This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

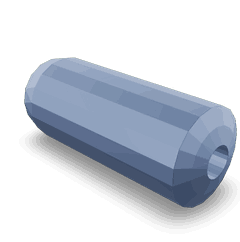

The Cummins 3420769 Pin Dowel is a component designed for use in heavy-duty truck applications. Its purpose is to ensure precise alignment and stability between mating parts within the engine or transmission assemblies. This part contributes to the overall efficiency and reliability of the truck’s mechanical systems 2.

Basic Concepts of Pin Dowels

A pin dowel is a cylindrical rod used in mechanical assemblies to align and secure components in place. It plays a role in maintaining the correct positional relationship between parts, which is vital for the smooth operation and longevity of the assembly. By preventing relative movement, pin dowels help to distribute loads evenly and reduce wear on mating surfaces 3.

Purpose of the Cummins 3420769 Pin Dowel

The Cummins 3420769 Pin Dowel is specifically designed to facilitate the accurate alignment of components within heavy-duty truck engines or transmissions. It ensures that parts fit together correctly, which is important for the efficient transfer of power and the reduction of mechanical stress. This alignment is particularly important in high-stress environments typical of heavy-duty applications 1.

Key Features

The Cummins 3420769 Pin Dowel is characterized by its robust material composition, typically made from high-grade steel to withstand the rigors of heavy-duty use. Its dimensions are precisely engineered to fit specific applications, ensuring a snug fit that resists movement. The design includes features that enhance its performance and durability, such as a smooth surface finish to minimize friction and potential galling 2.

Benefits

The use of the Cummins 3420769 Pin Dowel offers several advantages. It improves the alignment of components, which can lead to reduced wear on mating parts. This alignment also contributes to the enhanced reliability of the truck’s mechanical systems by ensuring that parts operate within their designed parameters. Additionally, the dowel’s durable construction helps to maintain performance over the long term 3.

Installation Process

Installing the Cummins 3420769 Pin Dowel requires careful attention to ensure correct placement and function. The process involves cleaning the dowel hole to remove any debris, inserting the dowel, and verifying that it is seated properly. Tools such as a press may be required to ensure the dowel is fully inserted without damage. Proper installation is important for the dowel to perform its intended function effectively 1.

Troubleshooting Common Issues

Common issues with pin dowels include misalignment and wear. Misalignment can occur if the dowel is not properly seated or if the mating components are not correctly positioned. Wear may result from excessive movement or inadequate material quality. Troubleshooting steps include re-evaluating the installation process, inspecting for damage, and replacing the dowel if necessary to restore proper function 2.

Maintenance Tips

Regular maintenance of the Cummins 3420769 Pin Dowel involves periodic inspection for signs of wear or damage. Cleaning the dowel and its surrounding area can prevent the accumulation of debris that might affect performance. If significant wear is observed, or if the dowel no longer fits securely, replacement should be considered to maintain the integrity of the assembly 3.

Compatibility with Cummins Engines

The Pin Dowel part number 3420769, manufactured by Cummins, is designed to fit seamlessly within a variety of Cummins engine models. This part is integral to the engine’s assembly and operational integrity, ensuring precise alignment and stability of moving parts.

QSV81G and QSV91G Engines

The Pin Dowel part 3420769 is compatible with the QSV81G and QSV91G engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications. The pin dowel’s role in these engines is to maintain the alignment of various components, contributing to the engine’s overall efficiency and longevity 1.

QSV91-G4 CM558/CM700 V102 Engine

For the QSV91-G4 CM558/CM700 V102 engine, the Pin Dowel part 3420769 is specifically engineered to fit the unique design and specifications of this model. This engine is part of a series that emphasizes advanced technology and performance, making the pin dowel’s precision fit essential for maintaining the engine’s operational standards 2.

QSW/QSV82 and QSW73 Engines

The Pin Dowel part 3420769 also fits within the QSW/QSV82 and QSW73 engines. These engines are designed for versatility and efficiency, often used in a range of applications from industrial to commercial use. The pin dowel’s compatibility with these engines ensures that the components remain aligned, which is crucial for the engine’s smooth operation and durability 3.

Role of Part 3420769 Pin Dowel in Engine Systems

The Part 3420769 Pin Dowel is a component in ensuring the precise alignment and secure fitting of various engine system components. Its application spans across multiple assemblies, contributing to the overall efficiency and reliability of the engine.

Flywheel Assembly

In the Flywheel Assembly, the Pin Dowel ensures that the flywheel is correctly aligned with the crankshaft. This alignment is vital for the smooth transfer of power from the engine to the transmission. The Pin Dowel helps maintain the exact positional relationship between these components, reducing wear and tear and enhancing the durability of the assembly 1.

Heat Exchanger Components

For the Heat Exchanger and its associated assemblies such as the Heat Exchanger Assembly Support and Heat Exchanger Mounting Supply, the Pin Dowel plays a significant role in maintaining structural integrity. It ensures that the heat exchanger components are accurately positioned relative to each other, which is essential for optimal heat transfer efficiency. Proper alignment facilitated by the Pin Dowel prevents leaks and ensures that the cooling system operates within specified parameters 2.

Exchanger Heat Assembly

In the Exchanger Heat Assembly, the Pin Dowel is used to secure the various plates and passages that facilitate heat exchange. Accurate alignment of these components is necessary to maintain the flow of coolant and ensure that the heat exchange process is efficient. The Pin Dowel contributes to the stability of the assembly, which is crucial for consistent performance under varying operating conditions 3.

Heat Assembly Exchanger

Similarly, in the Heat Assembly Exchanger, the Pin Dowel ensures that all components are correctly aligned, allowing for efficient heat dissipation. This is particularly important in high-performance engines where thermal management is a key factor in maintaining engine health and performance 1.

Flywheel and Flywheel Assembly

The Pin Dowel also ensures that the Flywheel and Flywheel Assembly are correctly mated with the engine block and transmission components. This precise alignment is necessary for the balanced operation of the engine, reducing vibrations and enhancing the overall smoothness of engine operation 2.

Conclusion

The Cummins 3420769 Pin Dowel is a fundamental component in various engine system assemblies, ensuring that all parts are accurately aligned and securely fitted. This contributes to the efficient operation, durability, and reliability of the engine system. Regular maintenance and proper installation are key to maximizing the benefits of this part 3.

-

Cummins Inc., Troubleshooting and Repair Manual, Bulletin Number 4358343, QSL9 M CM2250 L106.

↩ ↩ ↩ ↩ ↩ -

Alma Hillier, Fundamentals of Motor Vehicle Technology Book 1 6th Edition, Oxford University Press, 2014.

↩ ↩ ↩ ↩ ↩ ↩ -

P. A. Lakshminarayanan and Avinash Kumar, Design and Development of Heavy Duty Diesel Engines: A Handbook, Springer Nature, 2020.

↩ ↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.