This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3973011 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the monitoring of engine oil levels, ensuring that the engine operates within optimal parameters. This part is significant in the context of heavy-duty truck maintenance as it provides a straightforward yet effective means of assessing the engine’s lubrication system, thereby contributing to the overall reliability and performance of the vehicle.

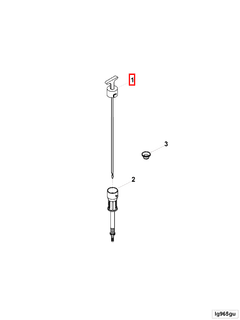

Basic Concepts of a Dipstick

A dipstick is a thin, graduated metal or plastic rod used to measure the level of fluid within an engine. It functions by being inserted into a tube connected to the sump or reservoir of the fluid being measured. Once inserted and then withdrawn, the fluid level can be read from the markings on the dipstick. In the context of an engine, the dipstick plays a role in monitoring fluid levels by providing a visual and tactile indication of whether the fluid is within the appropriate range 1.

Purpose of the Cummins 3973011 Dipstick

This Cummins part is specifically engineered to play a role in the operation and maintenance of heavy-duty trucks by allowing for the accurate measurement of engine oil levels. This is vital for ensuring that the engine remains properly lubricated, which in turn helps to prevent excessive wear, overheating, and potential damage to engine components.

Key Features

The Cummins 3973011 Dipstick incorporates several design elements and materials that enhance its functionality. It is constructed from high-quality steel, which provides durability and resistance to corrosion. The dipstick features clear, easy-to-read markings for precise fluid level indication. Additionally, it is designed to fit securely within the engine’s oil filler tube, ensuring accurate readings and preventing fluid leaks.

Benefits

Using this part offers several advantages. Its high-quality construction ensures durability and longevity, even under the demanding conditions typical of heavy-duty truck operations. The clear markings on the dipstick contribute to improved accuracy in fluid level readings, facilitating more effective maintenance practices. Furthermore, its design allows for ease of use, making it simple for operators to check oil levels quickly and efficiently.

Installation Process

Installing the Cummins 3973011 Dipstick involves several steps to ensure proper fitting and function. First, ensure the engine is turned off and has cooled down to avoid burns from hot engine components. Locate the oil filler cap on the engine and remove it. Insert the dipstick into the tube until it reaches the bottom, then withdraw it slowly. Check the fluid level against the markings on the dipstick. For installation, simply insert the dipstick fully into the tube and secure the oil filler cap. Tools required for this process are minimal, typically just a socket wrench for removing the oil filler cap.

Troubleshooting Common Issues

Common problems associated with dipsticks can include inaccurate readings, difficulty in insertion or removal, and corrosion. Inaccurate readings may be due to a bent dipstick or incorrect insertion. Ensuring the dipstick is straight and fully inserted can resolve this issue. Difficulty in insertion or removal might indicate a buildup of sludge or debris, which can be cleaned with a solvent. Corrosion can be mitigated by using a dipstick made from corrosion-resistant materials, such as the high-quality steel used in the Cummins 3973011 Dipstick 2.

Maintenance Tips

To ensure the longevity and optimal performance of the Cummins 3973011 Dipstick, regular maintenance practices are recommended. These include cleaning the dipstick regularly to remove any buildup of sludge or debris, checking for signs of wear or corrosion, and ensuring it is properly seated in the oil filler tube. Additionally, operators should verify that the oil level is consistently within the recommended range to prevent engine damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. Founded in 1919, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industry. The company’s commitment to excellence is reflected in its products, including the Cummins 3973011 Dipstick, which is designed to meet the rigorous demands of heavy-duty applications.

Cummins Dipstick 3973011 Compatibility with ISL Engines

The Cummins dipstick part number 3973011 is designed to be compatible with several ISL engine models. This dipstick is a crucial component for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently. Here is a detailed look at how this part fits with the specified ISL engines:

ISL CM2150 and ISL9 CM2150 SN

The dipstick 3973011 is specifically engineered to fit the ISL CM2150 and ISL9 CM2150 SN engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The dipstick is designed to provide an accurate reading of the oil level, which is essential for maintaining the engine’s health and preventing potential damage from low oil levels.

ISL CM554 and ISL9 CM2250

Similarly, the dipstick 3973011 is also compatible with the ISL CM554 and ISL9 CM2250 engines. These engines, like their counterparts, require precise oil level monitoring to ensure optimal performance. The dipstick’s design allows for easy insertion and removal, providing a clear view of the oil level for the operator.

Grouping of Compatible Engines

The compatibility of the dipstick 3973011 with the ISL CM2150 and ISL9 CM2150 SN engines, as well as the ISL CM554 and ISL9 CM2250 engines, indicates that Cummins has standardized certain components across different engine models. This standardization ensures that maintenance and repair processes are streamlined, making it easier for technicians to work on multiple engine types with a common set of tools and parts.

By using the dipstick 3973011, operators and technicians can ensure that they are accurately monitoring the oil levels in these engines, which is critical for maintaining engine performance and longevity.

Role of Part 3973011 Dipstick in Engine Systems

The part 3973011 dipstick is an essential component in the maintenance and monitoring of engine systems. It works in conjunction with several key components to ensure the engine operates efficiently and safely.

Interaction with the Oil Level

The primary function of the 3973011 dipstick is to provide a means of checking the oil level within the engine. When inserted into the oil filler tube, the dipstick allows mechanics and engineers to visually assess the amount of oil present. This is vital for maintaining the correct oil level, which is necessary for lubricating moving parts, cooling the engine, and cleaning internal components.

Integration with the Gauge

In some engine systems, the dipstick may be paired with an oil level gauge or sensor. This setup enhances the accuracy of oil level readings. The gauge can provide a more precise measurement, often converting the visual reading from the dipstick into a digital or analog display. This integration is particularly useful in high-performance engines where maintaining optimal oil levels is paramount.

Ensuring Engine Health

By regularly using the 3973011 dipstick to check the oil level, engineers and mechanics can prevent issues such as oil starvation, which can lead to increased friction, overheating, and ultimately, engine failure. Consistent monitoring allows for timely top-ups or changes, ensuring the engine remains in peak condition.

Facilitating Maintenance Procedures

During routine maintenance, the dipstick serves as a quick diagnostic tool. It allows for the inspection of oil quality, detecting contaminants or degradation that might indicate the need for an oil change. This proactive approach helps in identifying potential issues before they escalate into more significant problems.

Supporting Diagnostic Processes

In diagnostic scenarios, the dipstick can offer clues about the engine’s internal health. Unusual readings or oil conditions (such as foamy or milky oil) can signal issues like coolant leaks or blown head gaskets. This makes the dipstick a valuable tool in the early detection of engine problems.

The 3973011 dipstick, through its interaction with the oil level and potential integration with gauges, plays a significant role in the upkeep and diagnostic processes of engine systems. Its use ensures that engines operate within safe parameters, contributing to their longevity and performance 3.

Conclusion

The Cummins 3973011 Dipstick is a critical component in the maintenance and monitoring of heavy-duty truck engines. Its design and functionality ensure accurate oil level readings, contributing to engine health and performance. Regular use and maintenance of this part are essential for preventing engine damage and ensuring optimal operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.