This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4947030 Dipstick is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the monitoring of engine oil levels, ensuring that the engine operates within the optimal lubrication parameters. This Cummins part is integral to the maintenance routine of commercial trucks, contributing to the overall efficiency and longevity of the engine.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in engine maintenance. It consists of a long, slender metal or plastic rod with graduated markings. The dipstick is inserted into the engine’s oil sump through a designated tube. Once inserted and then removed, the oil level can be read from the markings on the dipstick, indicating whether the oil level is within the acceptable range. This process is fundamental for maintaining proper engine lubrication, which is essential for engine health and performance 1.

Purpose of the Cummins 4947030 Dipstick

The Cummins 4947030 Dipstick plays a specific role in the engine’s lubrication system by allowing for the precise measurement of oil levels. Proper lubrication is necessary to reduce friction between moving parts, dissipate heat, and prevent wear and tear. By providing an accurate reading of the oil level, this dipstick ensures that the engine maintains the correct amount of lubrication, thereby supporting efficient operation and prolonging the engine’s lifespan 2.

Key Features

The Cummins 4947030 Dipstick is characterized by several key features that enhance its performance. It is constructed from high-quality materials to withstand the harsh conditions within a commercial truck engine. The design includes clear, easy-to-read markings for accurate oil level assessment. Additionally, the dipstick may feature a robust handle for ease of use and a secure fitting to prevent oil leaks.

Benefits of Using the Cummins 4947030 Dipstick

Utilizing the Cummins 4947030 Dipstick offers several advantages. Its design ensures accurate oil level measurements, which is vital for maintaining engine health. The durability of the materials used means it can withstand the rigors of commercial truck operation. Furthermore, its ease of use simplifies the maintenance process, allowing for quick and efficient oil level checks.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings or difficulty in insertion/removal. To address these, ensure the dipstick is fully seated when taking a reading and clean it regularly to remove any debris that may affect accuracy. Maintenance practices such as checking for wear and ensuring a tight fit in the tube can help maintain the dipstick’s performance and longevity 3.

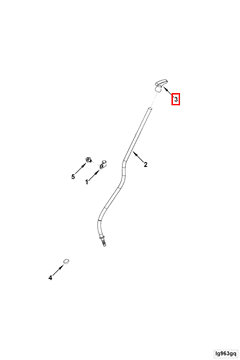

Installation Process

Installing the Cummins 4947030 Dipstick involves a few straightforward steps. First, locate the dipstick tube on the engine. Remove the old dipstick by pulling it out of the tube. Insert the new Cummins 4947030 Dipstick fully into the tube until it stops. Then, withdraw it slightly to take an accurate reading of the oil level. Ensure the dipstick is reinserted fully after checking the oil level to prevent oil leaks.

Common Misconceptions

There are several misconceptions about dipsticks and their use. One common misunderstanding is that any dipstick can be used interchangeably across different engines. It is important to use the correct dipstick specified by the engine manufacturer to ensure accurate readings and proper fit. Another misconception is that dipsticks do not require maintenance. Regular cleaning and inspection can help maintain their accuracy and functionality.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. Their commitment to excellence is reflected in their product line, including the Cummins 4947030 Dipstick, which is designed to meet the demanding requirements of commercial truck engines.

Cummins Dipstick 4947030 Compatibility

The Cummins Dipstick part number 4947030 is designed to be compatible with a range of Cummins engines, ensuring accurate oil level readings and maintenance ease. This dipstick is specifically engineered to fit seamlessly with the following Cummins engine models:

- ISB/ISD4.5 CM2150 B119

- ISBE4 CM850

These engines, while differing in their specific configurations and applications, share a common design feature that allows the dipstick to function effectively. The dipstick’s design ensures it can be inserted into the designated oil level check port on these engines, providing a clear and precise reading of the oil level. This compatibility is crucial for maintaining engine health and performance, as it allows for timely and accurate oil level checks, which are essential for preventing engine damage due to low oil levels.

Role of Part 4947030 Dipstick in Engine Systems

The part 4947030 Dipstick is a component in the oil level gauge system of an engine. Its primary function is to provide a means for checking the oil level within the engine. This is achieved through a simple yet effective mechanism where the dipstick is inserted into the oil filler tube and then withdrawn to observe the oil level against the markings on the dipstick.

When the dipstick is inserted into the oil filler tube, it reaches down to the oil pan where the engine oil is stored. Upon withdrawal, the oil adheres to the dipstick, allowing the user to visually inspect the oil level. The markings on the dipstick indicate the minimum and maximum oil levels, ensuring that the engine operates within safe parameters.

The dipstick also plays a role in the breather system of the engine. As the engine operates, it produces gases that need to be vented from the crankcase. The dipstick tube serves as a breather passage, allowing these gases to escape while preventing oil from being forced out under pressure. This helps maintain a stable oil level and prevents contamination of the oil.

Furthermore, the dipstick is integral to the oil change process. Before draining the oil, the dipstick is removed to allow access to the oil drain plug. After the oil has been changed, the dipstick is reinserted to ensure the oil filler tube is sealed, preventing oil leaks and maintaining the integrity of the oil system.

Conclusion

In summary, the part 4947030 Dipstick is a multifaceted component that ensures the proper functioning of the oil level gauge, contributes to the breather system, and facilitates the oil change process, all of which are vital for the overall health and performance of the engine.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality (Elsevier, 2021).

↩ -

Hannes Hick, Klaus Kupper, and Helfried Sorger, Systems Engineering for Automotive Powertrain Development (Springer, 2021).

↩ -

Robert Bosch GmbH, Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid Drive 5th Edition (Springer Vieweg, 2007).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.