This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

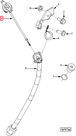

The Cummins 4318841 Dipstick is a specialized component designed for use in commercial trucks equipped with Cummins engines. Its primary function is to facilitate the measurement of engine oil levels, ensuring that the engine operates within the manufacturer’s specified parameters. Accurate oil level measurement is vital for the efficient and reliable operation of truck engines, as it helps maintain proper lubrication, cooling, and overall engine health 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engine maintenance. It consists of a long, slender metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump through a tube. The dipstick allows mechanics and operators to check the oil level by pulling it out and observing the oil mark on the stick. This process helps ensure that the engine has the correct amount of oil, which is necessary for reducing friction, dissipating heat, and protecting engine components from wear and damage 2.

Purpose of the Cummins 4318841 Dipstick

The Cummins 4318841 Dipstick plays a specific role in the operation and maintenance of truck engines by providing an accurate means to measure oil levels. This ensures that the engine maintains optimal lubrication, which is critical for its performance and longevity. By regularly checking the oil level with this dipstick, operators can prevent issues such as oil starvation, overheating, and premature engine wear.

Key Features

This Cummins part is designed with several key features to enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and wear, ensuring long-lasting performance. The dipstick is engineered to fit precisely within the engine’s oil sump, providing accurate readings. Additionally, it features clear markings and a robust handle for easy use and reading.

Benefits of Using the Cummins 4318841 Dipstick

Using the Cummins 4318841 Dipstick offers several advantages. Its accurate measurement capabilities help maintain the correct oil level, which is vital for engine health. The durable construction ensures it withstands the harsh conditions of commercial truck operations. Additionally, the ease of use and clear markings on the dipstick make it a practical tool for routine maintenance checks.

Installation Process

Installing the Cummins 4318841 Dipstick involves several steps to ensure it is correctly positioned and functions effectively. First, locate the dipstick tube on the engine. Remove the old dipstick by pulling it straight out of the tube. Insert the new Cummins 4318841 Dipstick into the tube until it is fully seated. Ensure it is pushed in until it stops to get an accurate reading. Finally, pull the dipstick out to check the oil level, wiping it clean between checks for precise measurements.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 4318841 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Inspect the dipstick periodically for signs of wear or damage, such as bent or corroded sections. If any issues are detected, replace the dipstick to maintain accurate oil level readings and ensure engine health.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is fully seated in the tube and by wiping it clean between checks. Physical damage, such as bends or corrosion, may require replacement of the dipstick to ensure accurate measurements and prevent potential engine problems.

Role in Preventive Maintenance

Regular use of the Cummins 4318841 Dipstick is a key component of a preventive maintenance strategy for truck engines. By routinely checking and maintaining the correct oil level, operators can prevent issues such as oil starvation, overheating, and engine wear. This proactive approach helps extend the engine’s lifespan and ensures reliable performance, reducing the likelihood of costly repairs and downtime.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long-standing reputation for innovation and quality in the commercial truck industry. The company is committed to providing reliable and efficient power solutions, supporting the needs of customers across various sectors, including transportation, construction, and agriculture.

Role of Part 4318841 Dipstick in Engine Systems

The part 4318841 dipstick is an integral component in the maintenance and monitoring of engine systems. It works in conjunction with several key components to ensure the engine operates efficiently and safely.

Interaction with the Oil Level

The primary function of the dipstick is to provide a means of checking the oil level within the engine. When inserted into the oil filler tube, the dipstick allows mechanics and engineers to visually assess the quantity of oil present. This is essential for maintaining the correct oil level, which is necessary for lubricating moving parts, cooling the engine, and ensuring optimal performance.

Connection to the Gauge

In some advanced engine systems, the dipstick may be linked to an oil level gauge. This gauge provides a more precise reading of the oil level, often displayed on the engine’s control panel. The dipstick, in this case, acts as a probe that sends information to the gauge, allowing for real-time monitoring of oil levels. This integration enhances the accuracy of oil level readings and facilitates timely maintenance.

Ensuring Engine Health

By regularly using the dipstick to check the oil level, engineers and mechanics can prevent issues such as oil starvation, which can lead to increased friction, overheating, and eventual engine failure. The dipstick serves as a simple yet effective tool for routine checks, enabling proactive maintenance and extending the lifespan of the engine.

Facilitating Oil Changes

During an oil change, the dipstick is used to ensure that the correct amount of new oil is added to the engine. After draining the old oil, the dipstick helps in verifying that the new oil level is within the recommended range, thus maintaining the engine’s lubrication system’s integrity.

Supporting Diagnostic Processes

In diagnostic scenarios, the dipstick can indicate potential issues by showing signs of contamination or abnormal oil levels. For instance, a milky appearance on the dipstick may suggest coolant mixing with the oil, pointing to a possible head gasket failure. Such observations aid in early detection and resolution of underlying problems.

Conclusion

In summary, the Cummins 4318841 Dipstick plays a significant role in the routine maintenance and diagnostic processes of engine systems, working alongside components like the gauge and oil level indicators to ensure the engine operates smoothly and efficiently. Regular use and maintenance of this part are essential for the longevity and reliability of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.