This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

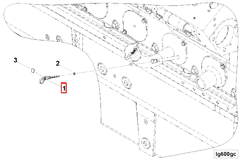

The Cummins 4100661 Dipstick is a specialized component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the measurement of oil levels within the engine, ensuring that the lubrication system operates effectively. This part is significant in the maintenance and operation of commercial trucks, as proper lubrication is vital for engine performance and longevity 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of lubricating oil. It consists of a long, slender metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick has markings that indicate the minimum and maximum acceptable oil levels. When the dipstick is removed and wiped clean, the oil level can be checked by reinserting it and then pulling it out to observe where the oil reaches in relation to these markings. This process helps ensure that the engine has the correct amount of oil for optimal lubrication 2.

Purpose of the Cummins 4100661 Dipstick

The Cummins 4100661 Dipstick plays a role in the operation of a truck by allowing for the accurate measurement of oil levels within the engine. Proper lubrication is necessary to reduce friction between moving parts, dissipate heat, and prevent wear and tear. By providing a means to check oil levels, this part helps maintain the engine’s efficiency and reliability. Regular use of the dipstick ensures that oil levels are within the recommended range, contributing to the overall health of the engine 3.

Key Features

The Cummins 4100661 Dipstick is designed with several features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions within an engine compartment. The dipstick is marked with clear, easy-to-read indicators for minimum and maximum oil levels, ensuring accurate measurements. Its design is tailored to fit securely within Cummins engines, providing a reliable seal that prevents oil leaks. Additionally, the dipstick’s handle is ergonomically shaped for ease of use, allowing for convenient and safe handling during oil level checks.

Benefits of Using the Cummins 4100661 Dipstick

Using the Cummins 4100661 Dipstick offers several advantages. Its accurate measurement capabilities ensure that oil levels are consistently monitored, which is vital for maintaining engine performance. The dipstick’s durable construction means it can withstand repeated use without degradation, providing long-term reliability. Additionally, its easy-to-read markings and ergonomic handle make it user-friendly, simplifying the process of checking oil levels and reducing the risk of errors.

Installation Process

Installing the Cummins 4100661 Dipstick involves a few straightforward steps. First, locate the dipstick tube on the engine, typically found on the valve cover. Using a socket wrench, loosen the retaining clip that holds the old dipstick in place. Carefully remove the old dipstick and insert the new Cummins 4100661 Dipstick into the tube until it is fully seated. Ensure that the dipstick is properly aligned and secured by the retaining clip. Finally, verify that the dipstick is installed correctly by checking for any gaps or misalignments.

Maintenance Tips

To ensure the longevity and accurate performance of the Cummins 4100661 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Periodically inspect the dipstick for signs of wear or damage, such as bent or corroded sections, and replace it if necessary. Additionally, ensure that the dipstick tube is free of debris and that the retaining clip is secure to prevent oil leaks.

Troubleshooting Common Issues

Common issues with the Cummins 4100661 Dipstick may include inaccurate oil level readings or difficulty in insertion. If inaccurate readings are observed, check for proper alignment and seating of the dipstick within the tube. Ensure that the engine is on a level surface when checking oil levels to obtain accurate readings. If insertion is difficult, inspect the dipstick and tube for obstructions or damage. In cases of persistent issues, consider consulting the vehicle’s service manual or a professional technician for further diagnosis 4.

Role in Preventive Maintenance

Regular use of the Cummins 4100661 Dipstick is a key component of a comprehensive preventive maintenance program for commercial trucks. By routinely checking oil levels, operators can identify potential issues early, such as oil leaks or consumption, and address them before they lead to more significant problems. This proactive approach helps maintain engine health, improve fuel efficiency, and extend the lifespan of the vehicle. Incorporating the dipstick into regular maintenance routines ensures that the engine remains well-lubricated and operates at peak performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has built a reputation for quality, reliability, and innovation in the commercial truck industry. The company is committed to providing solutions that meet the evolving needs of its customers, ensuring that their products contribute to the efficiency and sustainability of transportation and power generation systems worldwide. Cummins’ dedication to excellence is reflected in its extensive range of products, including the Cummins 4100661 Dipstick, which is designed to meet the high standards required for commercial truck applications.

Cummins Engine Dipstick Part 4100661

The Cummins part number 4100661, which is a Dipstick, is designed to be compatible with a range of Cummins engines. This includes the QSK45 and CM500 series engines. The dipstick is an essential component for checking the oil level in these engines, ensuring that the oil is at the correct level for optimal performance and longevity of the engine.

For the QSK45 series engines, the dipstick part 4100661 is engineered to fit seamlessly into the engine’s oil system. This series of engines is known for its robust design and is often used in heavy-duty applications, such as marine and industrial settings. The dipstick ensures that users can easily and accurately check the oil level, which is crucial for maintaining the engine’s efficiency and preventing potential damage from low oil levels.

Similarly, the CM500 series engines also benefit from the use of the dipstick part 4100661. This series is typically employed in on-highway and vocational applications, where reliability and performance are paramount. The dipstick’s design allows for straightforward oil level checks, ensuring that the engine operates smoothly and efficiently.

In both the QSK45 and CM500 series engines, the dipstick part 4100661 is a critical tool for maintenance. Its compatibility with these engines ensures that users can maintain the oil levels accurately, which is vital for the engine’s health and performance.

Role of Part 4100661 Dipstick in Engine Systems

The part 4100661 Dipstick is an essential component in the oil management system of an engine. It is specifically designed to interface with the oil level gauge location, ensuring accurate measurement and monitoring of the engine oil level.

When the dipstick is inserted into the oil filler tube, it provides a direct reading of the oil level within the crankcase. This reading is then conveyed to the oil level gauge, which displays the information to the operator. The dipstick’s design allows it to effectively transfer oil level data, facilitating timely maintenance and ensuring the engine operates within optimal lubrication parameters.

The interaction between the dipstick and the oil level gauge location is seamless, allowing for consistent and reliable oil level readings. This integration is vital for maintaining the engine’s performance and longevity, as it enables the operator to make informed decisions regarding oil changes and top-ups.

Conclusion

In summary, the Cummins 4100661 Dipstick plays a significant role in the engine’s oil management system by providing accurate and consistent oil level readings through its connection with the oil level gauge location. Regular use of this part ensures that the engine remains well-lubricated, which is crucial for maintaining engine health, improving fuel efficiency, and extending the lifespan of the vehicle.

-

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ -

Bennett, Sean. Modern Diesel Technology Light Duty Diesels. Cengage Learning, 2012.

↩ -

Huzij, Robert; Spano, Angelo; Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. ISF2.8 CM2220 F117, Service Manual (4388578).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.