This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

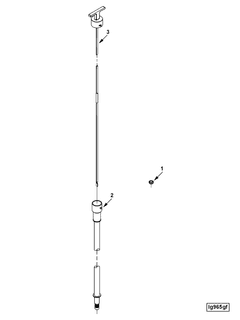

The Cummins 5260645 Dipstick is a specialized component designed for use in commercial trucks. Its primary function is to facilitate the measurement of fluid levels within the engine, ensuring that the engine operates within optimal parameters. This part is integral to the routine maintenance and operational efficiency of commercial trucks, providing a straightforward yet vital tool for engine care.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in the maintenance of truck engines. It consists of a long, slender metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil reservoir. The dipstick functions by allowing technicians to check the level and condition of the engine oil. This is achieved by withdrawing the dipstick, wiping it clean, reinserting it, and then removing it again to observe the oil level and its condition. Regular checks using a dipstick help in maintaining the engine’s health by ensuring that the oil level is adequate and that the oil itself is in good condition 1.

Purpose of the Cummins 5260645 Dipstick

This Cummins part plays a specific role in the operation and maintenance of truck engines. It is designed to provide accurate readings of the engine oil level, which is vital for the engine’s lubrication system. Proper lubrication is necessary to reduce friction between moving parts, dissipate heat, and remove contaminants from the engine. By ensuring the oil level is correct, the dipstick contributes to the engine’s longevity and performance 2.

Key Features

The Cummins 5260645 Dipstick is characterized by several key features. It is constructed from durable materials to withstand the harsh conditions within a truck engine. The design includes a clearly marked scale for precise oil level readings. Additionally, the dipstick may feature a unique shape or design that is tailored to fit specific Cummins engines, ensuring a snug fit and accurate readings.

Benefits

Using the Cummins 5260645 Dipstick offers several benefits. Its design ensures accurate fluid level measurement, which is crucial for maintaining engine health. The materials used in its construction contribute to its durability, allowing it to withstand the rigors of commercial truck use. Furthermore, the dipstick is easy to use, making routine checks a straightforward part of maintenance routines.

Installation Process

Installing the Cummins 5260645 Dipstick involves several steps. First, locate the dipstick tube in the engine. Remove the old dipstick by pulling it straight out of the tube. Insert the new 5260645 into the tube until it is fully seated. Ensure it is properly aligned and seated to avoid inaccurate readings. Finally, check the installation by pulling the dipstick out slightly and ensuring it slides in and out smoothly.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 5260645 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Periodically inspect the dipstick for signs of wear or damage. If the dipstick becomes bent or shows signs of significant wear, it should be replaced to ensure accurate readings.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings due to a bent or misaligned dipstick, or contamination of the oil level indicator. To address these issues, ensure the dipstick is properly seated and aligned within the tube. If the dipstick is bent, it should be replaced. Regularly checking the condition of the oil and the dipstick can help prevent these issues.

Safety Considerations

When using and maintaining the Cummins 5260645 Dipstick, several safety practices should be followed. Always ensure the engine is cool before checking the oil level to avoid burns. Use caution when handling the dipstick to prevent injury. Additionally, dispose of used oil and cleaning materials according to local regulations to protect the environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. Founded in 1919, Cummins has a long history of innovation and excellence in the commercial truck industry. The company is known for its commitment to quality, reliability, and customer satisfaction, making it a trusted name in the industry.

Cummins Engine Dipstick Compatibility

The Cummins part number 5260645, which is a Dipstick, is compatible with a variety of Cummins engines. This dipstick is designed to fit seamlessly into the engine’s oil system, allowing for accurate oil level checks. Below is a detailed breakdown of the engines that this dipstick fits:

ISC Series Engines

- ISC CM2150

- ISC8.3 CM2250

- QSL8.9 CM2150 L141

ISL Series Engines

- ISL CM2150

- ISL G CM2180

- ISL9 CM2150 SN

- ISL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

L8.9 Series Engines

- L8.9

- L8.9 L121

- L8.9G CMOH2.0 L125B

QSL9 Series Engines

- QSL9 CM850 (CM2850)

This dipstick is engineered to ensure compatibility with the specified engines, providing reliable and accurate oil level readings. It is essential to use the correct dipstick for your engine to maintain optimal engine performance and longevity.

Role of Part 5260645 Dipstick in Engine Systems

The part 5260645 dipstick is an essential component in the accurate measurement and monitoring of oil levels within an engine system. It interfaces directly with the oil level gauge, ensuring that the system provides precise readings of the engine’s oil status.

When the dipstick is inserted into the engine’s oil filler tube, it comes into contact with the oil. The oil adheres to the dipstick, and upon removal, the level of oil on the dipstick can be observed against marked gradients. This direct interaction allows the oil level gauge to offer a visual or mechanical indication of the current oil level within the engine.

The dipstick also plays a role in the ventilation of the crankcase. As it is withdrawn, it allows pressurized gases to escape, which helps maintain a stable pressure environment within the engine. This function is important for the overall health and efficiency of the engine, as it prevents the buildup of harmful gases that could lead to engine wear or failure 3.

Furthermore, the dipstick’s design may include features such as a temperature sensing bulb at the end, which can provide additional data to the engine’s management system, contributing to more informed decision-making regarding engine operation and maintenance.

Conclusion

The Cummins 5260645 Dipstick is a critical component for maintaining the health and efficiency of commercial truck engines. Its accurate measurement of oil levels ensures proper lubrication, which is essential for reducing friction, dissipating heat, and removing contaminants. Regular maintenance and proper use of this part contribute to the longevity and performance of the engine. By understanding its features, benefits, and proper installation and maintenance procedures, technicians can ensure that their engines operate at peak efficiency.

-

Andrew Brown Jr, Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, National Academy of Sciences, 2010.

↩ -

Hamid Taghavifar and Aref Mardani, Offroad Vehicle Dynamics Analysis Modelling and Optimization, Springer, 2017.

↩ -

Matthew Harrison, Controlling Noise and Vibration in Road Vehicles, SAE International, 2004.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.