This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

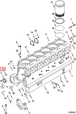

The Diamond Dowel 205366, a component manufactured by Cummins, is integral to the commercial truck industry. This Cummins part contributes to the efficient operation and reliability of commercial vehicles. Understanding its role and functionality is essential for professionals involved in the maintenance and operation of heavy-duty trucks.

Basic Concepts and Functionality

The Diamond Dowel 205366 operates on principles of mechanical alignment and support within a truck’s system. It ensures precise alignment between components, vital for the smooth operation of the vehicle. Crafted from durable materials, typically high-grade steel, it is designed to withstand heavy-duty use. Its design includes specific dimensions and a smooth surface finish to facilitate easy insertion and secure fitment 1.

Purpose and Role in Truck Operation

In truck operation, the Diamond Dowel 205366 maintains alignment between critical components. This alignment is essential for efficient power transfer and reducing wear on moving parts. By ensuring components are correctly positioned, the dowel contributes to the truck’s overall performance and reliability, minimizing mechanical failure risks and enhancing operational efficiency 2.

Key Features

The Diamond Dowel 205366 is characterized by robust construction from high-grade materials, ensuring longevity under demanding conditions. Its precise dimensions and smooth surface are designed for easy installation and secure fit, reducing misalignment likelihood. Additionally, its design may incorporate features that enhance resistance to corrosion and wear, contributing to its reliability in commercial truck applications 3.

Benefits

Using the Diamond Dowel 205366 in truck maintenance and repair offers enhanced durability, improved performance, and ease of installation. Its robust construction ensures it can withstand heavy-duty use stresses, while its precise design facilitates quick and accurate installation. These benefits contribute to the truck’s overall efficiency and reliability, reducing downtime and maintenance costs.

Installation Process

Installing the Diamond Dowel 205366 requires a specific procedure for proper fitment and function. The process involves cleaning the installation area, followed by carefully inserting the dowel into its designated position. Ensuring the dowel is fully seated is crucial for achieving desired alignment. Best practices include verifying the dowel’s position before finalizing any component installations to avoid potential issues.

Troubleshooting and Maintenance

Identifying and resolving common issues related to the Diamond Dowel 205366 can involve checking for signs of wear or misalignment during regular maintenance checks. If misalignment is detected, re-evaluating the installation process or considering replacing the dowel may be necessary. Regular maintenance practices, such as cleaning the installation area and inspecting for wear, can help ensure the dowel’s longevity and optimal performance.

Cummins Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components and engines. With a history of innovation and excellence, Cummins has established a reputation for reliability and performance. The company’s commitment to quality and customer satisfaction makes it a trusted name for truck components, including the Diamond Dowel 205366.

Conclusion

The Diamond Dowel 205366 by Cummins is a critical component in the maintenance and operation of commercial trucks. Its role in ensuring precise alignment and support within a truck’s system contributes to the vehicle’s efficient operation and reliability. Understanding its functionality, key features, and benefits is essential for professionals in the field, ensuring they can maintain and repair heavy-duty trucks effectively.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.