This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

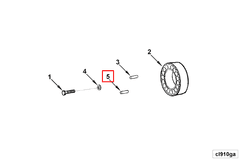

The 3278414 Dowel Pin, manufactured by Cummins, is a component used in the assembly of commercial trucks. Cummins, a well-established name in the commercial truck industry, produces a range of parts designed to enhance the performance and reliability of truck systems. Dowel pins, including the 3278414, play a role in mechanical assemblies by ensuring the precise alignment and secure fitting of components 1.

Basic Concepts of Dowel Pins

Dowel pins are cylindrical rods used in mechanical systems to align and secure components. They function by fitting into corresponding holes in mating parts, thereby maintaining the correct spatial relationship between them. This alignment is crucial for the proper operation and integrity of mechanical assemblies, as it ensures that components interact as intended without undue stress or misalignment 2.

Purpose of the 3278414 Dowel Pin in Truck Operation

The 3278414 Dowel Pin is specifically designed to facilitate the accurate alignment and secure fitting of components within truck assemblies. By ensuring that parts are correctly positioned relative to one another, this dowel pin contributes to the overall structural integrity and operational efficiency of the truck. Its role is particularly important in assemblies where precise alignment is necessary for optimal performance and durability 3.

Key Features

The 3278414 Dowel Pin is characterized by several key features that enhance its functionality. It is typically made from a durable material, such as steel, which provides the necessary strength and resistance to wear. The dimensions of the pin are precisely engineered to fit specific applications, ensuring a snug and secure fit. Additionally, the design may include features such as chamfered ends to facilitate easy insertion and removal.

Benefits of Using the 3278414 Dowel Pin

Utilizing the 3278414 Dowel Pin offers several advantages in truck assemblies. It improves alignment accuracy, which is vital for the proper functioning of mechanical components. The durable material composition enhances the pin’s longevity, reducing the need for frequent replacements. Moreover, the reliable performance of the dowel pin contributes to the overall stability and efficiency of the truck’s mechanical systems.

Installation Process

Installing the 3278414 Dowel Pin requires careful attention to ensure correct placement and function. The process involves cleaning the mating surfaces to remove any debris that could affect alignment. The pin is then inserted into the pre-drilled holes in the components it is meant to align. Tools such as a press or a hammer may be used to ensure the pin is seated properly without damage. It is important to verify that the pin is fully engaged and that the components are aligned as intended.

Troubleshooting Common Issues

Common issues with dowel pins, such as misalignment or wear, can affect the performance of mechanical assemblies. Misalignment may be addressed by re-evaluating the fit of the components and ensuring that the pin is correctly installed. Wear on the pin or mating surfaces can be mitigated by regular inspection and replacement of the pin if necessary. Proper lubrication can also help reduce wear and facilitate easier installation and removal.

Maintenance Tips

Regular maintenance of the 3278414 Dowel Pin is important for ensuring its longevity and consistent performance. This includes periodic inspection for signs of wear or damage. Cleaning the pin and mating surfaces can prevent the buildup of debris that could affect alignment. Additionally, applying a light coat of lubricant can help maintain smooth operation and ease of installation.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality components. With a history of innovation and excellence, Cummins has established a reputation for producing reliable and durable parts that meet the demanding requirements of commercial truck applications. The company’s commitment to quality and performance makes it a trusted source for truck components, including the 3278414 Dowel Pin.

Dowel Pin 3278414 Compatibility with Cummins Engines

The Dowel Pin 3278414, manufactured by Cummins, is a critical component that ensures precise alignment and stability in various engine configurations. This part is designed to fit seamlessly within the engine architecture, providing essential support and alignment for moving parts.

Compatibility with 4B3.9 and 6B5.9 Engines

The Dowel Pin 3278414 is compatible with both the 4B3.9 and 6B5.9 engines. These engines, known for their robust performance and reliability, benefit from the precision and durability of this dowel pin. It ensures that the internal components maintain their correct positions, which is crucial for the smooth operation and longevity of the engine.

Compatibility with ISB/ISD 6.7 CM2150 SN, ISBE CM2150, and ISBE4 CM850 Engines

The Dowel Pin 3278414 also fits within the ISB/ISD 6.7 CM2150 SN, ISBE CM2150, and ISBE4 CM850 engines. These engines, part of Cummins’ advanced lineup, are designed for high-performance applications. The dowel pin’s role in these engines is to maintain the alignment of critical components, ensuring that the engine operates efficiently and reliably under demanding conditions.

Each of these engines, while differing in specific configurations and applications, relies on the Dowel Pin 3278414 to provide the necessary stability and precision. This compatibility underscores the versatility and importance of the dowel pin in Cummins’ engine designs.

Role of Part 3278414 Dowel Pin in Engine Systems

The Dowel Pin, identified by part number 3278414, is an essential component in ensuring the precise alignment and stability of various engine systems. Its application spans across multiple components, contributing to the overall efficiency and reliability of the engine.

Alignment in Compressor Arrangements

In compressor systems, the Dowel Pin is utilized to maintain the exact positioning of the compressor components. This alignment is vital for the compressor’s ability to effectively compress air or refrigerant, which is a fundamental function in both air conditioning and refrigeration systems. The Dowel Pin ensures that the compressor’s moving parts are correctly aligned, reducing wear and tear and enhancing the system’s longevity.

Stability in Coolant Systems

Within coolant systems, the Dowel Pin plays a role in securing the components that manage the flow of coolant. Proper alignment facilitated by the Dowel Pin ensures that coolant is distributed evenly throughout the engine, preventing hotspots and ensuring consistent engine temperature. This is particularly important in high-performance engines where thermal management is key to maintaining efficiency and preventing damage.

Clutch Mechanism Precision

In clutch systems, the Dowel Pin is instrumental in aligning the clutch components, ensuring smooth engagement and disengagement. This precision is essential for the clutch’s performance, affecting gear changes and overall drivability. The Dowel Pin helps in maintaining the integrity of the clutch assembly, reducing the likelihood of slippage or failure under load.

Rear Component Integration

At the rear of the engine, the Dowel Pin is used to align components such as exhaust manifolds or rear-mounted accessories. This alignment is important for the structural integrity of the engine and for the efficient operation of rear-mounted systems. The Dowel Pin ensures that these components are securely in place, contributing to the engine’s stability and performance.

Conclusion

In summary, the Dowel Pin (part 3278414) is a small yet significant component that enhances the functionality and reliability of various engine systems. Its role in alignment and stability is fundamental to the operation of compressors, coolant systems, clutches, and rear components, making it an indispensable part of engine design and maintenance.

-

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ -

Kirk T Van Gelder, Fundamentals of Automotive Technology Principles and Practice, Jones Bartlett Learning, 2018.

↩ -

Michael Klyde and Kirk VanGelder, Advanced Automotive Electricity and Electronics, Jones Bartlett Learning, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.