Introduction

The Cummins 4962614 Dipstick is a component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the monitoring of oil levels within the engine, which is a fundamental aspect of maintaining the engine’s performance and longevity. Regular checks using this dipstick allow for the timely identification of low oil levels, which can prevent engine damage and ensure optimal operation 1.

Basic Concepts of a Dipstick

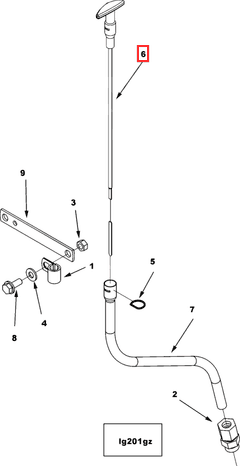

A dipstick is a simple yet vital tool used in internal combustion engines to measure the level of lubricant, typically oil, within the engine. It consists of a long, slender metal or plastic rod with a handle at one end. The rod is inserted into the engine’s oil sump through a tube. Once inserted and then withdrawn, the oil level can be read from the markings on the dipstick, which indicate the minimum and maximum acceptable oil levels 2.

Purpose of the Cummins 4962614 Dipstick

The Cummins 4962614 Dipstick is specifically engineered to serve as an accurate gauge for oil levels in Cummins engines. It plays a role in the maintenance routine by allowing operators to check the oil level regularly. This is important for ensuring that the engine has sufficient lubrication, which is necessary for reducing friction between moving parts, cooling the engine, and cleaning internal components 3.

Key Features

This Cummins part is constructed from durable materials to withstand the harsh conditions within an engine compartment. It features a robust design that includes a corrosion-resistant coating to enhance its longevity. The dipstick is also equipped with clear and precise markings for easy reading of the oil level. Its length is tailored to fit the specific design of Cummins engines, ensuring an accurate measurement.

Benefits

Using the Cummins 4962614 Dipstick offers several advantages. Its design ensures accurate fluid level measurement, which is crucial for maintaining engine health. The durability of the materials used means it can withstand frequent use without degradation. Additionally, the ease of use, with its straightforward design and clear markings, makes it a practical tool for regular maintenance checks.

Installation Process

To install the Cummins 4962614 Dipstick, first, ensure the engine is turned off and has cooled down to avoid burns. Locate the dipstick tube, which is usually found near the top of the engine. Remove the old dipstick by pulling it straight out of the tube. Insert the new dipstick fully into the tube until it is seated, then withdraw it slightly to ensure it is properly installed.

Usage Instructions

To use the Cummins 4962614 Dipstick for checking oil levels, start by ensuring the truck is on a level surface and the engine is off. Pull the dipstick out of the tube, wipe it clean with a lint-free cloth, reinsert it fully, and then withdraw it again. Check the oil level against the markings on the dipstick. If the level is below the minimum mark, add the appropriate type and amount of oil as specified in the truck’s maintenance manual.

Troubleshooting and Maintenance

If the Cummins 4962614 Dipstick provides inaccurate readings, check for proper seating within the tube and ensure there is no obstruction. Regular cleaning of the dipstick with a lint-free cloth after each use can prevent buildup that may affect readings. Inspect the dipstick for signs of wear or damage, and replace it if necessary to maintain accurate measurements.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities and dealerships. The company is committed to powering a more prosperous world by providing reliable and efficient power solutions.

ISM CM570, ISM CM570/870, ISM CM876 Dipstick Compatibility

The Cummins part number 4962614, which is a Dipstick, is designed to be compatible with several of the ISM series engines, including the ISM CM570, ISM CM570/870, and ISM CM876. This part is essential for maintaining the proper oil levels in these engines, ensuring optimal performance and longevity.

For the ISM CM570 and ISM CM570/870 engines, the dipstick is engineered to fit seamlessly into the designated oil level check port. This compatibility ensures that users can accurately measure the oil level, which is crucial for engine health. The dipstick’s design allows for easy insertion and removal, providing a clear reading of the oil level.

Similarly, the ISM CM876 engine also utilizes the Cummins part number 4962614 dipstick. This part is specifically tailored to fit the oil level check port of the ISM CM876, ensuring that users can perform regular oil level checks with ease and precision. The dipstick’s design is consistent across these engines, facilitating straightforward maintenance procedures.

By using the Cummins part number 4962614 dipstick, users of the ISM CM570, ISM CM570/870, and ISM CM876 engines can ensure that they are maintaining their engines according to the manufacturer’s specifications. This compatibility underscores Cummins’ commitment to providing reliable and high-quality parts for their engines.

Role of Part 4962614 Dipstick in Engine Systems

The part 4962614 dipstick is an essential component in the oil level gauge system of an engine. It serves as the primary tool for measuring the amount of oil within the engine’s crankcase.

When inserted into the oil filler neck, the dipstick provides a direct reading of the oil level. This reading is vital for maintaining the engine’s lubrication system, ensuring that all moving parts are adequately coated with oil to reduce friction and wear.

The dipstick is typically marked with minimum and maximum level indicators, allowing for a quick assessment of whether the oil level is within the acceptable range.

Regular checks using the dipstick help in identifying potential leaks or excessive oil consumption, which could indicate underlying issues such as worn piston rings or valve guide seals.

In addition to its primary function, the dipstick also allows for the introduction of oil additives or treatments directly into the crankcase, enhancing the oil’s performance and protecting the engine’s internal components.

Overall, the dipstick is a simple yet indispensable part of the engine’s maintenance routine, facilitating the monitoring and management of the oil level to ensure optimal engine performance and longevity.

Conclusion

The Cummins 4962614 Dipstick is a critical component for maintaining the health and performance of Cummins engines. Its accurate measurement capabilities, durable construction, and ease of use make it an essential tool for regular engine maintenance. By ensuring proper oil levels, this part contributes to the longevity and efficiency of the engine, underscoring the importance of regular checks and maintenance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.