This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4996538 Dipstick is a component designed for use in heavy-duty trucks, specifically tailored to facilitate the maintenance and operation of these vehicles. Its role is integral to ensuring the engine operates within optimal parameters by allowing for the accurate measurement of oil levels, which is vital for the lubrication system of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a tool used in internal combustion engines to measure the level of lubricant within the engine’s oil reservoir. It operates on a straightforward principle: a long, thin rod is inserted into the oil reservoir, and upon removal, the oil level can be read from markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s recommended range, ensuring the engine remains properly lubricated 2.

Purpose of the Cummins 4996538 Dipstick

The Cummins 4996538 Dipstick serves a specific function in the operation of heavy-duty trucks. It is designed to measure the oil level within the engine, ensuring that there is sufficient lubrication for all moving parts. Proper lubrication is key to reducing friction, wear, and heat within the engine, contributing to its efficiency and longevity 3.

Key Features

The Cummins 4996538 Dipstick is characterized by its robust design and the materials used in its construction. It is made from high-quality steel, ensuring durability and resistance to the high temperatures and pressures within the engine compartment. Its design includes precise markings for oil level measurement, enhancing accuracy. Additionally, the dipstick may feature a handle for ease of use, allowing for safe and convenient checking of oil levels 4.

Benefits of Using the Cummins 4996538 Dipstick

Utilizing the Cummins 4996538 Dipstick offers several advantages. Its accurate measurement capabilities ensure that oil levels are maintained within the optimal range, contributing to engine health. The durability of the dipstick means it can withstand the demanding conditions of heavy-duty truck operation. Furthermore, its design facilitates ease of use, making routine maintenance checks straightforward for operators 5.

Troubleshooting and Maintenance

Common issues with dipsticks may include inaccurate readings due to wear or contamination. To troubleshoot, ensure the dipstick is clean and free from debris before taking a reading. Regular maintenance involves checking the dipstick for signs of wear or damage and ensuring it is securely fitted in its tube. Proper care of the dipstick contributes to the accuracy of oil level readings and the overall maintenance of the engine .

Installation and Usage

Installing the Cummins 4996538 Dipstick involves inserting it fully into its designated tube within the engine compartment, then withdrawing it to check the oil level. It is important to follow the manufacturer’s guidelines for checking oil levels, which typically involve warming the engine to operating temperature, turning it off, waiting a few minutes, and then checking the oil level with the dipstick. This process ensures an accurate reading and proper maintenance of the engine’s lubrication system .

Safety Considerations

When using the Cummins 4996538 Dipstick, it is important to observe safety precautions to avoid injury or damage to the engine. Ensure the engine is turned off and has cooled sufficiently before checking the oil level. Handle the dipstick carefully to avoid burns from hot engine components. Additionally, be mindful of the engine’s moving parts and hot surfaces when accessing the dipstick tube .

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a key player in the automotive industry, particularly in the production of diesel engines and components. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry, providing solutions that power a variety of applications, from heavy-duty trucks to industrial equipment .

Cummins Engine Dipstick Compatibility

The Cummins part number 4996538, a Dipstick, is designed to fit a variety of Cummins engines. Below is a detailed description of the compatibility of this dipstick with the listed engine models:

ISC CM850, ISL CM2150, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250

The dipstick 4996538 is compatible with the ISC CM850, ISL CM2150, ISL G CM2180, ISL9 CM2150 SN, and ISL9 CM2250 engines. These engines are part of the Cummins ISL and ISC series, known for their reliability and performance in various applications. The dipstick is engineered to provide accurate oil level readings for these engines, ensuring optimal engine performance and longevity.

QSL8.9 CM2150 L141, QSL9 CM850 (CM2850)

The dipstick 4996538 also fits the QSL8.9 CM2150 L141 and QSL9 CM850 (CM2850) engines. These engines are part of the Cummins QSL series, which is designed for heavy-duty applications. The dipstick ensures that users can easily and accurately check the oil levels, which is crucial for maintaining the engine’s health and efficiency.

L8.9G CMOH2.0 L125B

The Cummins part number 4996538 is also suitable for the L8.9G CMOH2.0 L125B engine. This engine is part of the Cummins L series, known for its durability and power. The dipstick is designed to provide precise oil level readings, helping to prevent engine damage due to low oil levels.

Each of these engines benefits from the use of the dipstick 4996538, ensuring that users can maintain their engines effectively and efficiently.

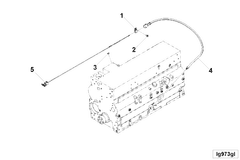

Role of Part 4996538 Dipstick in Engine Systems

The part 4996538 dipstick is a component in the oil level gauge system of an engine. It serves as the primary tool for measuring the amount of oil present within the engine’s crankcase.

When inserted into the oil filler neck, the dipstick comes into direct contact with the oil. Upon withdrawal, the oil level is indicated by the markings on the dipstick, which correspond to minimum and maximum oil levels. This data is vital for maintaining the engine’s lubrication system, ensuring that all moving parts are adequately coated with oil to reduce friction and wear.

The dipstick also plays a role in the overall health monitoring of the engine. By regularly checking the oil level with the dipstick, engineers and mechanics can detect anomalies such as oil leaks or excessive oil consumption, which may indicate underlying issues within the engine.

Furthermore, the dipstick allows for the inspection of the oil’s condition. The color and consistency of the oil on the dipstick can provide insights into the oil’s degradation over time, informing decisions on whether an oil change is necessary.

Conclusion

In summary, the Cummins 4996538 Dipstick is integral to the maintenance and monitoring of the engine’s oil level gauge, contributing to the engine’s longevity and performance. Its robust design, accurate measurement capabilities, and ease of use make it a valuable tool for maintaining heavy-duty trucks.

-

Sander, F. (2007). Diesel Mechanics, First Edition. Global Media.

↩ -

Reif, K. (2015). Gasoline Engine Management Systems and Components. Springer Vieweg.

↩ -

Hilgers, M. (2023). Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature.

↩ -

Stiesch, G. (2003). Modeling Engine Spray and Combustion Processes. Springer Verlag.

↩ -

Cummins Inc. (n.d.). General Information, Bulletin Number 4021632, Operation and Maintenance Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.