This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

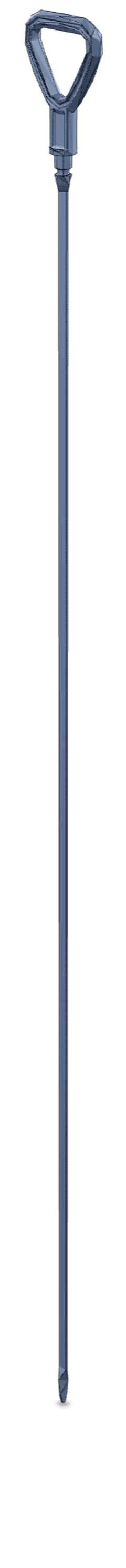

The Cummins 4982795 Dipstick is a component designed for use in heavy-duty trucks, specifically tailored to facilitate the maintenance and operation of these vehicles. Its role is significant in ensuring that the engine operates within optimal conditions by allowing for the accurate measurement of oil levels. This, in turn, helps in maintaining proper lubrication, which is vital for the longevity and efficiency of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engines to measure the level of lubricant, typically oil. It consists of a long, slender rod with a handle at one end, which is inserted into the engine’s oil reservoir. Once inserted, the dipstick is withdrawn, and the oil level can be read from the markings along its length. This process allows for the assessment of whether the oil level is within the manufacturer’s recommended range, ensuring that the engine remains adequately lubricated 2.

Purpose of the Cummins 4982795 Dipstick

The Cummins 4982795 Dipstick serves a specific function in the operation of a truck by enabling the measurement of oil levels within the engine. Proper lubrication is fundamental to the engine’s performance and longevity, as it reduces friction between moving parts, dissipates heat, and helps in cleaning the engine internally. The dipstick plays a role in this process by providing a straightforward method for checking oil levels, thereby ensuring that the engine operates under optimal conditions 3.

Key Features

The Cummins 4982795 Dipstick is characterized by its robust design and the materials used in its construction, which are chosen for their durability and resistance to the harsh conditions within an engine. It features clear markings for easy reading of oil levels and is designed to fit securely within the engine’s oil reservoir, ensuring accurate measurements. Additionally, its construction may include features that enhance its performance, such as a textured handle for a firm grip and a tip designed to resist bending or breaking 4.

Benefits of Using the Cummins 4982795 Dipstick

Utilizing the Cummins 4982795 Dipstick offers several advantages. Its design ensures accuracy in oil level measurement, which is crucial for maintaining engine health. The materials used in its construction contribute to its durability, making it a reliable tool for frequent use. Furthermore, its ease of use, with clear markings and a secure fit, simplifies the process of checking oil levels, reducing the time and effort required for maintenance tasks.

Installation and Usage

To install and use the Cummins 4982795 Dipstick, follow these steps: First, ensure the truck is on a level surface and the engine is off to obtain an accurate reading. Locate the dipstick tube, usually found near the engine’s center. Pull out the dipstick, wipe it clean with a cloth, reinsert it fully, then pull it out again to check the oil level against the markings. For optimal performance, ensure the dipstick is reinserted fully after checking the oil level.

Maintenance and Care

To ensure the longevity and reliable performance of the Cummins 4982795 Dipstick, regular maintenance is recommended. This includes cleaning the dipstick after each use to remove any oil residue, which can affect the accuracy of future readings. Inspect the dipstick for any signs of wear or damage, such as bending or cracking, and replace it if necessary to maintain accurate oil level measurements.

Troubleshooting Common Issues

Common issues with dipsticks may include inaccurate readings due to contamination or damage. To address these, ensure the dipstick is clean before taking a reading and check for any physical damage that may affect its performance. If the dipstick appears worn or damaged, replacing it with a new one is advisable to ensure accurate oil level measurements.

Safety Considerations

When using and maintaining the Cummins 4982795 Dipstick, it is important to observe safety practices to prevent accidents and ensure personal safety. Always ensure the engine is off and the vehicle is on a level surface before checking the oil level. Use caution when handling the dipstick to avoid burns from hot engine components and wear appropriate protective gear, such as gloves, to protect your hands.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the production of diesel engines and related components. Their commitment to excellence and customer satisfaction has made them a preferred choice for heavy-duty applications, including trucks and industrial equipment.

Compatibility of Cummins 4982795 Dipstick

The Cummins part number 4982795, which is a Dipstick, is designed to be compatible with a range of Cummins engines. This dipstick is engineered to fit seamlessly with the following engines:

- D4.0 CM2620 D103B

- F3.8 CM2620 F137B

- F4.5 CM2620 F139B

- F4.5 CM2620 F141C

- ISB4.5 CM2350 B104

- ISF3.8 CM2220 AN

- ISF3.8 CM2220 F103

- ISF4.5 CM2220 F123

- QSF3.8 CM2880 F112

This compatibility ensures that the dipstick can be used across various engine models, providing a standardized tool for checking oil levels. The design of the dipstick is such that it can be easily inserted into the designated oil check port of these engines, allowing for accurate and convenient oil level monitoring.

Role of 4982795 Dipstick in Engine Systems

The 4982795 dipstick is a critical component in the monitoring and maintenance of engine systems. It works in conjunction with the oil level gauge and lubricating oil gauge to ensure the engine operates within optimal conditions.

Interaction with Oil Level Gauge

The dipstick interfaces directly with the oil level gauge. When inserted into the engine, the dipstick collects a sample of the engine oil. Upon removal, the oil level can be read against the markings on the dipstick, providing a quick and reliable method for the oil level gauge to assess whether the oil is within the required range. This interaction is vital for preventing both overfilling and underfilling of the engine oil, which can lead to inefficient engine performance and potential damage.

Contribution to Lubricating Oil Gauge

In more advanced engine systems, the dipstick also plays a role in conjunction with the lubricating oil gauge. This gauge often requires precise data on the oil’s condition and level to provide accurate readings and alerts. The dipstick, by offering a direct measurement of the oil level, supports the lubricating oil gauge in delivering consistent and reliable data. This ensures that the lubricating oil gauge can effectively monitor the viscosity and cleanliness of the oil, contributing to the overall health and longevity of the engine.

Overall System Integration

In summary, the 4982795 dipstick is a fundamental component that enhances the functionality of both the oil level gauge and the lubricating oil gauge. Its accurate readings enable these gauges to perform their roles effectively, ensuring that the engine remains well-lubricated and operates efficiently. The dipstick’s simple yet effective design makes it an indispensable part of routine engine maintenance and monitoring.

Conclusion

The Cummins 4982795 Dipstick is an essential tool for maintaining the optimal performance and longevity of heavy-duty truck engines. Its accurate measurement of oil levels ensures proper lubrication, which is critical for engine efficiency and durability. Regular maintenance and proper usage of this part contribute to the overall health and reliability of the engine system.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Zhan, Quansheng, Eben, Shengbo, and Deng, Li Kun. Automotive Heating Ventilation and Air Conditioning. Jones Bartlett Learning, 2018.

↩ -

Peters, George, and Peters, Barbara J. Automobile Vehicle Safety. CRC Press, 2002.

↩ -

Miedema, S. A., and Lu, Z. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.