This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

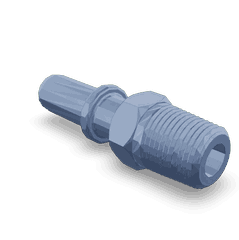

The Cummins 3696781 Quick Disconnect Connector is a specialized component designed for use in commercial trucks. It facilitates the efficient and safe transfer of fluids within the vehicle’s systems. This connector is integral to maintaining the operational integrity of the truck, ensuring that fluid transfer processes are both rapid and secure.

Basic Concepts of Quick Disconnect Connectors

Quick disconnect connectors are devices used in automotive and industrial applications to allow for the swift and secure connection and disconnection of fluid lines. They are commonly employed in systems requiring frequent coupling and decoupling, such as refueling, hydraulic systems, and pneumatic applications. These connectors are engineered to minimize leaks and ensure a tight seal when connected, while allowing for easy separation when needed 1.

Purpose of the Cummins 3696781 Quick Disconnect Connector

The Cummins 3696781 Quick Disconnect Connector is specifically designed to play a role in the fluid transfer systems of commercial trucks. It enables the quick and secure connection and disconnection of fluid lines, which is particularly useful during maintenance procedures or when switching between different fluid systems. This connector ensures that the transfer of fluids is conducted with minimal risk of spillage or leakage, thereby enhancing both safety and efficiency 2.

Key Features

The Cummins 3696781 Quick Disconnect Connector boasts several key features that enhance its functionality. It is constructed from durable materials to withstand the rigors of commercial truck operations. The design incorporates a robust connection mechanism that ensures a secure seal when engaged. Additionally, it features an easy-to-use release mechanism that allows for quick disconnection without the need for specialized tools 3.

Benefits

The Cummins 3696781 Quick Disconnect Connector offers several advantages. It simplifies the process of connecting and disconnecting fluid lines, reducing the time required for maintenance tasks. This connector also helps to minimize leaks, which can be a common issue with traditional coupling methods. Furthermore, it enhances safety by providing a secure connection that reduces the risk of fluid spills during operation 4.

Installation Process

Installing the Cummins 3696781 Quick Disconnect Connector involves several steps to ensure proper function and safety. First, ensure that the fluid lines are clean and free of debris. Next, align the connector with the mating component and press firmly until a secure connection is achieved. It is important to follow any manufacturer-specified torque settings to ensure the connection is tight. Safety precautions, such as wearing protective gloves and eyewear, should be observed during installation.

Troubleshooting Common Issues

Common issues with quick disconnect connectors include leaks and faulty connections. To address these problems, first, ensure that the connector is properly aligned and seated. If a leak is detected, inspect the O-rings and gaskets for wear or damage and replace them if necessary. Additionally, check for any obstructions in the fluid lines that may be preventing a secure connection.

Maintenance Tips

Regular maintenance of the Cummins 3696781 Quick Disconnect Connector is important to ensure its longevity and reliable performance. This includes routine cleaning of the connector and inspection of the O-rings and gaskets for signs of wear. It is also advisable to periodically test the connection for leaks and ensure that the release mechanism functions correctly. If any components show signs of significant wear, they should be replaced to maintain the integrity of the fluid transfer system.

Safety Considerations

When working with quick disconnect connectors, it is important to follow safety practices to prevent accidents and ensure efficient operation. This includes handling the connectors with care to avoid damage, ensuring that connections are secure before operating the system, and being aware of system pressures to prevent injuries from sudden releases.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes components and systems designed to enhance the performance, efficiency, and reliability of commercial vehicles.

