This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

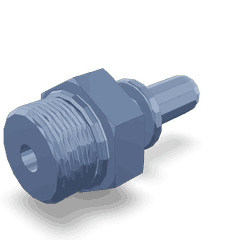

The 5364540 Quick Disconnect Connector, manufactured by Cummins, is designed to facilitate efficient and safe connections in commercial truck operations. Cummins is known for its commitment to quality and innovation, and this part is significant in enhancing the operational efficiency and safety of commercial trucks by providing a reliable connection mechanism for various systems.

Basic Concepts of Quick Disconnect Connectors

Quick disconnect connectors are devices used to join two components rapidly and securely, allowing for easy separation when needed. They are widely utilized in automotive and industrial settings for their convenience and efficiency. These connectors function by using a simple push-to-connect mechanism, which creates a secure seal without the need for additional tools. This design is particularly beneficial in applications where frequent connections and disconnections are required 1.

Purpose of the 5364540 Quick Disconnect Connector

The 5364540 Quick Disconnect Connector is specifically designed for use in commercial trucks. It plays a role in various systems, including fuel systems and hydraulic systems. In fuel systems, it ensures a secure connection between fuel lines, reducing the risk of leaks and enhancing safety. In hydraulic systems, it facilitates quick and reliable connections, which is crucial for the efficient operation of hydraulic components. Additionally, it can be used in other systems where a secure, yet easily detachable, connection is required 2.

Key Features

The 5364540 Quick Disconnect Connector boasts several key features that enhance its performance and reliability. Its design incorporates high-quality materials that are resistant to wear and corrosion, ensuring durability in demanding environments. The connection mechanism is engineered for a secure fit, minimizing the risk of disconnection during operation. Additionally, the connector features a unique design that allows for easy connection and disconnection, reducing the time required for maintenance tasks 3.

Benefits

The use of the 5364540 Quick Disconnect Connector offers several benefits. It simplifies the connection process, making it easier and faster to connect and disconnect components. This ease of use translates to significant time savings during maintenance, allowing for quicker turnaround times. Moreover, the secure connection mechanism reduces the likelihood of leaks, enhancing safety and efficiency. The connector’s design also contributes to improved overall system performance by ensuring a consistent and reliable connection 4.

Installation Process

Installing the 5364540 Quick Disconnect Connector involves a straightforward process. Begin by ensuring the surfaces to be connected are clean and free of debris. Align the connector with the mating component and push firmly until a secure connection is achieved. It is important to follow the manufacturer’s guidelines for proper installation to ensure a secure and effective connection. Using the appropriate tools can facilitate the installation process and ensure the connector is properly seated.

Troubleshooting Common Issues

Common issues with the 5364540 Quick Disconnect Connector may include leaks, difficulty in disconnection, and connection failures. To address leaks, inspect the connector for signs of wear or damage and ensure it is properly seated. If disconnection is difficult, check for obstructions or debris that may be preventing a clean release. Connection failures can often be resolved by ensuring the surfaces are clean and the connector is correctly aligned before pushing to connect.

Maintenance Tips

Regular maintenance of the 5364540 Quick Disconnect Connector is crucial for ensuring its longevity and optimal performance. This includes periodic cleaning to remove any buildup that could affect the connection quality. Inspecting the connector for signs of wear and tear is also important, as this can indicate when a replacement is necessary. Following the manufacturer’s maintenance guidelines will help maintain the connector’s performance and reliability.

Safety Considerations

When working with the 5364540 Quick Disconnect Connector, especially in high-pressure systems, it is important to follow safety guidelines. Ensure that all connections are secure before operating the system to prevent leaks or disconnections. Use personal protective equipment as necessary, and be aware of the system’s pressure ratings to avoid overpressurization. Adhering to these safety considerations will help ensure a safe working environment.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of commercial applications. Cummins’ commitment to quality and innovation is evident in its wide array of products, including the 5364540 Quick Disconnect Connector.

Quick Disconnect Connector 5364540 by Cummins

The Quick Disconnect Connector 5364540, manufactured by Cummins, is a component designed to facilitate the safe and efficient connection and disconnection of hydraulic and fuel lines in various engine applications. This part is engineered to ensure reliable performance and ease of use, making it an essential element in the maintenance and operation of the following Cummins engines:

L8.9 CM2670 L134C

In the L8.9 CM2670 L134C engine, the Quick Disconnect Connector 5364540 is utilized to manage the hydraulic and fuel lines, ensuring that these connections can be made and broken quickly without the need for complex tools or procedures. This feature is particularly beneficial in environments where frequent maintenance or quick servicing is required.

QSC8.3 CM2880 C102 and QSL9.3 CM2880 L113

Similarly, in the QSC8.3 CM2880 C102 and QSL9.3 CM2880 L113 engines, the Quick Disconnect Connector 5364540 plays a pivotal role in managing the hydraulic and fuel lines. Its design allows for rapid and secure connections, which is crucial for maintaining operational efficiency and minimizing downtime during maintenance activities.

The use of the Quick Disconnect Connector 5364540 across these engines underscores its versatility and importance in ensuring that hydraulic and fuel systems can be managed effectively and safely. This part is a testament to Cummins’ commitment to providing reliable and user-friendly solutions for engine maintenance and operation.

Role of Part 5364540 Quick Disconnect Connector in Engine Systems

The Part 5364540 Quick Disconnect Connector is a component in various engine systems, facilitating efficient and secure connections between different parts. Its application is particularly notable in the Compressor Coolant Arrangement and the Plain Adapter Tee.

Compressor Coolant Arrangement

In the Compressor Coolant Arrangement, the Quick Disconnect Connector is used to link the coolant lines to the compressor. This connection allows for the seamless flow of coolant, which is vital for maintaining optimal operating temperatures of the compressor. The quick disconnect feature enables easy maintenance and servicing, allowing technicians to rapidly disconnect the coolant lines without the need for complex tools or procedures. This not only saves time but also reduces the risk of coolant spills and associated hazards.

Plain Adapter Tee

The Plain Adapter Tee is another component where the Quick Disconnect Connector proves invaluable. This tee fitting is often used to merge or split fluid lines within the engine system. By incorporating the Quick Disconnect Connector into the Plain Adapter Tee, engineers and mechanics can quickly attach or detach fluid lines as needed. This is particularly useful during diagnostic procedures or when performing routine maintenance checks. The secure connection ensures that there are no leaks, maintaining the integrity of the fluid system and ensuring consistent performance.

In both applications, the Part 5364540 Quick Disconnect Connector enhances the efficiency and safety of engine maintenance and operation. Its design allows for rapid connections and disconnections, minimizing downtime and facilitating easier access to critical components within the engine system.

Conclusion

The 5364540 Quick Disconnect Connector by Cummins is a vital component in commercial truck operations, offering efficient and secure connections for various systems. Its design and features contribute to enhanced safety, reduced maintenance time, and improved overall system performance. Regular maintenance and adherence to safety guidelines are essential to ensure the longevity and reliability of this Cummins part.

-

Hiereth, H., Prenninger, P., & Drexl, K. W. (2010). Charging the Internal Combustion Engine. Springer.

↩ -

Lejda, K., & Wos, P. (2012). Internal Combustion Engines. InTech.

↩ -

Eret, A. (2024). Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature.

↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.