This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

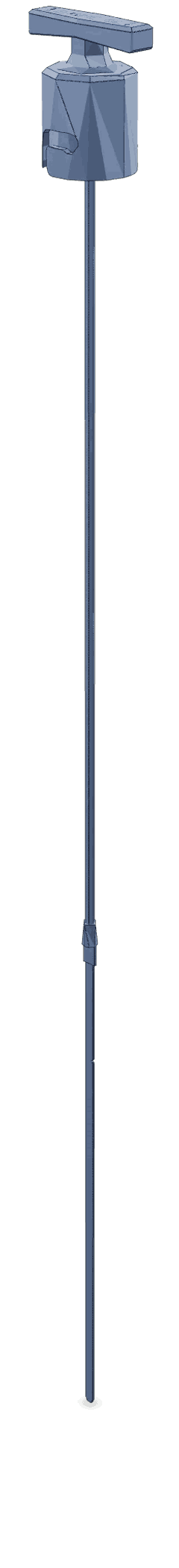

The Cummins 5295411 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the monitoring of oil levels within the engine, ensuring that the engine operates within optimal parameters. This part is significant in the maintenance regimen of heavy-duty trucks, as it allows for precise and reliable oil level checks, which are vital for the longevity and performance of the engine 1.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in engines to measure the level of fluid, typically oil. It consists of a long, thin metal or plastic rod with a handle at one end. The rod is inserted into a tube connected to the sump or reservoir of the engine. Once inserted and then removed, the dipstick displays the fluid level by means of markings along its length. This process allows for quick and easy assessment of whether the fluid level is within the required range 2.

Purpose of the Cummins 5295411 Dipstick

The Cummins 5295411 Dipstick plays a specific role in the operation and maintenance of heavy-duty trucks by providing an accurate means to check oil levels. Proper oil levels are necessary for lubricating engine components, reducing friction, and preventing overheating. By using this dipstick, technicians can ensure that the engine has the correct amount of oil, thereby promoting efficient operation and extending the engine’s lifespan.

Key Features

The Cummins 5295411 Dipstick is characterized by several key features that enhance its functionality. It is crafted from durable materials to withstand the harsh conditions typical of heavy-duty truck environments. The design includes clear and precise markings for easy reading of oil levels. Additionally, the dipstick may feature a robust handle for secure grip during use, ensuring accurate and safe operation.

Benefits of Using the Cummins 5295411 Dipstick

Utilizing the Cummins 5295411 Dipstick offers several advantages. Its design ensures accuracy in fluid level measurement, which is critical for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to wear and corrosion. Furthermore, the dipstick is designed for ease of use, allowing for quick and straightforward oil level checks during routine maintenance.

Installation and Usage

Proper installation and usage of the Cummins 5295411 Dipstick involve a few straightforward steps. First, ensure the engine is turned off and has had sufficient time to cool. Locate the dipstick tube, usually found near the engine’s sump. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then remove it again to check the oil level against the markings. This process should be performed according to the manufacturer’s guidelines to ensure accurate readings.

Maintenance and Care

To ensure the longevity and reliable performance of the Cummins 5295411 Dipstick, regular maintenance and care are recommended. This includes cleaning the dipstick after each use to remove any oil residue and inspecting it for signs of wear or damage. If the dipstick becomes bent or shows significant wear, it should be replaced to maintain accurate oil level readings.

Troubleshooting Common Issues

Common issues with dipsticks, including the Cummins 5295411 model, may involve inaccurate readings due to contamination or damage. If inconsistent oil level readings are observed, the dipstick should be cleaned thoroughly or inspected for damage. In cases where the dipstick appears bent or corroded, replacement is advised to ensure reliable operation.

Safety Considerations

When using the Cummins 5295411 Dipstick, it is important to observe certain safety practices. Always ensure the engine is cool before attempting to check the oil level to avoid burns from hot surfaces or fluids. Handle the dipstick carefully to prevent injury, and follow all safety guidelines provided by the vehicle manufacturer to ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is renowned for its commitment to quality, innovation, and customer satisfaction, providing solutions that meet the demanding requirements of heavy-duty applications.

Cummins Dipstick Part 5295411 Compatibility with ISC Engines

The Cummins dipstick part number 5295411 is designed to fit seamlessly with several ISC engine models, ensuring accurate oil level readings and maintenance. This dipstick is compatible with the following engines:

- ISC CM2150

- ISC CM850

- ISC8.3 CM2250

These engines are part of the ISC series, which is known for its reliability and performance in various applications. The dipstick is engineered to provide a precise measurement of the oil level, facilitating routine maintenance checks and ensuring the engine operates at optimal levels.

For the ISC CM2150 and ISC CM850, the dipstick ensures that users can easily monitor the oil levels, which is crucial for maintaining engine health and preventing potential damage from low oil levels.

The ISC8.3 CM2250 also benefits from the use of this dipstick, providing the same level of accuracy and ease of use. This compatibility across different engine models within the ISC series highlights the dipstick’s versatility and importance in engine maintenance.

Role of Part 5295411 Dipstick in Engine Systems

The part 5295411 dipstick is an essential component in the maintenance and operation of engine systems. It works in conjunction with several other components to ensure the engine operates efficiently and reliably.

Interaction with the Oil Level

The primary function of the dipstick is to provide a means of checking the oil level within the engine. When inserted into the oil filler tube, the dipstick allows mechanics and engineers to visually assess the amount of oil present. This is vital for maintaining the correct oil level, which is necessary for lubricating moving parts, reducing friction, and preventing wear and tear on engine components.

Connection to the Gauge

In some engine systems, the dipstick may be connected to an oil level gauge. This gauge provides a more precise reading of the oil level, often through electronic sensors that detect the oil’s height on the dipstick. The information from the gauge can be displayed on the vehicle’s dashboard, allowing for real-time monitoring of the oil level. This setup enhances the accuracy of oil level readings and enables timely interventions if the oil level falls below the recommended range.

Ensuring Engine Health

By regularly using the dipstick to check the oil level, engineers and mechanics can ensure that the engine remains well-lubricated. Proper lubrication is key to the longevity and performance of the engine. It helps in cooling the engine, cleaning internal components by carrying away contaminants, and maintaining optimal pressure within the engine system.

Facilitating Maintenance

The dipstick also plays a role in facilitating routine maintenance. When the oil level is checked, it is often an opportunity to inspect the oil’s condition. The color and consistency of the oil can indicate whether it needs to be changed. This proactive approach to maintenance helps in identifying potential issues before they become significant problems, thereby enhancing the overall reliability of the engine.

Conclusion

In summary, the Cummins 5295411 Dipstick is a fundamental component in the engine system, working alongside the oil level and gauge to ensure the engine operates smoothly and efficiently. Its role in maintaining proper oil levels is crucial for the longevity and performance of heavy-duty truck engines. Regular use and maintenance of this part contribute significantly to the overall health and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.