Quick Disconnect Connector 3696781 Compatibility with Cummins Engines

The Quick Disconnect Connector 3696781, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engines. This connector is a crucial component for ensuring efficient and reliable operation across different engine models. Here’s a detailed look at its compatibility with specific engine types:

ISG11 CM2880 G108 and ISG12 CM2880 G107

The ISG11 CM2880 G108 and ISG12 CM2880 G107 engines are part of Cummins’ range of industrial and stationary gas engines. These engines are known for their robust performance and reliability in demanding applications. The Quick Disconnect Connector 3696781 is engineered to interface with these engines, facilitating easy connection and disconnection of fuel lines, hydraulic lines, or other fluid systems. This ensures that maintenance and servicing can be performed swiftly and efficiently.

ISG12 G CMOH6.0 G111

The ISG12 G CMOH6.0 G111 engine is another variant within Cummins’ industrial gas engine lineup. This model is designed for high-performance applications, often used in power generation and industrial processes. The Quick Disconnect Connector 3696781 is compatible with this engine, providing a reliable connection mechanism that can withstand the rigors of continuous operation. This compatibility ensures that the engine can be serviced without the need for complex and time-consuming procedures.

QSG12/X12 CM2350 G110

The QSG12/X12 CM2350 G110 engine is a part of Cummins’ range of medium-duty gas engines. These engines are often used in a variety of applications, including agricultural and industrial settings. The Quick Disconnect Connector 3696781 is designed to fit this engine, providing a quick and easy way to connect and disconnect various fluid lines. This feature is particularly beneficial in environments where frequent maintenance and servicing are required.

X11 CM2670 X126B and X12 CM2670 X121B

The X11 CM2670 X126B and X12 CM2670 X121B engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their durability and efficiency, making them suitable for a wide range of applications. The Quick Disconnect Connector 3696781 is compatible with these engines, providing a reliable connection mechanism for fuel and hydraulic lines. This ensures that maintenance and servicing can be performed quickly and efficiently, minimizing downtime.

X12N CMMDG1 X143B and X13 CM2670 X122B

The X12N CMMDG1 X143B and X13 CM2670 X122B engines are part of Cummins’ range of medium-duty diesel engines. These engines are designed for high-performance applications, often used in construction and agricultural equipment. The Quick Disconnect Connector 3696781 is engineered to fit these engines, providing a reliable and efficient connection mechanism for various fluid lines. This compatibility ensures that the engines can be serviced swiftly, reducing the time required for maintenance and repairs.

Role of Part 3696781 Quick Disconnect Connector in Engine Systems

The Part 3696781 Quick Disconnect Connector is an essential component in the efficient operation of various engine systems, particularly those involving the compressor and air management.

Compressor Systems

In compressor systems, the Quick Disconnect Connector facilitates the seamless connection and disconnection of air lines. This allows for easier maintenance and servicing of the compressor without the need for complex disassembly. The connector ensures a secure and leak-free seal when in use, maintaining the integrity of the compressed air system. It also enables quick changes or upgrades to the compressor setup, enhancing operational flexibility.

Air Management Systems

For air management systems, the Quick Disconnect Connector plays a significant role in regulating and directing airflow. It allows for the rapid connection and disconnection of air hoses and fittings, which is particularly useful in environments where equipment needs frequent reconfiguration. The connector helps in maintaining consistent air pressure and flow, which is vital for the performance of pneumatic tools and machinery.

Integration with Other Components

The Quick Disconnect Connector also integrates well with other components such as filters, regulators, and lubricators. By providing a reliable connection point, it ensures that these components can be quickly attached or detached as needed. This is especially beneficial in industrial settings where downtime needs to be minimized. The connector’s design allows for easy inspection and maintenance of the air lines, contributing to the overall reliability and efficiency of the engine system.

Conclusion

The Cummins 3696781 Quick Disconnect Connector is a versatile and reliable component that enhances the efficiency and safety of fluid transfer systems in commercial trucks. Its compatibility with a wide range of Cummins engines ensures that maintenance and servicing can be performed swiftly and effectively, minimizing downtime and enhancing operational flexibility.

-

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Kluczyk, Barry. How to Rebuild Any Automotive Engine. CarTech, 2008.

↩ -

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.