This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

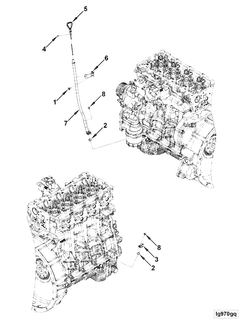

The Cummins 5332214 Dipstick is a specialized component designed for use in heavy-duty trucks. Its primary function is to facilitate the monitoring of engine oil levels, ensuring that the engine operates within optimal lubrication parameters. This part is integral to maintaining the health and efficiency of the engine, contributing to the overall performance and longevity of the vehicle.

Basic Concepts of a Dipstick

A dipstick is a simple yet vital tool used in engine maintenance. It consists of a long, slender rod with a handle at one end, typically made from metal or plastic. The rod is inserted into the engine’s oil reservoir, and when withdrawn, it provides a visual indication of the oil level. This process allows for regular checks to ensure that the engine has sufficient lubrication, which is crucial for its operation and longevity 1.

Purpose of the Cummins 5332214 Dipstick

This Cummins part plays a specific role in monitoring engine oil levels. By providing accurate readings, it helps ensure that the engine maintains proper lubrication. This is particularly important in heavy-duty trucks, where engines operate under significant stress and require consistent lubrication to function efficiently and avoid damage 2.

Key Features

The Cummins 5332214 Dipstick is designed with several key features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions within an engine. The dipstick is also engineered with precise markings that allow for accurate oil level readings. Additionally, its design ensures easy insertion and removal, facilitating regular maintenance checks.

Benefits of Using the Cummins 5332214 Dipstick

Using this part offers several advantages. Its accurate measurement capabilities ensure that engine oil levels are consistently monitored, reducing the risk of engine damage due to insufficient lubrication. The dipstick’s durable construction contributes to its longevity, making it a reliable component for regular use. Furthermore, its ease of use simplifies the maintenance process, allowing for quick and efficient oil level checks.

Installation Process

Installing the Cummins 5332214 Dipstick involves a straightforward process. Begin by ensuring the engine is turned off and has cooled down to avoid burns. Locate the oil filler cap on the engine and remove it. Insert the dipstick fully into the tube until it reaches the bottom, then withdraw it slowly. Check the oil level against the markings on the dipstick. If necessary, add oil to reach the appropriate level. Replace the oil filler cap securely once the correct oil level is achieved.

Maintenance Tips

To ensure the longevity and accuracy of the Cummins 5332214 Dipstick, regular maintenance is recommended. After each use, wipe the dipstick clean with a lint-free cloth to remove any oil residue. Inspect the dipstick for any signs of damage or wear, such as bends or cracks, and replace it if necessary. Keeping the dipstick clean and in good condition will help maintain accurate oil level readings and ensure the engine remains properly lubricated.

Troubleshooting Common Issues

Common issues with dipsticks include inaccurate readings and physical damage. Inaccurate readings may be due to a bent dipstick or incorrect insertion. Ensure the dipstick is straight and fully inserted to obtain accurate readings. Physical damage, such as cracks or bends, can affect the dipstick’s performance. Inspect the dipstick regularly and replace it if any damage is detected to maintain engine health.

Role in Preventive Maintenance

Regular use of the Cummins 5332214 Dipstick is a key component of preventive maintenance practices in fleet operations. By consistently monitoring engine oil levels, fleet managers can identify potential issues before they lead to significant problems. This proactive approach helps maintain engine efficiency, reduces the risk of unexpected breakdowns, and contributes to the overall reliability of the fleet 3.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 5332214 Dipstick, which is designed to meet the demanding requirements of heavy-duty truck engines.

Cummins Dipstick Part 5332214 Compatibility

The Cummins Dipstick part number 5332214 is designed to be compatible with a range of Cummins engines, ensuring accurate and reliable oil level checks. This dipstick is engineered to fit seamlessly into the specified engine models, providing essential functionality for maintenance and operational checks.

Engine Compatibility

- ISF2.8 CM2220 F129

This dipstick is specifically tailored to integrate with the ISF2.8 CM2220 F129 engine, ensuring that users can easily monitor the oil levels without any compatibility issues. The design of the dipstick aligns with the engine’s specifications, allowing for precise readings and facilitating routine maintenance.

Conclusion

The Cummins 5332214 Dipstick is a vital component for maintaining the health and efficiency of heavy-duty truck engines. Its accurate measurement capabilities, durable construction, and ease of use make it an essential tool for regular maintenance checks. By ensuring proper lubrication, this part contributes to the overall performance and longevity of the vehicle, supporting preventive maintenance practices and enhancing fleet reliability.

-

Vaclav Smil, The History and Impact of Diesel Engines and Gas Turbines, The MIT Press, 2010.

↩ -

Dominique Bonneau, Aurelian Fatu, and Dominique Souchet, Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings, Wiley-ISTE, 2014.

↩ -

Amir Khajepour, Synthesis Lectures on Advances in Automotive Technology, Springer, 2023.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.