This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

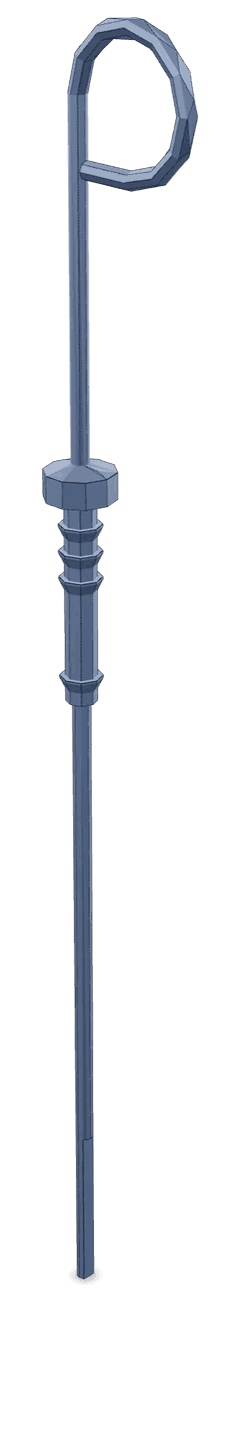

Engine maintenance is crucial for the operational efficiency and longevity of commercial trucks. Regular upkeep ensures these vehicles perform at peak levels, minimizing downtime and maximizing productivity. Cummins, a leader in engine manufacturing, provides high-quality components designed to enhance engine performance and durability. This article explores the Cummins C6204215310 dipstick, a vital component in the maintenance of Cummins engines, detailing its function, integration within the engine system, and the importance of its maintenance.

Basic Concepts Related To Dipsticks

A dipstick is a fundamental tool in engine maintenance, used to check the oil level within an engine. It operates by inserting a long, slender rod into the engine’s oil reservoir. Upon removal, the oil level can be gauged by observing the oil on the dipstick. Regular oil level checks are essential for engine health, ensuring adequate lubrication to prevent excessive wear, overheating, and potential engine failure 1.

The Role Of The Cummins C6204215310 Dipstick

The Cummins C6204215310 dipstick is engineered for use in Cummins engines, playing a crucial role in the engine’s oil system. It is designed to integrate seamlessly with the engine, allowing for precise oil level measurements essential for maintaining optimal engine performance. Accurate readings from this part are critical for ensuring the engine operates within safe parameters, highlighting its significance in the overall engine maintenance strategy 2.

Troubleshooting And Maintenance

Despite its simplicity, the C6204215310 dipstick can encounter issues affecting its accuracy and functionality. Common problems include oil contamination leading to inaccurate readings and physical damage to the dipstick. To ensure accurate oil level checks, follow a step-by-step process: remove the dipstick, wipe it clean, reinsert it fully, remove it again, and then check the oil level against the markers on the dipstick. Regular maintenance, such as cleaning the dipstick and its tube, can prolong its life and ensure reliable readings. Should the dipstick indicate abnormal oil levels, further investigation is crucial, as this could signal underlying issues such as oil leaks or consumption 3.

Cummins’ Commitment To Quality

Cummins’ reputation for quality is built on rigorous quality control processes that ensure every component, including the C6204215310 dipstick, meets the highest standards of reliability and performance. The company’s commitment to innovation and reliability is evident in its manufacturing approach, where each part is designed to meet and exceed industry standards. Utilizing Cummins parts, such as the C6204215310 dipstick, significantly enhances the overall reliability and performance of commercial trucks, underscoring the value of investing in quality components.

Expert Insights On Dipstick Maintenance

Industry experts emphasize the critical role of dipstick maintenance in preventing major engine failures. Integrating dipstick checks into routine engine maintenance schedules is a best practice that can save fleets from costly repairs and downtime. The dipstick serves as an early warning system, alerting mechanics and engineers to potential issues before they escalate. By prioritizing dipstick maintenance, fleets can ensure their engines remain in optimal condition, thereby extending the lifespan of their commercial trucks.

Conclusion

The Cummins C6204215310 dipstick is a testament to the importance of even the simplest components in ensuring the reliability and performance of commercial truck engines. Its role in facilitating accurate oil level checks cannot be overstated, making it a critical element in the maintenance regimen of Cummins engines. Engineers, mechanics, and fleet operators are encouraged to prioritize dipstick maintenance as part of their routine engine care, leveraging the quality and reliability of Cummins components to enhance their fleet’s performance and longevity. For those seeking further knowledge on commercial truck parts and maintenance, Cummins offers a wealth of resources to explore.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.