This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

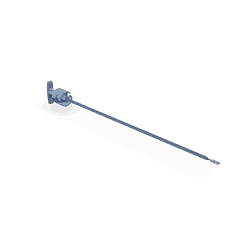

The Cummins 4007628 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the measurement of engine oil levels, ensuring that the engine remains properly lubricated. This part is significant in the context of heavy-duty truck maintenance as it provides a straightforward yet effective means of monitoring oil levels, which is vital for the longevity and performance of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a thin, graduated metal or plastic rod used to measure the level of fluid in an engine. It operates by being inserted into a compartment within the engine that holds the fluid—in this case, engine oil. Once inserted and then withdrawn, the dipstick displays the fluid level by means of markings along its length. The general principle behind its operation involves simple visual inspection to determine if the fluid level is within the acceptable range 2.

Purpose of the Cummins 4007628 Dipstick

The Cummins 4007628 Dipstick plays a role in the operation of a truck by allowing for the precise measurement of oil levels within the engine. Proper lubrication is necessary for the engine’s moving parts to function smoothly and efficiently. By providing an accurate reading of the oil level, this Cummins part helps ensure that the engine maintains optimal lubrication, which is crucial for its performance and durability 3.

Key Features

The Cummins 4007628 Dipstick is characterized by its robust design and the materials used in its construction. Typically made from high-quality steel, it is resistant to corrosion and wear, ensuring durability in the demanding environment of a heavy-duty truck engine. Its design may include a handle for easy gripping and a tapered tip for precise insertion into the dipstick tube. Additionally, clear and durable markings along the length of the dipstick facilitate accurate readings 4.

Benefits of Using the Cummins 4007628 Dipstick

Utilizing the Cummins 4007628 Dipstick offers several advantages. Its design ensures accuracy in oil level measurement, which is vital for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to the harsh conditions within an engine compartment. Furthermore, its ease of use, with a simple insertion and withdrawal process, allows for quick and efficient oil level checks during routine maintenance 5.

Installation and Usage

To properly install and use the Cummins 4007628 Dipstick, follow these steps: First, ensure the truck is on a level surface and the engine is off to obtain an accurate reading. Locate the dipstick tube, usually found near the engine’s top. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then withdraw it again to check the oil level. The oil should be between the minimum and maximum marks. For the most accurate reading, check the level a few times, ensuring the dipstick is wiped clean between checks 6.

Troubleshooting Common Issues

Common problems with dipsticks include inaccurate readings or physical damage. Inaccurate readings may result from an improperly seated dipstick or contamination on the dipstick’s surface. Ensuring the dipstick is fully inserted and wiped clean before taking a reading can resolve this issue. Physical damage, such as bends or corrosion, may require replacement of the dipstick to ensure accurate measurements and prevent potential engine damage 7.

Maintenance Tips

To maintain the Cummins 4007628 Dipstick and ensure its longevity and reliable performance, regular cleaning and inspection are recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Periodically inspect the dipstick for signs of wear, corrosion, or damage. If any issues are detected, consider replacing the dipstick to maintain the accuracy of oil level readings and protect the engine’s health 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the production of diesel engines and related components. Their commitment to excellence and customer satisfaction has made them a preferred choice for heavy-duty applications, including trucks and industrial equipment 9.

Role of Part 4007628 Dipstick in Engine Systems

The part 4007628 Dipstick is an essential component in the maintenance and monitoring of engine systems. Its primary function is to provide a means for checking the oil level within the engine. This is achieved through its integration with the Oil Level Gauge system.

Integration with Oil Level Gauge

When the dipstick is inserted into its designated location within the engine, it comes into contact with the engine oil. The oil adheres to the dipstick, allowing for a precise measurement of the oil level. The markings on the dipstick correspond to specific oil levels, which are then read by the Oil Level Gauge. This gauge provides a visual or digital readout, enabling engineers and mechanics to assess whether the oil level is within the optimal range 10.

Location and Accessibility

The dipstick is typically located in an easily accessible area of the engine, often near the top, allowing for convenient checking of the oil level without the need for extensive disassembly. This strategic placement ensures that regular maintenance checks can be performed efficiently, contributing to the overall reliability and performance of the engine system 11.

Importance in Maintenance Routines

Regular use of the dipstick in conjunction with the oil level gauge is a fundamental part of engine maintenance routines. It allows for the early detection of oil leaks, consumption, or contamination, which can prevent more severe engine damage. Additionally, maintaining the correct oil level is vital for lubrication, cooling, and cleaning within the engine, directly impacting its longevity and efficiency 12.

Conclusion

The Cummins 4007628 Dipstick is a vital component in the maintenance of heavy-duty truck engines. Its design and functionality ensure accurate oil level measurements, contributing to the engine’s performance, durability, and overall health. Regular maintenance and proper use of this part are essential for the longevity and efficiency of the engine system.

-

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Garrett, T.K., Newton, K., & Steeds, W. (2001). The Motor Vehicle. Reed Educational and Professional Publishing Ltd.

↩ -

Trzesniowski, M. (2023). The Complete Vehicle. Springer Nature.

↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.