This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

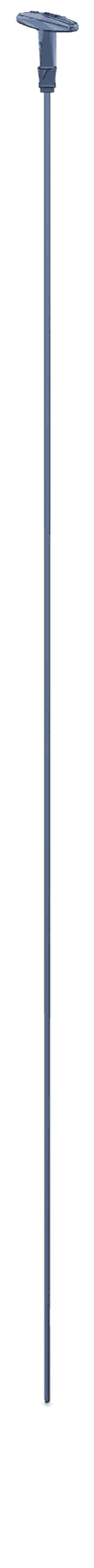

The Cummins 5318114 Dipstick is a specialized component designed for use in heavy-duty trucks. Its purpose is to facilitate the measurement of oil levels within the engine, ensuring that the lubrication system operates effectively. This part is significant in the context of heavy-duty truck maintenance as it provides a straightforward yet vital means of monitoring engine health and performance.

Basic Concepts of a Dipstick

A dipstick is a simple yet essential tool used in internal combustion engines to measure the level of oil. It consists of a long, thin metal or plastic rod with a handle at one end. The other end is inserted into the engine’s oil sump. The dipstick functions by allowing the user to withdraw it and observe the oil level marked on the rod. This process helps in assessing whether the oil level is within the acceptable range, thereby ensuring the engine receives adequate lubrication 1.

Purpose of the Cummins 5318114 Dipstick

This Cummins part plays a role in the operation of a truck by enabling the measurement of oil levels within the engine. Proper lubrication is vital for the engine’s moving parts, reducing friction and wear. By providing an accurate reading of the oil level, this dipstick helps ensure that the engine maintains optimal lubrication, which is fundamental for its efficient and prolonged operation 2.

Key Features

The 5318114 is characterized by its robust design and the materials used in its construction. Typically made from high-quality steel, it is resistant to the high temperatures and pressures found within an engine. Its design may include a curved tip to ensure it fits snugly into the oil sump, and markings for easy reading of the oil level. These features enhance its performance and reliability in demanding environments.

Benefits of Using the Cummins 5318114 Dipstick

Using this part offers several advantages. Its design ensures accuracy in oil level measurement, which is crucial for maintaining engine health. The materials used in its construction contribute to its durability, making it resistant to wear and corrosion. Additionally, its straightforward design makes it easy to use, allowing for quick and reliable oil level checks.

Installation and Usage

To install and use the 5318114, first, ensure the truck is on a level surface and the engine is off. Locate the dipstick tube, usually found near the engine’s center. Pull out the dipstick, wipe it clean with a lint-free cloth, reinsert it fully, and then withdraw it again to check the oil level. For an accurate reading, ensure the dipstick is read at eye level and that the truck is on a level surface.

Troubleshooting Common Issues

Common issues with dipsticks may include inaccurate readings or physical damage. Inaccurate readings can often be resolved by ensuring the dipstick is fully seated in its tube and read correctly. Physical damage, such as bends or cracks, may require replacement of the dipstick to ensure accurate measurements and prevent oil leaks.

Maintenance Tips

To maintain the 5318114, regularly clean it with a lint-free cloth before and after each use to remove any oil residue and contaminants. Inspect it for signs of wear or damage, such as bends or cracks, and replace it if necessary. Keeping the dipstick and its tube clean and free of debris will help ensure accurate oil level readings and prolong the dipstick’s lifespan.

Role in Preventive Maintenance

Regular use of the 5318114 is a key component of preventive maintenance for heavy-duty trucks. By routinely checking the oil level, operators can ensure the engine remains properly lubricated, which helps prevent wear, reduce the risk of engine damage, and maintain overall performance. This practice is a simple yet effective way to contribute to the longevity and reliability of the vehicle.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. Their product range includes a variety of parts and systems designed to enhance the performance, efficiency, and reliability of vehicles.

Cummins Dipstick 5318114 Compatibility with Engine Models

The Cummins dipstick part number 5318114 is designed to be compatible with several engine models, ensuring accurate oil level readings and maintenance. This dipstick is engineered to fit seamlessly with the following Cummins engine series:

ISL9 CM2150 SN and ISL9.5 CM2880 L138

The dipstick 5318114 is specifically tailored for the ISL9 CM2150 SN and ISL9.5 CM2880 L138 engines. These engines are known for their robust performance and reliability in various applications, from heavy-duty trucks to industrial machinery. The dipstick’s design ensures it can easily access the oil pan, providing a clear and accurate reading of the oil level. This compatibility is crucial for maintaining optimal engine performance and preventing potential damage due to low oil levels.

L8.9

The Cummins dipstick 5318114 is also compatible with the L8.9 engine. This engine is widely used in a range of applications, including construction equipment and agricultural machinery. The dipstick’s design allows for easy insertion into the oil pan, ensuring that users can quickly and accurately check the oil level. This feature is essential for maintaining the engine’s health and ensuring it operates efficiently.

Ensuring Compatibility and Performance

When using the Cummins dipstick 5318114 with the aforementioned engines, it is important to ensure that the dipstick is correctly installed and used according to the manufacturer’s guidelines. Proper installation and usage will help maintain the engine’s performance and longevity. Regular checks using this dipstick can prevent issues such as engine overheating, reduced efficiency, and potential engine failure.

Role of Part 5318114 Dipstick in Engine Systems

The part 5318114 Dipstick is a component in the oil level gauge system of an engine. It functions as a measuring tool to determine the quantity of oil within the engine’s crankcase. This part is inserted into the oil filler neck, allowing for a precise reading of the oil level.

When the dipstick is removed and wiped clean, then reinserted and pulled out again, the oil level can be read against the markings on the dipstick. This reading is vital for maintaining the correct oil level, which is necessary for the proper lubrication of engine components such as the crankshaft, camshaft, pistons, and bearings.

In addition to its primary function, the dipstick also serves as a vent for the crankcase, allowing pressure to be released and preventing a vacuum from forming when the oil is consumed or leaked. This venting function is important for the overall health of the engine, as it helps to maintain a stable environment within the crankcase.

The dipstick is also connected to the oil level sensor in some engine systems, which provides an electronic reading of the oil level to the vehicle’s onboard computer. This sensor can trigger a low oil level warning light on the dashboard, alerting the driver to potential issues before they become severe.

Conclusion

In summary, the part 5318114 Dipstick is a multifaceted component that not only aids in the manual assessment of oil levels but also plays a role in the engine’s pressure management and can be integral to the operation of oil level sensors in modern engine systems. Regular use and maintenance of this part are crucial for ensuring the longevity and reliability of heavy-duty truck engines.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.