5318056

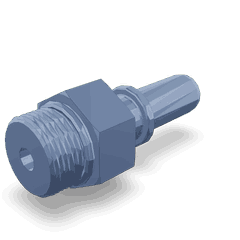

Quick Disconnect Connector

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 5318056 Quick Disconnect Coupling, manufactured by Cummins, is a specialized component designed for use in commercial trucks. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this coupling to enhance the efficiency and reliability of fluid transfer systems in trucks. This part is integral to the seamless operation of various truck systems, ensuring that fluid connections can be made and broken quickly and securely.

Basic Concepts of Quick Disconnect Couplings

Quick disconnect couplings are mechanical devices that allow for the rapid connection and disconnection of fluid lines without the need for tools. They are widely used across various industries, including automotive, aerospace, and manufacturing, for their convenience and efficiency. These couplings typically consist of a male and female component that align and lock into place, creating a secure seal that prevents leaks. They are designed to withstand repeated connections and disconnections, making them ideal for applications where frequent changes are necessary 1.

Purpose of the 5318056 Quick Disconnect Coupling

In the context of commercial trucks, the 5318056 Quick Disconnect Coupling plays a significant role in the fluid transfer systems. It is used to connect and disconnect hoses and pipes that carry fluids such as fuel, coolant, and hydraulic fluid. By providing a quick and secure connection, this part ensures that fluid transfer is efficient and reliable, reducing the risk of leaks and downtime. Its application in trucks is particularly valuable in situations where rapid changes or maintenance checks are required 2.

Key Features

The 5318056 Quick Disconnect Coupling boasts several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring longevity even in harsh operating conditions. The design includes a robust locking mechanism that secures the connection, preventing accidental disconnections. Additionally, the coupling is engineered to provide a tight seal, minimizing the risk of fluid leaks. Its compact and ergonomic design allows for easy handling and installation, further adding to its practicality in commercial truck applications 3.

Benefits

The benefits of using the 5318056 Quick Disconnect Coupling are manifold. Its quick-connect feature significantly reduces the time required for fluid line connections and disconnections, enhancing operational efficiency. The secure locking mechanism ensures that connections remain intact during operation, contributing to the reliability of the fluid transfer system. Furthermore, the coupling’s design promotes ease of use, allowing for straightforward installation and maintenance. These attributes collectively contribute to the overall performance and dependability of commercial trucks.

Installation Process

Installing the 5318056 Quick Disconnect Coupling involves several steps to ensure a proper and secure connection. Begin by preparing the fluid lines to be connected, ensuring they are clean and free of debris. Align the male and female components of the coupling, then press them together until you hear a click, indicating that the locking mechanism has engaged. It is important to verify that the connection is secure by attempting to gently pull the components apart. If the coupling holds firm, the installation is complete. Tools required may include basic hand tools for preparing the fluid lines.

Troubleshooting

Common issues with the 5318056 Quick Disconnect Coupling may include difficulty in connecting or disconnecting, leaks, or a loose connection. To address these problems, first, ensure that the coupling components are clean and free of obstructions. If the coupling is difficult to connect, check for proper alignment and ensure that the locking mechanism is functioning correctly. In the case of leaks, inspect the seal for damage and verify that the connection is secure. If the coupling feels loose, re-engage the locking mechanism or replace the coupling if necessary.

Maintenance Tips

Regular maintenance of the 5318056 Quick Disconnect Coupling is crucial for ensuring its longevity and optimal performance. Inspect the coupling regularly for signs of wear or damage, such as cracks or corrosion. Clean the coupling components periodically to remove any buildup of dirt or debris that could affect the seal. Lubricating the moving parts of the coupling can also help maintain its functionality. Additionally, verify that the locking mechanism is operating correctly and replace any worn-out components as needed.

Safety Considerations

When installing, using, or maintaining the 5318056 Quick Disconnect Coupling, it is important to observe several safety guidelines. Ensure that the fluid lines are depressurized before making or breaking connections to prevent injury from spraying fluid. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow the manufacturer’s instructions for installation and maintenance to ensure safe and effective use of the coupling. Additionally, be mindful of the surrounding environment to avoid accidents or damage to other components.

Compatibility with Cummins Engines

The Quick Disconnect Coupling part number 5318056, manufactured by Cummins, is designed to fit a variety of Cummins engines. This coupling is essential for applications requiring easy and quick connection and disconnection of fuel lines, ensuring operational efficiency and safety.

C GAS PLUS CM556

The C GAS PLUS CM556 engine is compatible with the 5318056 Quick Disconnect Coupling, facilitating seamless connections for fuel lines.

ISB/ISD4.5 CM2150 B119

The ISB/ISD4.5 CM2150 B119 engine utilizes the 5318056 Quick Disconnect Coupling, providing a reliable method for quick and easy fuel line connections.

ISB6.7 CM2250

The ISB6.7 CM2250 engine is designed to work with the 5318056 Quick Disconnect Coupling, ensuring efficient and safe fuel line management.

ISB6.7 CM2350 B101

The ISB6.7 CM2350 B101 engine is compatible with the 5318056 Quick Disconnect Coupling, offering a practical solution for quick fuel line connections.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is designed to fit the 5318056 Quick Disconnect Coupling, providing ease of use for fuel line connections.

