This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

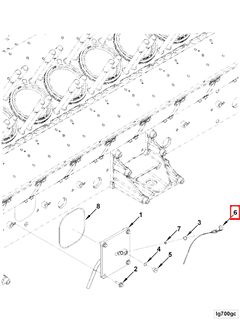

The Cummins 4013242 Dipstick is a specialized component designed for use in commercial trucks. Its purpose is to facilitate the measurement of oil levels within the engine, ensuring that the engine operates within optimal parameters. This Cummins part is significant in the maintenance routine of commercial trucks, as regular oil level checks are vital for engine health and performance 1.

Basic Concepts of a Dipstick

A dipstick is a thin, tapered metal or plastic rod used to measure the level of fluid in a container. In the context of an engine, it is inserted into the oil reservoir and then withdrawn to check the oil level. The dipstick typically has markings that indicate the safe operating range for the oil level. It operates by being fully inserted into the oil fill tube until it reaches the bottom, then pulled out to observe where the oil level lies in relation to the markings 2.

Purpose of the Cummins 4013242 Dipstick

This Cummins part plays a role in the operation and maintenance of a truck by allowing technicians to check the oil levels accurately. Proper oil levels are necessary for lubricating engine components, reducing friction, and preventing wear. Regular checks with this dipstick help ensure that the engine maintains optimal performance and longevity 3.

Key Features

The Cummins 4013242 Dipstick is characterized by its robust design and material selection, which enhance its durability and accuracy. It is crafted from high-quality materials that resist corrosion and wear, ensuring reliable performance over time. The dipstick’s design includes precise markings for easy reading and a tapered shape that fits securely into the oil fill tube.

Benefits

Using the Cummins 4013242 Dipstick offers several advantages. It contributes to improved engine performance by enabling regular and accurate oil level checks, which are part of routine maintenance. Consistent maintenance with this dipstick can lead to prolonged engine life, as it helps prevent issues that arise from low or contaminated oil levels.

Installation and Usage

To install and use the Cummins 4013242 Dipstick, follow these steps: First, ensure the truck is on a level surface and the engine is off. Locate the oil fill tube and remove the existing dipstick. Insert the Cummins 4013242 Dipstick fully into the tube, then withdraw it to check the oil level against the markings. Wipe the dipstick clean, reinsert it fully, and then remove it again for a final reading. Safety precautions include wearing protective gloves and ensuring the area is well-ventilated.

Troubleshooting and Maintenance

Common issues with dipsticks include inaccurate readings or physical damage. To address these, inspect the dipstick regularly for signs of wear or bending. If inaccurate readings are suspected, clean the dipstick and ensure it is fully seated in the oil fill tube during measurement. Regular maintenance of the dipstick involves keeping it clean and checking for any damage that could affect its accuracy.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the commercial truck industry. The company is committed to quality and innovation, providing solutions that enhance the performance and reliability of commercial vehicles.

Cummins Engine Dipstick Compatibility

The Cummins part number 4013242, which is a Dipstick, is designed to fit a variety of Cummins engines. This dipstick is an essential tool for checking the oil level in these engines, ensuring that they operate smoothly and efficiently.

QSV81G and QSV91G

The dipstick 4013242 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The dipstick is engineered to fit snugly into the designated oil check port of these engines, providing an accurate reading of the oil level.

QSV91-G4 CM558/CM700 V102

For the QSV91-G4 CM558/CM700 V102 engine, the dipstick 4013242 is also a perfect match. This engine variant is part of Cummins’ advanced lineup, offering enhanced features and performance. The dipstick ensures that operators can easily and accurately monitor the oil levels, which is crucial for maintaining the engine’s optimal condition.

QSW/QSV82 and QSW73

The dipstick 4013242 is also suitable for the QSW/QSV82 and QSW73 engines. These engines are designed for versatility and efficiency, often used in a range of applications from construction to agriculture. The dipstick’s design allows for easy insertion and removal, providing clear visibility of the oil level for quick and effective maintenance.

Role of Part 4013242 Dipstick in Engine Systems

The part 4013242 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. Its primary function is to provide a precise reading of the oil level, which is vital for the maintenance and performance of the engine.

Interaction with the Oil Level Gauge

The dipstick interfaces directly with the oil level gauge, allowing for an accurate assessment of the oil quantity within the engine. When the dipstick is inserted into the engine’s oil reservoir and then withdrawn, the oil adhering to it provides a visual and tactile indication of the oil level. This information is then interpreted by the oil level gauge, which may be a simple mechanical indicator or a more advanced electronic sensor. The gauge translates the dipstick reading into a format that is easily understandable by the operator, ensuring that the oil level remains within the optimal range for engine operation.

Importance in Determining Oil Level Location

Accurately determining the oil level location is another significant aspect of the dipstick’s role. The dipstick is designed to reach the lowest point of the oil reservoir, ensuring that the reading reflects the actual oil volume. This is particularly important in engines where the oil reservoir may have irregular shapes or multiple compartments. The dipstick’s design allows it to navigate these complexities, providing a consistent and reliable measurement regardless of the reservoir’s geometry.

Ensuring Engine Health through Consistent Monitoring

Consistent monitoring of the oil level using the dipstick is fundamental to maintaining engine health. Proper oil levels are necessary for adequate lubrication of moving parts, cooling of the engine, and sealing of combustion chambers. The dipstick facilitates this by offering a straightforward method for regular checks, allowing for timely top-ups or changes as needed. This proactive approach helps prevent issues such as metal-to-metal contact, overheating, and seal failures, all of which can lead to significant engine damage.

Conclusion

In summary, the Cummins 4013242 Dipstick plays a pivotal role in the engine system by ensuring accurate oil level measurements, facilitating the function of the oil level gauge, and contributing to the overall maintenance and longevity of the engine. Regular use of this part is essential for maintaining optimal engine performance and preventing potential damage.

-

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition, Springer Vieweg, 2007.

↩ -

Frederick F. Ling, The Automotive Body, Springer Science, 2011.

↩ -

Haoran Hu, Rudy Smaling, Simon Baseley, Heavy-Duty Wheeled Vehicles, SAE International, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.