allows for a precise reading of the oil level, informing the operator or automated system of the need for oil top-ups or changes.

In summary, the part 3965324 dipstick is integral to the maintenance of the engine’s lubrication system. It works in tandem with the oil level gauge to provide accurate readings, ensuring the engine operates within safe parameters and prolonging the lifespan of the engine components 4.

Conclusion

The Cummins 3965324 dipstick is a vital component for maintaining the health and efficiency of commercial truck engines. By facilitating accurate oil level monitoring, this part ensures that engines remain adequately lubricated, reducing wear and tear, enhancing performance, and extending operational life. Its robust design, compatibility with various Cummins engines, and ease of use make it an indispensable tool for engine maintenance and reliability.

-

Electrical Systems and Mechatronics, Second Edition, Michael Hilgers, Springer Vieweg, 2023

↩ ↩ -

Introduction to Internal Combustion Engines, Fourth Edition, Richard Stone, Macmillan, 2012

↩ ↩ -

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ -

Road and Off-Road Vehicle Dynamics, Moustafa ElGindy and Zeinab ElSayegh, Springer Nature, 2023

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.