ISC CM2150

The ISC CM2150 engine is compatible with the 5318056 Quick Disconnect Coupling, ensuring efficient and safe fuel line connections.

ISC8.3 CM2250

The ISC8.3 CM2250 engine is designed to work with the 5318056 Quick Disconnect Coupling, offering a practical solution for quick fuel line connections.

ISL CM2150

The ISL CM2150 engine is compatible with the 5318056 Quick Disconnect Coupling, facilitating seamless connections for fuel lines.

ISL G CM2180

The ISL G CM2180 engine is designed to fit the 5318056 Quick Disconnect Coupling, providing ease of use for fuel line connections.

ISL9 CM2150 SN

The ISL9 CM2150 SN engine is compatible with the 5318056 Quick Disconnect Coupling, ensuring efficient and safe fuel line connections.

ISL9 CM2250

The ISL9 CM2250 engine is designed to work with the 5318056 Quick Disconnect Coupling, offering a practical solution for quick fuel line connections.

L8.9G CMOH2.0 L125B

The L8.9G CMOH2.0 L125B engine is compatible with the 5318056 Quick Disconnect Coupling, facilitating seamless connections for fuel lines.

L9 CM2670 L128B

The L9 CM2670 L128B engine is designed to fit the 5318056 Quick Disconnect Coupling, providing ease of use for fuel line connections.

QSB6.7 CM2250

The QSB6.7 CM2250 engine is compatible with the 5318056 Quick Disconnect Coupling, ensuring efficient and safe fuel line connections.

QSB6.7 CM2350 B105

The QSB6.7 CM2350 B105 engine is designed to work with the 5318056 Quick Disconnect Coupling, offering a practical solution for quick fuel line connections.

QSB6.7 CM850 (CM2850)

The QSB6.7 CM850 (CM2850) engine is compatible with the 5318056 Quick Disconnect Coupling, facilitating seamless connections for fuel lines.

QSB7 CM2880 B117

The QSB7 CM2880 B117 engine is designed to fit the 5318056 Quick Disconnect Coupling, providing ease of use for fuel line connections.

QSC8.3 CM850 (CM2850)

The QSC8.3 CM850 (CM2850) engine is compatible with the 5318056 Quick Disconnect Coupling, ensuring efficient and safe fuel line connections.

QSC9 CM2250/QSL9 CM2250

The QSC9 CM2250/QSL9 CM2250 engines are designed to work with the 5318056 Quick Disconnect Coupling, offering a practical solution for quick fuel line connections.

QSL9 CM2250

The QSL9 CM2250 engine is compatible with the 5318056 Quick Disconnect Coupling, facilitating seamless connections for fuel lines.

QSL9 CM2350 L102

The QSL9 CM2350 L102 engine is designed to fit the 5318056 Quick Disconnect Coupling, providing ease of use for fuel line connections.

Role of Part 5318056 Quick Disconnect Coupling in Engine Systems

The 5318056 Quick Disconnect Coupling is integral to the efficient operation and maintenance of various engine systems. Its primary function is to facilitate the rapid connection and disconnection of fluid lines, which is essential for both routine maintenance and emergency repairs.

Integration with Air Compressor Systems

In air compressor systems, the Quick Disconnect Coupling allows for the swift attachment and detachment of air lines. This capability is particularly beneficial during maintenance checks or when switching between different air tools. The coupling ensures a secure connection that prevents air leaks, maintaining the efficiency and performance of the air compressor.

Role in Compressor Coolant Arrangements

For compressor coolant arrangements, the Quick Disconnect Coupling is used to connect and disconnect coolant lines efficiently. This is vital for systems that require regular coolant changes or when performing maintenance on the compressor itself. The coupling ensures that the coolant system remains sealed, preventing coolant loss and maintaining optimal cooling performance.

Application in Compressor Coolant Plumbing

In the context of compressor coolant plumbing, the Quick Disconnect Coupling simplifies the process of connecting and disconnecting coolant hoses. This is especially useful in systems where coolant lines need to be accessed frequently for inspection or replacement. The coupling’s design allows for a leak-free connection, ensuring that the coolant system operates efficiently.

Use in Fuel Module Coolant Plumbing

For fuel module coolant plumbing, the Quick Disconnect Coupling plays a significant role in connecting and disconnecting coolant lines to the fuel module. This is important for systems that require regular maintenance or upgrades to the fuel module. The coupling ensures that the connection is secure and leak-free, which is essential for the safe and efficient operation of the fuel system.

Compatibility with Plain Adapter Tee

The Quick Disconnect Coupling is also compatible with plain adapter tees, allowing for the creation of complex fluid distribution networks. This compatibility is particularly useful in systems where multiple fluid lines need to be connected or disconnected simultaneously. The coupling ensures that each connection is secure and maintains the integrity of the fluid system.

Conclusion

Overall, the 5318056 Quick Disconnect Coupling enhances the functionality and maintainability of various engine systems by providing a reliable and efficient means of connecting and disconnecting fluid lines. Its robust design, ease of use, and compatibility with a wide range of Cummins engines make it a valuable component in the maintenance and operation of commercial trucks.

SPECIFICATIONS

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3046201 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.