This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4101000 Dowel Ring, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This part plays a significant role in the assembly and alignment of truck components, contributing to the overall performance and reliability of heavy-duty vehicles. Understanding the function and importance of this Cummins part is essential for maintaining and optimizing truck operations.

Basic Concepts of Dowel Rings

A dowel ring is a cylindrical component used in mechanical assemblies to align and secure parts together. It ensures that components are correctly positioned relative to each other, which is vital for the proper functioning of machinery. In the context of truck components, dowel rings help maintain the precise alignment of parts, which is crucial for the durability and efficiency of the vehicle 1.

Purpose of the 4101000 Dowel Ring

The 4101000 Dowel Ring is designed to align and secure components within a truck’s mechanical system. Its primary function is to ensure that parts are correctly positioned, which helps in maintaining the structural integrity and operational efficiency of the truck. By providing a stable and accurate alignment, the dowel ring contributes to the smooth operation of the vehicle 2.

Key Features

This part is designed with specific features that enhance its performance and durability. It is typically made from high-quality materials that can withstand the rigors of heavy-duty use. The dimensions and design of the dowel ring are carefully engineered to ensure a precise fit and reliable function within the truck’s mechanical system 3.

Benefits

The use of the 4101000 Dowel Ring offers several benefits. It improves the alignment of components, which is important for the overall structural integrity of the truck. Additionally, by ensuring that parts are correctly positioned, the dowel ring contributes to the efficiency and reliability of the vehicle. This can lead to reduced wear and tear on other components, potentially extending the lifespan of the truck 4.

Installation Process

Proper installation of the 4101000 Dowel Ring is important for its effective function. The process involves carefully positioning the dowel ring within the designated area and securing it in place. It is important to follow best practices during installation to avoid common pitfalls, such as misalignment or improper fitting, which could affect the performance of the truck.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the longevity and optimal performance of the 4101000 Dowel Ring. Common issues may include misalignment or wear, which can be identified through routine inspections. Addressing these issues promptly can help maintain the efficiency and reliability of the truck.

Cummins: Manufacturer Overview

Cummins Inc. is a reputable manufacturer in the automotive and heavy-duty truck industry. With a history of innovation and commitment to quality, Cummins has established itself as a trusted name in the production of truck components. The company’s dedication to excellence is reflected in the design and performance of its products, including the 4101000 Dowel Ring.

Dowel Ring Part 4101000 in Cummins Engines

The Dowel Ring part 4101000, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the proper functioning and alignment of various engine parts, ensuring smooth operation and longevity of the engine.

QSK45 CM500 and QSK60 CM500

In the QSK45 CM500 and QSK60 CM500 engines, the Dowel Ring part 4101000 plays a vital role in maintaining the alignment between the crankshaft and the connecting rods. This alignment is crucial for the efficient transfer of power from the engine to the drivetrain, ensuring optimal performance and reducing wear on engine components.

QSK60 CM850 MCRS and QSK60G

For the QSK60 CM850 MCRS and QSK60G engines, the Dowel Ring part 4101000 is similarly essential. It ensures the precise alignment of the crankshaft and connecting rods, which is critical for the high-performance demands of these engines. The MCRS variant, in particular, benefits from this alignment as it is designed for heavy-duty applications, requiring robust and reliable components to handle the increased stress and load.

The Dowel Ring part 4101000 is designed to withstand the rigors of continuous operation in demanding environments, providing a stable and secure fit that is essential for the overall integrity of the engine.

Role of Part 4101000 Dowel Ring in Engine Systems

The Part 4101000 Dowel Ring is integral to the precise alignment and assembly of various engine components. Its primary function is to ensure that parts are correctly positioned relative to one another, which is essential for the engine’s performance and longevity.

Camshaft and Cylinder Head Alignment

In the assembly of the camshaft and cylinder head, the Dowel Ring plays a significant role. It ensures that the camshaft is accurately aligned with the cylinder head, which is vital for the proper operation of the valve train. Misalignment can lead to issues such as valvetrain noise, reduced efficiency, and potential damage to the camshaft or cylinder head.

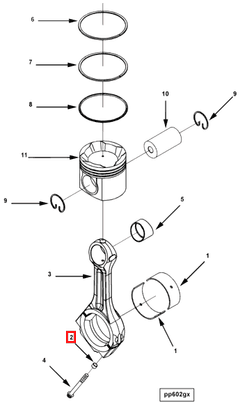

Engine Connecting Rod and Piston Kit Integration

When integrating the engine connecting rod with the engine piston kit, the Dowel Ring assists in maintaining the correct orientation. This is particularly important during the assembly of the engine top-level assembly piston, where precise alignment between the connecting rod and piston is necessary to ensure smooth operation and prevent premature wear.

Injector Placement

The Dowel Ring also facilitates the accurate placement of the injector within the engine assembly. Proper injector alignment is essential for optimal fuel delivery and combustion efficiency. Any deviation can result in inefficient fuel burn, increased emissions, and reduced engine performance.

Overall Engine Performance

By ensuring the correct alignment of these components, the Dowel Ring contributes to the overall performance and reliability of the engine. It helps in achieving the designed specifications and tolerances, which are critical for the engine to operate within its intended parameters.

Alternative Design Considerations

In some alternative engine designs, the Dowel Ring may be used in conjunction with other alignment tools to enhance precision. This can be particularly beneficial in high-performance engines where even minor misalignments can have significant impacts on engine efficiency and durability.

Conclusion

The 4101000 Dowel Ring is a key component in the accurate assembly and alignment of various engine parts, directly influencing the engine’s performance and reliability. Its role in maintaining precise alignment between critical components ensures the smooth operation and longevity of heavy-duty engines, making it an indispensable part in Cummins’ engine systems.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Taghavifar, Hamid and Mardani, Aref. Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer, 2017.

↩ -

Livesey, Andrew. The Repair of Vehicle Bodies. Elevier, 2000.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.