4974994

Ring Dowel

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 4974994 Ring Dowel, a component manufactured by Cummins, is integral to the commercial truck industry. This Cummins part ensures the precise alignment and fit of various engine and transmission parts, highlighting its significance within truck components.

Basic Concepts of Ring Dowels

A ring dowel is a mechanical component used to align and secure parts within an assembly. In truck engine or transmission systems, ring dowels maintain the correct positioning of components, which is vital for efficient operation and durability. They provide a reference point for alignment, ensuring parts are correctly mated and secured 1.

Purpose of the 4974994 Ring Dowel

The 4974994 Ring Dowel aligns components within the engine or transmission, ensuring proper fit. This alignment is essential for the structural integrity of the assembly, preventing excessive wear, misalignment, and potential failure of the components. By maintaining precise alignment, the ring dowel contributes to the overall efficiency and reliability of the truck’s engine or transmission system 2.

Key Features

The 4974994 Ring Dowel is characterized by its material composition, designed to withstand the rigors of engine and transmission operation, and its precise dimensions, which ensure accurate alignment. Unique design elements further contribute to its effectiveness in maintaining component alignment and fit 3.

Benefits

Utilizing the 4974994 Ring Dowel offers several advantages, including improved alignment precision, enhanced component longevity, and potential cost savings through reduced maintenance needs. Proper alignment reduces wear and tear, and components that are properly aligned are less likely to fail prematurely.

Installation Process

Correct installation of the 4974994 Ring Dowel is crucial for its effectiveness. The process involves aligning the dowel with corresponding components and securing it in place. Best practices include verifying the cleanliness and condition of mating surfaces before installation and using appropriate tools to ensure the dowel is properly seated. Avoiding common pitfalls, such as forcing the dowel into place or neglecting to check alignment, is crucial for a successful installation.

Troubleshooting and Maintenance

Identifying common issues related to the 4974994 Ring Dowel, such as misalignment or wear, is important for maintaining optimal performance. Regular inspections can help detect these issues early, allowing for timely corrections. Recommended maintenance practices include cleaning the dowel and its mating surfaces, checking for proper alignment during routine maintenance, and replacing the dowel if significant wear or damage is detected.

Cummins: Manufacturer Overview

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its wide range of high-quality engine and component products. With a history of innovation and reliability, Cummins has established a strong reputation for producing durable and efficient components. This background underscores the quality and reliability of the 4974994 Ring Dowel, reflecting Cummins’ commitment to excellence in the commercial truck sector.

Compatibility with Cummins Engines

The Ring Dowel part number 4974994 is compatible with various Cummins engine models, ensuring alignment and stability of the piston rings for optimal engine performance and longevity.

ISX12 Series

- ISX12 CM2350 X102

- ISX12 G CM2180 EJ

- ISX12/ISX11.9 CM2250

ISZ13 Series

- ISZ13 CM2150 Z105

QSX11.9 Series

- QSX11.9 CM2250 ECF

QSZ13 Series

- QSZ13 CM2150 Z101

- QSZ13 CM2150 Z102

Z13 Series

- Z13 Z108G

Role of Part 4974994 Ring Dowel in Engine Systems

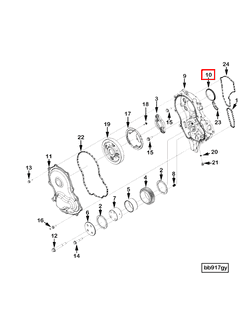

The 4974994 Ring Dowel is instrumental in ensuring the precise alignment and secure fitting of various components within engine systems. Its application is particularly significant in the assembly and maintenance of the Gear Housing, Housing, and Front Gear.

Gear Housing

In the Gear Housing, the Ring Dowel facilitates the accurate positioning of the housing relative to other engine components. This alignment is essential for the efficient transfer of power and the reduction of wear and tear on the gear teeth. The Ring Dowel ensures that the Gear Housing is correctly seated, which is vital for the overall stability and performance of the engine.

Housing Assembly

Within the broader Housing assembly, the Ring Dowel plays a key role in maintaining the structural integrity of the engine. It helps in securing the housing in place, preventing any misalignment that could lead to increased friction or potential damage to the engine components. This is particularly important in high-stress environments where precision and reliability are paramount.

Front Gear

For the Front Gear, the Ring Dowel is essential in ensuring that the gear is properly aligned with the other components of the engine. This alignment is critical for the smooth operation of the engine, as it ensures that the gear engages correctly with its counterparts, thereby optimizing power transmission and minimizing the risk of mechanical failure.

Conclusion

The 4974994 Ring Dowel is a fundamental component in the assembly and maintenance of engine systems, contributing to their efficiency, durability, and reliability. Its precise alignment capabilities ensure the optimal performance of various engine components, underscoring its importance in the commercial truck industry.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.