This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 5268175 Dipstick is a specialized component designed for use in commercial trucks equipped with Cummins engines. Its purpose is to facilitate the monitoring of engine oil levels, ensuring that the engine operates within optimal lubrication parameters. This part is significant in the operation of commercial trucks as it provides a straightforward and reliable method for mechanics and operators to check oil levels, which is vital for maintaining engine health and performance 1.

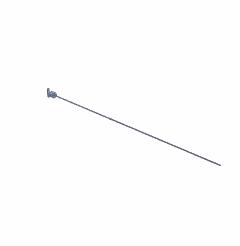

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of lubricant within the engine’s oil sump. It consists of a long, slender rod with a handle at one end, typically made from metal or plastic. The rod is inserted into the engine’s oil fill tube, and when removed, the oil level can be read from markings on the dipstick. This process allows for the assessment of whether the oil level is within the manufacturer’s specified range, ensuring that the engine remains properly lubricated 2.

Purpose of the Cummins 5268175 Dipstick

This Cummins part plays a specific role in the operation of a truck by serving as a direct interface for checking the engine oil level. In the engine’s lubrication system, maintaining the correct oil level is paramount for reducing friction between moving parts, dissipating heat, and carrying away contaminants. The dipstick allows for periodic checks to ensure that the oil level is adequate, thereby contributing to the engine’s efficiency, longevity, and overall performance 3.

Key Features

The Cummins 5268175 Dipstick is characterized by several key features that enhance its performance and durability. It is designed with precision to fit snugly into the oil fill tube of Cummins engines, ensuring accurate readings. The dipstick is constructed from high-quality materials that resist corrosion and wear, ensuring longevity even in the demanding environment of a commercial truck engine. Additionally, it features clear, easy-to-read markings for oil level indication, facilitating quick and accurate assessments by mechanics and operators.

Benefits

Utilizing the Cummins 5268175 Dipstick offers several benefits. It contributes to improved engine performance by ensuring that the engine operates with the correct oil level, which is crucial for optimal lubrication. The dipstick’s durable construction and precise design enhance its longevity, reducing the need for frequent replacements. Moreover, its ease of use makes it a valuable tool for both experienced mechanics and truck operators, simplifying the process of checking engine oil levels.

Installation and Usage

Proper installation and usage of the Cummins 5268175 Dipstick involve a few straightforward steps. First, ensure the engine is turned off and has had sufficient time to cool down to avoid burns from hot oil. Then, locate the oil fill tube on the engine and remove the dipstick by pulling it straight out. Wipe the dipstick clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level against the markings. It’s important to follow these steps carefully to obtain an accurate reading and to avoid contamination of the oil.

Troubleshooting and Maintenance

Common issues with dipsticks may include difficulty in reading the oil level due to wear or contamination. Regular cleaning of the dipstick with a lint-free cloth can help maintain its accuracy. If the dipstick shows signs of significant wear or corrosion, it may be advisable to replace it to ensure reliable oil level readings. Maintenance of the dipstick is straightforward, primarily involving regular cleaning and inspection for damage.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s commitment to advancing technology and improving efficiency is evident in its wide range of products, including the Cummins 5268175 Dipstick, which exemplifies Cummins’ dedication to enhancing the performance and reliability of commercial vehicles.

Cummins Engine Dipstick Compatibility

The Cummins part number 5268175, a Dipstick, is compatible with several models within the Cummins engine lineup. Here’s a breakdown of its compatibility across different engine series:

ISB Series

- ISB CM2150

- ISB/ISD6.7 CM2150 SN

- ISB6.7 CM2250

- ISB6.7 CM2350 B101

- ISB6.7 G CM2180 B118

The dipstick part number 5268175 is designed to fit seamlessly with the ISB series engines, ensuring accurate oil level readings and maintenance. These engines are known for their robust performance and reliability, making them a popular choice in various applications.

ISBE Series

- ISBE CM2150

- ISBE4 CM850

Similar to the ISB series, the ISBE series engines also utilize the Cummins dipstick part number 5268175. This compatibility ensures that users can maintain their engines with ease, regardless of the specific model within the ISBE series. The ISBE engines are engineered for high efficiency and durability, making them suitable for demanding environments.

By ensuring that the dipstick part number 5268175 is compatible with these specific engine models, Cummins maintains a high standard of quality and reliability across its engine lineup. This compatibility allows for straightforward maintenance procedures, contributing to the overall performance and longevity of the engines.

Role of Part 5268175 Dipstick in Engine Systems

The part 5268175 Dipstick is an integral component in the engine system, working in conjunction with several other parts to ensure the engine operates efficiently and safely.

Interaction with the Oil Level Gauge

The dipstick interfaces directly with the oil level gauge, providing a physical means to measure the oil level within the engine. When the dipstick is inserted into the engine, it comes into contact with the oil, allowing the user to visually assess the oil level by withdrawing the dipstick and observing the oil mark. This interaction is essential for maintaining the correct oil level, which is vital for lubricating moving parts, cooling the engine, and cleaning internal components.

Ensuring Accurate Oil Level Readings

Accurate readings from the dipstick are paramount for the proper functioning of the oil level gauge. The dipstick’s design ensures that it provides a consistent and reliable measurement, which the gauge then translates into a readable format for the user. This process helps in preventing both overfilling and underfilling of oil, conditions that can lead to engine damage or reduced performance.

Integration with Engine Components

Within the engine system, the dipstick is typically connected to the oil pan, where the engine oil is stored. Its placement allows for easy access during maintenance checks, enabling quick assessments of the oil condition and level. The dipstick tube, which houses the dipstick, is engineered to seal effectively, preventing oil leaks and ensuring that the oil remains contained within the system.

Supporting Engine Health

By facilitating regular checks of the oil level and condition, the dipstick plays a supportive role in maintaining engine health. It allows for the early detection of issues such as oil contamination, low oil levels, or leaks, enabling timely interventions that can prevent more severe engine problems.

Conclusion

In summary, the part 5268175 Dipstick is a key component in the engine system, working alongside the oil level gauge and other engine components to ensure optimal engine performance and longevity. Its role in facilitating accurate oil level readings, integrating with engine components, and supporting engine health underscores its importance in the maintenance and operation of Cummins engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.