This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

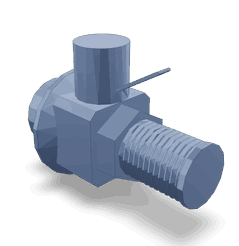

The Cummins 3328520 Draincock is a component designed for use in commercial trucks. It serves a specific function in the maintenance routines of these vehicles, facilitating the drainage of various fluids. Understanding its purpose and role is fundamental for effective truck maintenance.

Basic Concepts of a Draincock

A draincock is a valve used to release fluid from a system. It operates by allowing the controlled release of liquids such as coolant, oil, or fuel from a tank or system. In the context of trucks, draincocks play a role in fluid management by enabling the safe and efficient drainage of fluids during maintenance or repair procedures 1.

Purpose of the Cummins 3328520 Draincock

The Cummins 3328520 Draincock is designed to facilitate the drainage of fluids in commercial trucks. It is used in systems where the periodic removal of fluids is necessary, such as during coolant changes, oil changes, or fuel system maintenance. By providing a means to drain these fluids, the draincock contributes to the overall maintenance and operational efficiency of the truck 2.

Key Features

The Cummins 3328520 Draincock is characterized by its robust design and the materials used in its construction. It is engineered to withstand the pressures and temperatures associated with truck fluid systems. The draincock may include features such as a threaded connection for secure fitting, a handle for easy operation, and a sealing mechanism to prevent leaks during non-use 3.

Benefits of Using the Cummins 3328520 Draincock

Incorporating the Cummins 3328520 Draincock into truck maintenance routines offers several advantages. It allows for efficient fluid drainage, which is vital for maintaining system cleanliness and performance. The design of the draincock also contributes to safety by providing a controlled means of fluid release, reducing the risk of spills or accidents. Additionally, its durable construction helps ensure a prolonged component lifespan, offering value over time.

Installation and Usage Guidelines

Proper installation and usage of the Cummins 3328520 Draincock involve several steps. It should be installed in accordance with the manufacturer’s instructions, ensuring a secure and leak-proof connection. When in use, the draincock should be operated carefully to avoid damage and ensure the safe release of fluids. Regular checks for wear or damage are recommended to maintain optimal performance.

Troubleshooting and Maintenance

Common issues with the Cummins 3328520 Draincock may include leaks, difficulty in operation, or corrosion. Troubleshooting these issues involves inspecting the draincock for signs of wear, ensuring proper installation, and addressing any corrosion with appropriate treatments. Regular maintenance, such as cleaning and checking for secure fittings, can help prevent issues and ensure reliable operation.

Safety Considerations

When working with the Cummins 3328520 Draincock, it is important to follow safety guidelines. This includes allowing fluids to cool before drainage to avoid burns, ensuring proper sealing to prevent leaks, and using appropriate personal protective equipment. Adhering to these safety practices helps protect both the operator and the vehicle.

Environmental Impact

The use and disposal of the Cummins 3328520 Draincock should consider environmental impact. Proper disposal of drained fluids is crucial to prevent environmental contamination. Recycling options for the draincock itself may be available, depending on local regulations and facilities. Responsible handling and disposal practices contribute to minimizing the environmental footprint of truck maintenance activities.

Compatibility with Cummins Engines

The Cummins draincock part number 3328520 is designed to fit a range of Cummins engines, ensuring efficient maintenance and operation. This part is integral to the engine’s cooling system, facilitating the removal of water and contaminants. Below is a detailed look at the compatibility of this draincock with various Cummins engines.

K Series Engines

- K38

- K50

The draincock 3328520 is compatible with the K38 and K50 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications.

M11 Series Engines

- M11 CELECT PLUS

- M11 MECHANICAL

Both the M11 CELECT PLUS and M11 MECHANICAL engines are equipped with the 3328520 draincock. This part ensures that the cooling system can be effectively drained, which is crucial for maintenance and preventing system failures.

N14 Series Engines

- N14 MECHANICAL

The N14 MECHANICAL engine utilizes the 3328520 draincock. This engine is recognized for its power and efficiency, making the draincock an essential component for its maintenance.

NH/NT Series Engines

- NH/NT 855

The NH/NT 855 engine is also compatible with the 3328520 draincock. This engine is designed for versatility and performance, and the draincock plays a key role in maintaining its cooling system.

QSM11 Series Engines

- QSM11 CM570

The QSM11 CM570 engine is another model that fits the 3328520 draincock. This engine is engineered for durability and efficiency, making the draincock a vital part of its maintenance routine.

QSN14 Series Engines

- QSN14 CM876 N103

The QSN14 CM876 N103 engine is compatible with the 3328520 draincock. This engine is known for its high performance and reliability, and the draincock ensures that its cooling system is maintained properly.

By ensuring that the draincock 3328520 is compatible with these various Cummins engines, maintenance becomes more streamlined, and the engines can operate more efficiently.

Role of Part 3328520 Draincock in Engine Systems

The part 3328520 Draincock is an essential component in various engine systems, facilitating the efficient management of fluids. In the context of a drain system, this component allows for the controlled release of accumulated fluids, ensuring that the system remains free of contaminants and operates smoothly.

When integrated into a remote oil system, the Draincock plays a significant role in maintaining the integrity of the oil supply. It enables the periodic draining of oil, which is necessary for removing impurities and sediment that may have settled within the system. This process helps in preserving the quality of the oil, thereby enhancing the performance and longevity of the engine.

In conjunction with an oil valve, the Draincock ensures that the oil flow within the system is regulated effectively. The valve controls the direction and rate of oil flow, while the Draincock provides a means to evacuate the oil when necessary. This synergy is vital for maintaining optimal oil levels and pressure within the engine, which are critical for its efficient operation.

Furthermore, within an oil drain system, the Draincock is instrumental in the routine maintenance procedures. It allows for the straightforward removal of oil during changes or inspections, ensuring that the engine is always supplied with clean, fresh oil. This not only improves the engine’s performance but also reduces the risk of mechanical failures due to contaminated oil.

Conclusion

The Cummins 3328520 Draincock is a vital component in the maintenance of commercial trucks, offering efficient fluid drainage and contributing to the overall performance and longevity of the vehicle. Its robust design, compatibility with various Cummins engines, and role in maintaining fluid systems make it an indispensable part of truck maintenance routines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.