This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

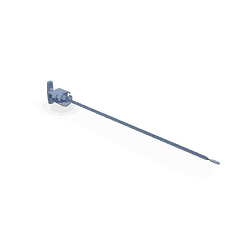

The Cummins 4944013 Dipstick is a component designed for use in commercial trucks, specifically for monitoring engine oil levels. Its role in the maintenance and operation of these vehicles is significant, as it ensures that the engine remains properly lubricated, which is vital for performance and longevity 2.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of oil. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then removed, the oil level can be read from the markings on the dipstick, indicating whether the oil is at the appropriate level 1.

Purpose of the 4944013 Dipstick

The 4944013 Dipstick serves a specific function in the operation of a truck by allowing for the measurement of oil levels within the engine. This measurement is important for ensuring that there is sufficient lubrication for the engine’s moving parts, which helps to reduce friction and wear. Proper lubrication is also important for heat dissipation and for carrying away contaminants from the engine 2.

Key Features

The Cummins 4944013 Dipstick is constructed from materials that offer durability and resistance to the high temperatures and pressures found within an engine. Its length is designed to reach the oil sump of the specific engines it is intended for, and it features clear, easy-to-read markings for accurate oil level assessment. The design may also include features that enhance its performance, such as a ribbed handle for a secure grip 1.

Benefits

Using the 4944013 Dipstick provides several advantages. It offers accurate oil level measurements, which are important for maintaining engine health. The design of the dipstick also contributes to ease of use, allowing for quick and efficient checks during maintenance routines. Consistent and accurate oil level readings can contribute to the longevity of the engine by ensuring that it is always properly lubricated 2.

Installation Process

To install the 4944013 Dipstick, one should first ensure that the engine is cool and that the vehicle is parked on a level surface. The old dipstick should be removed by unscrewing the tube from the engine block. The new dipstick is then inserted into the tube and secured in place. It is important to use the correct tools and to follow any specific instructions provided by the manufacturer to ensure a proper fit 1.

Usage Instructions

To use the 4944013 Dipstick for checking oil levels, the engine should be turned off and allowed to settle for a few minutes. The dipstick is removed from the tube, wiped clean, reinserted fully, and then removed again to check the oil level against the markings. For an accurate reading, it is best practice to check the oil level when the engine is cold or after it has been running and has settled for a few minutes 2.

Troubleshooting Common Issues

Common issues with the 4944013 Dipstick may include inaccurate readings or physical damage to the dipstick. Inaccurate readings can often be resolved by ensuring the dipstick is fully seated in the tube and by checking the oil level at the correct time. Physical damage may require replacement of the dipstick. Regular inspections can help identify wear or damage early 1.

Maintenance Tips

To maintain the 4944013 Dipstick, it should be cleaned after each use to remove any oil residue that may affect the accuracy of future readings. Periodic inspections for signs of wear or damage are also recommended. If the dipstick becomes bent or shows signs of significant wear, it should be replaced to ensure continued accurate oil level readings 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a broad product range, Cummins is well-regarded in the commercial truck industry for its quality and reliability. The company’s commitment to customer success is reflected in its extensive line of parts and services designed to meet the needs of commercial vehicle operators.

Cummins Engine Dipstick 4944013 Compatibility

The Cummins part number 4944013, a Dipstick, is designed to fit into a range of Cummins diesel engines. This dipstick is integral for checking the oil level in these engines, ensuring that the oil is at the correct level for optimal performance and engine longevity.

Compatible Engines

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

- QSB7 CM2880 B117

The dipstick 4944013 is engineered to provide an accurate reading of the oil level in these engines. It is essential to use the correct dipstick for each engine model to ensure precise measurements. The design of the dipstick ensures it fits snugly into the designated oil level check port on each engine, allowing for easy and reliable oil level checks.

Grouping of Compatible Engines

-

QSB6.7 Series:

- QSB6.7 CM2250

- QSB6.7 CM2350 B105

- QSB6.7 CM850 (CM2850)

-

QSB7 Series:

- QSB7 CM2880 B117

These engines, while part of the same family, may have slight variations in their oil systems. Therefore, it is crucial to use the dipstick that is specifically designed for each engine model to ensure compatibility and accuracy. The dipstick 4944013 is tailored to fit the oil level check ports of these engines, ensuring that users can perform oil level checks with confidence.

By using the correct dipstick, engine owners and operators can maintain their engines’ health and performance, avoiding potential issues that may arise from incorrect oil levels.

Role of Part 4944013 Dipstick in Engine Systems

The part 4944013 dipstick is an essential component in the oil management system of an engine. It works in conjunction with the oil level gauge to provide accurate readings of the engine oil level.

When the dipstick is inserted into the oil filler tube, it comes into direct contact with the engine oil. Upon removal, the oil level can be read from the markings on the dipstick, which correspond to minimum and maximum oil levels. This data is then relayed to the oil level gauge, which may be mechanical or digital, depending on the engine system.

The dipstick also plays a part in the ventilation of the crankcase. As it is not a tight fit within the filler tube, it allows for the escape of pressure that builds up within the crankcase during engine operation. This is important for maintaining a stable operating environment for the engine.

Furthermore, the dipstick aids in the process of oil changes. It provides a reference point for the quantity of oil that needs to be drained and subsequently refilled. This ensures that the engine is neither overfilled nor underfilled, both of which can lead to operational issues.

Conclusion

In summary, the part 4944013 dipstick is a simple yet integral component in the maintenance and operation of engine systems. Its interaction with the oil level gauge and its role in crankcase ventilation and oil change processes underscore its importance in ensuring the engine operates efficiently and effectively.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.