This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

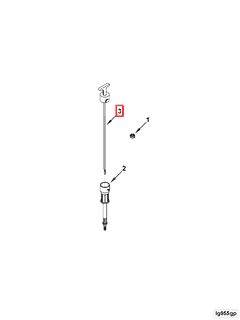

The Cummins 4936882 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the measurement of oil levels within the engine, ensuring that the lubrication system operates effectively. This part is significant in the maintenance routine of heavy-duty trucks, as proper lubrication is vital for engine performance and longevity.

Basic Concepts of a Dipstick

A dipstick is a tool used in internal combustion engines to measure the level of lubricant, typically oil. It consists of a long, slender rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s specified range, ensuring that the engine components receive adequate lubrication 1.

Purpose of the Cummins 4936882 Dipstick

The Cummins 4936882 Dipstick plays a role in the operation of a truck by providing a means to measure oil levels accurately. Proper lubrication is necessary to reduce friction between moving parts, dissipate heat, and prevent wear and tear. By ensuring that the oil level is correct, this Cummins part helps maintain the engine’s efficiency and extends its operational life.

Key Features

The Cummins 4936882 Dipstick is characterized by its robust design and the materials used in its construction. It is typically made from high-quality steel, which offers durability and resistance to the high temperatures and pressures within an engine. The dipstick may also feature a spring-loaded mechanism to ensure a secure fit within the engine’s oil tube, preventing oil leaks. Additionally, it has clear and precise markings for accurate oil level readings.

Benefits of Using the Cummins 4936882 Dipstick

Utilizing the Cummins 4936882 Dipstick offers several advantages. Its design ensures accurate oil level measurements, which is crucial for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to the harsh conditions within an engine. Furthermore, the dipstick is designed for ease of use, allowing for quick and straightforward oil level checks during routine maintenance.

Installation Process

Installing the Cummins 4936882 Dipstick involves a few straightforward steps. First, ensure the engine is turned off and has cooled down to avoid burns from hot engine components. Locate the dipstick tube, usually found near the engine’s top. Remove the old dipstick by pulling it straight out of the tube. Insert the new Cummins 4936882 Dipstick into the tube until it reaches the bottom, then withdraw it slightly to ensure a proper fit. Push it back in fully and secure it if necessary. Finally, check for any oil leaks around the dipstick tube.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate oil level readings and physical damage. Inaccurate readings may result from a bent dipstick or incorrect installation. Ensuring the dipstick is straight and fully seated can resolve this. Physical damage, such as cracks or bends, may require replacement of the dipstick to maintain accurate readings and prevent oil leaks.

Maintenance Tips

To ensure the longevity and reliable performance of the Cummins 4936882 Dipstick, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect the accuracy of future readings. Inspect the dipstick for signs of wear or damage during routine engine checks. If any issues are detected, consider replacing the dipstick to maintain the integrity of the oil level measurement system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history dating back to 1919, Cummins has established a reputation for innovation and quality in the automotive industry, particularly in the production of diesel engines and components. The company’s commitment to excellence and customer satisfaction has made it a trusted name among professionals in the heavy-duty truck and engine sectors.

Cummins Engine Dipstick Compatibility

The Cummins part 4936882, a Dipstick, is designed to fit into specific models of Cummins engines. This dipstick is essential for checking the oil level and ensuring the engine is properly lubricated. Below is a detailed description of how this dipstick fits with the listed engines:

-

QSB6.7 CM2250 and QSB6.7 CM2350 B105: These engines share a similar design and architecture, making the dipstick 4936882 compatible with both. The dipstick is engineered to fit snugly into the designated oil level check port on these engines, ensuring accurate readings and ease of use.

-

QSB6.7 CM850 (CM2850): This engine model also accommodates the dipstick 4936882. The design of the dipstick ensures it fits perfectly into the oil level check port, providing reliable oil level readings.

-

QSB7 CM2880 B117: The dipstick 4936882 is compatible with this engine as well. It is designed to fit into the oil level check port, ensuring that users can easily and accurately check the oil levels.

Each of these engines has been designed to work seamlessly with the dipstick 4936882, ensuring that maintenance and oil level checks are straightforward and reliable. This compatibility across different engine models highlights the versatility and precision of Cummins’ design.

Role of Part 4936882 Dipstick in Engine Systems

The part 4936882 dipstick is a component in the maintenance and operation of engine systems, working in conjunction with the oil level gauge to ensure optimal performance and longevity of the engine.

Interaction with the Oil Level Gauge

The dipstick, specifically part 4936882, is designed to interface seamlessly with the oil level gauge. When inserted into the engine’s oil filler neck, the dipstick provides a physical measurement of the oil level. This measurement is then visually interpreted by the oil level gauge, which translates the oil height on the dipstick into a readable format for the operator. This interaction ensures that the engine maintains the correct oil level, which is vital for lubrication, cooling, and overall engine health.

Ensuring Proper Lubrication

By accurately measuring the oil level, the dipstick plays a significant role in ensuring that the engine receives adequate lubrication. Proper lubrication is necessary to reduce friction between moving parts, prevent wear and tear, and maintain efficient operation. The dipstick’s precise measurement capabilities help in avoiding both overfilling and underfilling of oil, which can lead to severe engine damage 2.

Facilitating Regular Maintenance

Regular checks using the dipstick are a fundamental part of routine engine maintenance. Mechanics and engineers rely on the dipstick to perform quick and accurate oil level checks during service intervals. This regular monitoring helps in identifying potential issues early, such as oil leaks or consumption, allowing for timely interventions and prolonging the engine’s service life.

Supporting Diagnostic Processes

In diagnostic scenarios, the dipstick serves as a primary tool for assessing the engine’s condition. The color and consistency of the oil on the dipstick can provide insights into the engine’s internal health. For instance, dark or gritty oil may indicate contamination or the need for an oil change, while a milky appearance could signal a coolant leak into the oil system. These visual cues are invaluable for diagnosing underlying issues and informing repair strategies 3.

Enhancing Operational Efficiency

The dipstick’s role extends beyond mere measurement; it enhances operational efficiency by ensuring that the engine operates within its specified oil level parameters. This consistency in oil level contributes to stable engine performance, fuel efficiency, and reduced emissions. Engineers and mechanics can thus rely on the dipstick to maintain engine efficiency across various operating conditions.

Conclusion

In summary, the Cummins 4936882 Dipstick is integral to the engine system, working in tandem with the oil level gauge to maintain proper lubrication, facilitate regular maintenance, support diagnostic processes, and enhance operational efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.