This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

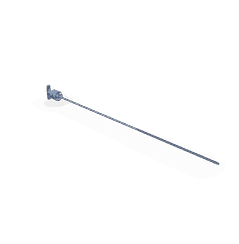

The Cummins 3973950 Dipstick is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the monitoring of engine oil levels, which is a fundamental aspect of routine maintenance. Ensuring the correct oil level is maintained contributes to the efficient operation and longevity of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in engines to measure the level of fluid, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The rod is inserted into a tube connected to the oil pan of the engine. Once inserted and then removed, the oil level can be read from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the recommended range, facilitating timely top-ups or changes as needed 2.

Purpose of the Cummins 3973950 Dipstick

The Cummins 3973950 Dipstick plays a specific role in the operation and maintenance of commercial trucks by enabling the accurate measurement of engine oil levels. Regular checks using this dipstick help ensure that the engine operates with the correct amount of lubrication, which is crucial for reducing wear and maintaining performance. It is particularly designed to fit and function optimally with Cummins engines, ensuring precise measurements 3.

Key Features

The Cummins 3973950 Dipstick is characterized by several key features that enhance its functionality. It is constructed from durable materials to withstand the harsh conditions within a commercial truck engine. The design includes clear, easy-to-read markings for accurate oil level assessment. Additionally, the dipstick is engineered to fit securely within the engine, preventing oil leaks and ensuring reliable measurements.

Benefits

Using the Cummins 3973950 Dipstick offers several advantages. Its design ensures accurate fluid level measurements, which is vital for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to wear and corrosion. Furthermore, the ease of use associated with this dipstick simplifies the maintenance process for commercial truck operators.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings due to wear or contamination. Regular inspection and cleaning of the dipstick can help maintain its accuracy. If the dipstick shows signs of damage or if readings become inconsistent, replacement is recommended to ensure reliable oil level measurements. Proper storage and handling of the dipstick when not in use also contribute to its longevity.

Installation and Usage

Proper installation and usage of the Cummins 3973950 Dipstick involve a few straightforward steps. First, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, typically found near the engine’s oil pan. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level against the markings. For safety, always handle the dipstick carefully and avoid contact with hot engine components.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is renowned for its commitment to quality, innovation, and customer satisfaction, providing reliable and efficient components that meet the demanding requirements of commercial transportation.

Cummins Part 3973950 Dipstick Compatibility

The Cummins part 3973950, a Dipstick, is designed to fit seamlessly with several of the QSC and QSL series engines. This dipstick is crucial for checking the oil level in the engine, ensuring that the engine operates smoothly and efficiently.

QSC8.3 CM850 (CM2850) and QSC9 CM2250/QSL9 CM2250

The dipstick is compatible with the QSC8.3 CM850 (CM2850) engine. This engine is known for its robust performance and reliability, making it a popular choice in various applications. The dipstick ensures that the oil level is maintained at optimal levels, preventing engine damage due to insufficient lubrication.

Similarly, the QSC9 CM2250 and QSL9 CM2250 engines also benefit from the use of the Cummins part 3973950 dipstick. These engines are engineered for high performance and durability, often used in demanding environments. The dipstick’s precise fit and design allow for accurate oil level readings, ensuring that these engines run smoothly and efficiently.

By using the Cummins part 3973950 dipstick, engine operators can easily monitor and maintain the oil levels in these engines, contributing to their longevity and performance.

Role of Part 3973950 Dipstick in Engine Systems

The part 3973950 dipstick is an essential component in the maintenance and operation of engine systems. It works in conjunction with several key components to ensure the engine operates efficiently and remains in optimal condition.

Interaction with the Oil Level

The primary function of the dipstick is to provide a means of checking the oil level within the engine. When inserted into the oil filler tube, the dipstick allows mechanics and engineers to visually assess the amount of oil present. This is vital for maintaining the correct oil level, which is necessary for lubricating moving parts, cooling the engine, and reducing wear and tear.

Connection to the Gauge

While the dipstick itself does not directly interface with a gauge, the information obtained from the dipstick is often used in conjunction with oil pressure gauges and other monitoring systems. The oil level reading from the dipstick can inform adjustments or indicate potential issues that might be reflected in the gauge readings. For instance, low oil levels can lead to decreased oil pressure, which would be visible on an oil pressure gauge.

Ensuring Engine Health

Regular use of the dipstick to check oil levels helps in the early detection of oil leaks or excessive consumption, which can be indicative of more significant engine issues. By maintaining the appropriate oil level, the dipstick indirectly supports the engine’s overall health and performance. This preventive maintenance step is integral to avoiding more complex and costly repairs down the line.

Facilitating Oil Changes

During oil changes, the dipstick is used to ensure that the correct amount of new oil is added to the engine. After draining the old oil, the dipstick helps in verifying that the new oil level is within the manufacturer’s specified range, ensuring the engine is properly lubricated.

Supporting Diagnostic Processes

In diagnostic scenarios, the dipstick can provide valuable insights. The condition of the oil (e.g., presence of metal filings, sludge) observed on the dipstick can indicate internal engine wear or contamination, guiding further investigative actions.

Conclusion

In summary, the Cummins 3973950 Dipstick plays a significant role in the routine maintenance and diagnostic processes of engine systems. Its accurate measurements and durable design contribute to the efficient operation and longevity of commercial truck engines. Regular use and proper maintenance of this part are essential for ensuring optimal engine performance and preventing costly repairs.

-

Tigran Parikyan Ed, Advances in Engine and Powertrain Research and Technology, Springer Nature, 2022.

↩ -

Julian Happian-Smith, An Introduction to Modern Vehicle Design, Butterworth-Heinemann, 2002.

↩ -

Sean Bennett, Ian Andrew Norman, Heavy Duty Truck Systems Fifth Edition, Delmar Cengage Learning, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.