This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

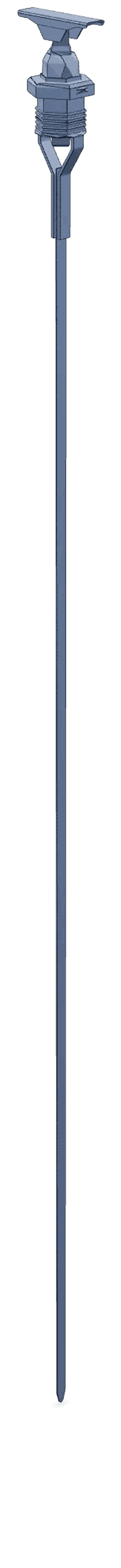

The Cummins 4914882 Dipstick is a component designed for use in commercial trucks, specifically tailored to facilitate the monitoring and maintenance of engine oil levels. Its role is significant in ensuring the engine operates within optimal parameters, thereby contributing to the overall efficiency and longevity of the vehicle 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in internal combustion engines to measure the level of lubricant within the engine. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube, and when withdrawn, the oil level can be read from markings on the rod. This process allows for the assessment of whether the oil level is within the manufacturer’s specified range, ensuring adequate lubrication and cooling of engine components 2.

Purpose of the Cummins 4914882 Dipstick

This Cummins part serves a specific function in the operation of a truck by providing a means to accurately measure the engine oil level. This measurement is crucial for maintaining proper lubrication, which in turn helps in reducing friction and wear on engine parts, ensuring efficient operation and prolonging the engine’s service life 3.

Key Features

This part is characterized by its robust design and material selection, which contribute to its performance and durability. Crafted from high-quality materials, it is resistant to corrosion and wear, ensuring longevity even in the demanding environments typical of commercial truck operations. Its design allows for precise oil level readings, facilitating effective maintenance routines 4.

Benefits of Using the Cummins 4914882 Dipstick

Utilizing this Cummins part offers several advantages. It provides accurate oil level measurements, which are critical for maintaining engine health. Its ease of use allows for quick checks, minimizing downtime during maintenance procedures. Additionally, the reliability of the dipstick ensures consistent performance, contributing to the overall efficiency of truck maintenance operations 5.

Installation Process

Installing this Cummins part involves a straightforward process. First, ensure the engine is turned off and has cooled down to avoid burns or injuries. Locate the dipstick tube, usually found near the engine’s top. Remove the old dipstick by pulling it out of the tube. Insert the new Cummins 4914882 Dipstick into the tube until it reaches the bottom, then withdraw it slightly to allow for an accurate reading. Reinsert it fully and secure it in place 6.

Maintenance Tips

To ensure the longevity and consistent performance of this Cummins part, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect the accuracy of future readings. Inspecting the dipstick for signs of wear or damage is also important, as this can impact its effectiveness. Replacing the dipstick if it shows significant wear ensures continued accurate oil level measurements 7.

Troubleshooting Common Issues

Common issues with dipsticks, such as inaccurate readings or physical damage, can often be addressed with simple solutions. Inaccurate readings may be due to incorrect installation or contamination, which can be resolved by ensuring proper installation and cleaning the dipstick regularly. Physical damage to the dipstick may require replacement to maintain accurate oil level measurements 8.

Role in Preventive Maintenance

Incorporating the use of the Cummins 4914882 Dipstick into a preventive maintenance strategy is beneficial for commercial trucks. Regular oil level checks allow for the early detection of potential issues, such as oil leaks or consumption, enabling timely interventions. This proactive approach helps in maintaining engine health, reducing the risk of unexpected breakdowns, and extending the vehicle’s operational life 9.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories, providing reliable and efficient power solutions for various applications, from on-highway to off-highway and stationary power 10.

Cummins Dipstick Part 4914882 Compatibility

The Cummins dipstick part number 4914882 is designed to be used with a variety of engine models, ensuring accurate oil level readings and facilitating proper maintenance. This dipstick is engineered to fit seamlessly into the specified engine configurations, providing reliable and precise measurements.

M11 MECHANICAL Engines

The Cummins dipstick part 4914882 is compatible with the M11 MECHANICAL engines. This compatibility ensures that mechanics and operators can easily check the oil levels, which is crucial for maintaining engine performance and longevity. The dipstick’s design aligns with the engine’s specifications, allowing for straightforward and effective oil level checks.

Group Compatibility

In addition to individual engine models, the dipstick part 4914882 is also compatible with a broader group of Cummins engines. This compatibility extends to various engine series where the design and specifications align with the requirements of the dipstick. Mechanics and technicians can rely on this part for consistent and accurate oil level readings across multiple engine types, simplifying maintenance procedures and ensuring that the engines operate within optimal parameters 11.

Role of Part 4914882 Dipstick in Engine Systems

The part 4914882 dipstick is an essential component in the arrangement of an engine’s oil system, facilitating the accurate measurement and monitoring of oil levels.

In the oil fill arrangement, the dipstick serves as a primary tool for checking the oil level within the engine. When inserted into the oil filler tube and then withdrawn, the dipstick provides a visual indication of the oil level by displaying oil marks along its length. This allows engineers and mechanics to ensure that the engine has the appropriate amount of oil, which is necessary for lubrication, cooling, and overall engine performance.

Additionally, the dipstick is integral to the maintenance routine, enabling periodic checks that help in identifying potential issues such as oil leaks or consumption. Its role in the oil fill arrangement ensures that the engine operates within optimal conditions, thereby contributing to the longevity and efficiency of the engine system 12.

Conclusion

The Cummins 4914882 Dipstick plays a crucial role in the maintenance and operation of commercial truck engines. By providing accurate oil level measurements, it ensures that engines operate within optimal conditions, contributing to their efficiency and longevity. Regular use and maintenance of this part are essential for the effective management of engine health and the prevention of unexpected breakdowns.

-

Gifford, Clive. Cars Encyclopedia. DK Publishing, 2014.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature, 2020.

↩ -

Ribbens, William B. Understanding Automotive Electronics. Elsevier Science, 2003.

↩ -

Peters, George, and Barbara J Peters. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩ -

Cummins Inc. Operation and Maintenance Manual for B6.7 CM2350 B198C, Bulletin Number 6396900.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.