This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

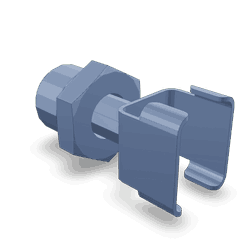

The Cummins 4068269 Draincock is a critical component for commercial trucks, designed to facilitate the efficient drainage of fluids from various systems within the vehicle. This part ensures that maintenance and service procedures can be performed with ease, contributing to the operational integrity of trucks by allowing for the safe and controlled release of fluids such as fuel, coolant, and lubrication oil.

Basic Concepts of Draincocks

A draincock is a valve designed to release fluid from a system, providing a controlled opening for fluid expulsion. In trucks, draincocks are essential for fluid management, enabling the periodic removal of contaminants, old fluid, or for system flushing. Proper fluid management is vital for maintaining system efficiency and preventing damage from fluid degradation or contamination 1.

Purpose of the Cummins 4068269 Draincock

The Cummins 4068269 Draincock is specifically designed for use in commercial trucks, serving a crucial function in the operation of these vehicles. It is applied in various systems including fuel, coolant, and lubrication. By allowing for the drainage of these fluids, it supports routine maintenance tasks such as fluid changes and system cleaning, thereby preserving the performance and longevity of the truck’s engine and other components 2.

Key Features

This Cummins part is characterized by several design elements and material choices that enhance its performance and durability. Constructed from materials that resist corrosion and wear, it ensures longevity even in harsh operating environments. The design includes features that facilitate easy operation and secure sealing, minimizing the risk of leaks during and after use 3.

Benefits of Using the Cummins 4068269 Draincock

Utilizing the Cummins 4068269 Draincock offers several advantages. Its design allows for ease of use, making fluid drainage a straightforward process. The reliability of the draincock ensures that fluid can be expelled efficiently without the risk of spillage or incomplete drainage. Furthermore, its robust construction contributes to the overall efficiency of maintenance procedures, reducing downtime and enhancing operational reliability 4.

Installation and Usage

Proper installation and usage of the Cummins 4068269 Draincock involve following manufacturer guidelines to ensure optimal performance. Installation should be conducted with the truck’s engine off and fluids cooled to prevent burns or injuries. The draincock should be tightened to the specified torque to ensure a secure fit and prevent leaks. When draining fluids, it is important to have appropriate containers ready to collect the fluid and dispose of it according to environmental regulations.

Troubleshooting and Maintenance

Common issues with the Cummins 4068269 Draincock may include leaks or difficulty in operation. Troubleshooting these issues often involves checking for proper installation, ensuring the draincock is tightened correctly, and inspecting for signs of wear or damage. Regular maintenance, such as cleaning around the draincock and inspecting for corrosion, can help prolong its lifespan and ensure reliable operation.

Safety Considerations

When working with the Cummins 4068269 Draincock, it is important to observe safety guidelines to protect against injury and ensure proper operation. This includes allowing fluids to cool before drainage to avoid burns, using appropriate personal protective equipment, and ensuring the draincock is properly sealed after use to prevent leaks. Additionally, disposing of drained fluids in accordance with environmental regulations is crucial to avoid contamination.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins has established a reputation for reliability and performance in the automotive and heavy-duty truck industries. The company’s dedication to advancing technology and improving efficiency is reflected in its wide range of products, including the Cummins 4068269 Draincock.

Cummins Draincock Part 4068269 Compatibility

The Cummins draincock part number 4068269 is designed to fit seamlessly with a range of engines, ensuring efficient maintenance and operation. This part is specifically engineered to work with the following Cummins engines:

- QST30 CM552

- QSC 3.8

- QSC 4.5

- QSC 6.7

- QSK 19

- QSK 23

- QSK 38

- QSK 50

- QSK 60

- QSK 95

These engines are part of the Cummins portfolio, known for their robust performance and reliability across various applications. The draincock part 4068269 is integral to these engines, facilitating the removal of unwanted fluids and contaminants, thereby maintaining the engine’s optimal performance.

Role of Part 4068269 Draincock in Engine Systems

Auxiliary Cooling System

The 4068269 Draincock is integral to the auxiliary cooling system, facilitating the periodic release of coolant. This process is essential for maintaining the system’s efficiency and preventing the buildup of contaminants that could impair heat exchange. By allowing for the controlled discharge of coolant, the Draincock ensures that the auxiliary cooling system operates within optimal parameters, thereby supporting the primary cooling system and contributing to the overall thermal management of the engine.

Primary Cooling System

In the primary cooling system, the 4068269 Draincock enables the safe and efficient draining of coolant during maintenance procedures. This is particularly important during coolant changes or when the system requires flushing to remove debris and old coolant. The Draincock’s design allows for a clean and complete discharge, minimizing the risk of coolant residue that could lead to corrosion or reduced cooling efficiency.

Integrated Cooling Systems

For engines equipped with integrated cooling systems, the 4068269 Draincock plays a pivotal role in ensuring that both the primary and auxiliary systems can be serviced independently yet efficiently. This integration allows for more complex thermal management strategies, where the Draincock’s function becomes even more significant in maintaining the balance between different cooling loops.

Maintenance and Service

During routine maintenance, the 4068269 Draincock is used to facilitate the inspection and replacement of coolant. Its strategic placement within the cooling system allows for easy access, reducing the time and effort required for service procedures. This not only enhances the maintainability of the engine but also contributes to the longevity and reliability of the cooling system components.

Thermal Management

Effective thermal management is paramount in engine performance and longevity. The 4068269 Draincock, by enabling the efficient draining and refilling of coolant, plays a key role in this aspect. It ensures that the cooling system can be quickly and effectively serviced, maintaining optimal coolant levels and properties, which are essential for dissipating heat generated during engine operation.

Conclusion

The Cummins 4068269 Draincock is a vital component for the maintenance and operation of commercial trucks. Its design and functionality contribute to the efficiency and reliability of fluid management systems, ensuring that trucks can operate at peak performance. By facilitating the safe and controlled release of fluids, this part plays a crucial role in the maintenance and longevity of truck engines and cooling systems.

-

Hick, H., Kupper, K., & Sorger, H. (2021). Systems Engineering for Automotive Powertrain Development. Springer.

↩ -

Hilgers, M., & Achenbach, W. (2021). Vocational Vehicles and Applications. Springer Vieweg.

↩ -

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.