This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

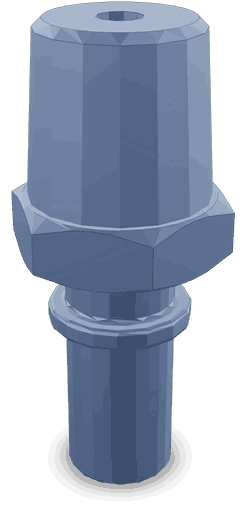

The Cummins 3969652 Quick Disconnect Coupling is a specialized component designed for use in commercial trucks. It facilitates the efficient transfer of fluids, which is integral to the operation of various truck systems. This coupling is significant in enhancing the ease and safety of fluid management in commercial vehicles.

Basic Concepts of Quick Disconnect Couplings

Quick disconnect couplings are mechanisms that allow for the rapid connection and disconnection of fluid lines. They are widely used across multiple industries for their convenience and efficiency. In commercial trucking, these couplings are particularly valuable for their role in simplifying the process of connecting and disconnecting fluid lines, which is a common requirement during maintenance and operations 1.

Purpose of the Cummins 3969652 Quick Disconnect Coupling

This Cummins part is employed in the fluid transfer systems of trucks. It enables the quick and secure connection of fluid lines, which is crucial for the operation of systems such as hydraulics, fuel transfer, and coolant systems. This coupling ensures that fluid transfer is conducted with minimal risk of spills or leaks, enhancing both safety and efficiency 2.

Key Features

The 3969652 is characterized by several key features that contribute to its performance and durability. It is designed with precision to ensure a tight seal, reducing the likelihood of leaks. The coupling is constructed from high-quality materials that resist corrosion and wear, ensuring longevity. Additionally, it features an easy-to-use design that allows for quick connection and disconnection without the need for specialized tools 3.

Benefits

The 3969652 offers several benefits. It enhances operational efficiency by allowing for rapid connection and disconnection of fluid lines. This feature is particularly beneficial during maintenance procedures, reducing downtime. Additionally, the coupling’s design contributes to ease of use, making it accessible for operators with varying levels of technical expertise. Furthermore, its robust construction and resistance to wear contribute to lower maintenance requirements 4.

Installation Process

Installing the 3969652 involves several steps to ensure proper function and safety. First, the fluid lines should be prepared by cleaning and, if necessary, cutting to the appropriate length. The coupling is then attached to the fluid line using the provided fittings. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a secure connection. Once installed, the coupling should be tested for leaks before being put into operation 5.

Troubleshooting Common Issues

Common issues with quick disconnect couplings include leaks, difficulty in disconnection, and corrosion. To address leaks, it is important to inspect the coupling for proper installation and ensure that all connections are tight. If disconnection is difficult, lubrication may be required. Corrosion can be mitigated by regular inspection and cleaning, as well as by ensuring that the coupling is made from corrosion-resistant materials 6.

Maintenance Tips

Regular maintenance of the 3969652 is key to ensuring its reliable performance. This includes periodic inspection for signs of wear or corrosion, cleaning to remove any buildup, and lubrication of moving parts to facilitate easy connection and disconnection. Additionally, it is important to follow the manufacturer’s recommendations for maintenance intervals and procedures 7.

Safety Considerations

When installing, maintaining, or troubleshooting the 3969652, it is important to observe several safety practices. This includes wearing appropriate personal protective equipment, ensuring that the vehicle is securely parked and the engine is off during maintenance procedures, and following all manufacturer guidelines for safe operation and maintenance 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions solutions. With a strong reputation in the commercial trucking industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and history of excellence make it a trusted name in the industry.

Cummins Quick Disconnect Coupling 3969652 Compatibility

The Cummins Quick Disconnect Coupling part number 3969652 is designed to fit a variety of Cummins engines, ensuring seamless integration and reliable performance. This coupling is engineered to provide a secure and efficient connection for various fluid lines, enhancing the operational efficiency of the engines it is paired with.

Compatible Engines

- 4B3.9

- B6.7 CM2670 B153B

- ISB/ISD4.5 CM2150 B119

- ISB/ISD6.7 CM2150 SN

- ISBE CM2150

- ISBE CM800

- ISBE4 CM850

- ISC CM850

- ISL9 CM2150 SN

This coupling is particularly suited for engines that require frequent fluid line connections and disconnections, such as those used in heavy-duty applications where maintenance and operational efficiency are critical. The design of the 3969652 ensures that it can withstand the rigors of these demanding environments, providing a durable and reliable solution for engine maintenance and operation.

Role of Part 3969652 Quick Disconnect Coupling in Engine Systems

The Part 3969652 Quick Disconnect Coupling is an essential component in the efficient operation of various engine systems. It facilitates seamless connections and disconnections in the plumbing arrangements, ensuring that the system can be quickly and safely serviced or modified without the need for complex disassembly.

In the context of the compressor coolant system, the Quick Disconnect Coupling allows for rapid connection and disconnection of the coolant lines. This is particularly beneficial during maintenance or emergency situations where time is of the essence. The coupling ensures a secure seal when connected, preventing coolant leaks and maintaining system integrity.

When integrated with the water inlet system, the coupling enables easy attachment and detachment of water supply lines. This feature is advantageous in scenarios where the water inlet needs to be frequently changed or serviced, such as in testing environments or during routine maintenance checks.

Overall, the Part 3969652 Quick Disconnect Coupling enhances the flexibility and reliability of engine systems by providing a robust and convenient solution for connecting and disconnecting critical components.

Conclusion

The Cummins 3969652 Quick Disconnect Coupling is a vital component in the maintenance and operation of commercial truck engines. Its design and features contribute to enhanced safety, efficiency, and reliability in fluid management systems. Regular maintenance and adherence to safety practices are essential to ensure the optimal performance of this part.

-

Parikyan, T. (Ed.). (2022). Advances in Engine and Powertrain Research and Technology. Springer Nature.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Viskup, R. (2020). Diesel and Gasoline Engines. IntechOpen.

↩ -

Xin, Q. (2011). Diesel Engine System Design. Woodhead Publishing Limited.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326108.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326108.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326108.

↩ -

Cummins Inc. (n.d.). Owners Manual for QSV91-G4 CM558/CM700 V102. Bulletin Number 4326108.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.