This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins S923E Draincock is a specialized component designed for commercial trucks, contributing to the maintenance and operation of these vehicles. This part is integral to Cummins Inc.’s product line, aimed at enhancing the performance and reliability of commercial vehicles.

Basic Concepts of Draincocks

A draincock, or drain valve, is a device used to release fluid from a system. It is essential in various fluid systems, including engines, hydraulic systems, and fuel systems. The primary role of a draincock is to allow for the controlled release of fluid, which is crucial for maintenance procedures such as draining old fluid before refilling with new fluid, or for troubleshooting purposes when investigating the presence of contaminants within the system 1.

Purpose and Function of the S923E Draincock

The Cummins S923E Draincock is designed to facilitate the draining of fluids from a truck’s system. It plays a role in maintaining the cleanliness and efficiency of the fluid systems by allowing for the easy removal of fluid when necessary. This component is typically applied in the engine system, where it aids in the routine maintenance of engine oil or other fluids, ensuring that the engine operates within optimal conditions 2.

Key Features

The S923E Draincock is characterized by several key features that enhance its performance and durability. Its design is engineered to provide a secure seal when closed, preventing leaks and ensuring that the system remains pressurized as needed. The materials used in its construction are chosen for their resistance to corrosion and ability to withstand the high temperatures and pressures found within engine systems. Additionally, the draincock may feature a unique design that simplifies the draining process, such as a large opening for quick fluid release or a built-in filter to catch debris during draining 3.

Benefits

The advantages of the S923E Draincock include its ease of use, which simplifies the maintenance process for technicians. Its design contributes to the overall efficiency and reliability of the truck by ensuring that fluid changes and system cleanouts are performed effectively. The durability of the draincock means that it can withstand the rigors of commercial truck operation, reducing the need for frequent replacements and contributing to the longevity of the vehicle’s fluid systems.

Troubleshooting and Maintenance

Common issues with the S923E Draincock may include leaks or difficulty in opening the valve. Troubleshooting steps involve checking for proper seating of the draincock, ensuring there is no debris blocking the valve, and verifying that the threads are not damaged. Maintenance tips include regularly inspecting the draincock for signs of wear or corrosion, ensuring that it is tightened to the manufacturer’s specifications after use, and replacing it if any damage is detected to prevent fluid leaks and system contamination.

Cummins Engine Compatibility with S923E Draincock

The S923E Draincock, manufactured by Cummins, is designed to facilitate the removal of water and contaminants from the engine’s cooling system, ensuring optimal performance and longevity. This part is compatible with a wide range of Cummins engine models, including 4B3.9, 6C8.3, C GAS PLUS CM556, C8.3 G, G8.3, G8.3 CM558, G855, G855 CM558, GTA38 G CMEICS G116C, GTA8.3 CM558, GTA855 CM558 (CM2358) G101, ISC CM2150, ISC CM554, ISC CM850, ISC8.3 CM2250, ISL CM2150, ISL CM554, ISL G CM2180, ISL9 CM2150 SN, ISL9 CM2250, ISL9.5 CM2880 L138, ISM CM570, ISX CM570, K19, and K38 engines. By ensuring that this Cummins part is used with the appropriate engine models, maintenance and operational efficiency can be significantly enhanced, contributing to the overall reliability and performance of the engine systems.

Role of S923E Draincock in Various Engine Components

The S923E Draincock is an essential component in numerous engine systems, facilitating the efficient drainage of fluids. Its application spans across a variety of engine components, ensuring optimal performance and maintenance ease.

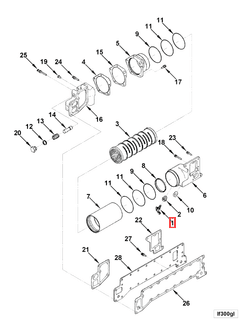

Aftercooler Kit

In the aftercooler kit, the S923E Draincock allows for the periodic drainage of condensed water and other impurities from the cooling system, maintaining the efficiency of the aftercooling process.

Air Intake Manifold

When integrated into the air intake manifold, the draincock enables the removal of any accumulated moisture or debris, ensuring clean air intake and preserving the integrity of the manifold.

Coolant Heater Plumbing

For coolant heater plumbing, the S923E Draincock provides a means to drain coolant, facilitating system flushes and the replacement of coolant, which is vital for consistent heating performance.

Cooler

In cooler systems, whether they are engine coolers or lubricating oil assembly coolers, the draincock is used to evacuate old or contaminated coolant, ensuring the cooler operates efficiently.

Torque Converter

The draincock in the torque converter system allows for the removal of transmission fluid, aiding in routine maintenance and the prevention of component wear.

Crankshaft and Bearings

Although indirectly related, the S923E Draincock’s role in draining engine oil contributes to the overall health of the crankshaft and bearings by ensuring clean lubrication.

Cylinder Block Plumbing

In cylinder block plumbing, the draincock is employed to remove coolant, assisting in the maintenance of the cylinder block’s thermal management system.

Cylinder Mounting Block

Similarly, in the cylinder mounting block, the draincock helps in draining coolant, ensuring that the mounting block remains free from corrosion and scale buildup.

Exhaust Manifold (Wet)

For wet exhaust manifolds, the draincock is utilized to remove condensate and other fluids, maintaining the manifold’s performance and longevity.

Expansion Tank Mounting

In expansion tank systems, the draincock allows for the evacuation of coolant, facilitating the inspection and cleaning of the expansion tank.

Filter Cooler

In filter cooler setups, the draincock is crucial for draining coolant or oil, ensuring the filter remains effective and the cooler operates efficiently.

Filter-Cooler Mounting

For filter-cooler mountings, the draincock enables the drainage of fluids, aiding in the maintenance of the mounting structure and the cooler itself.

Heat and Tank Exchanger

In heat and tank exchangers, the draincock is used to remove fluids, allowing for system maintenance and the prevention of heat exchanger fouling.

Jacket Water Kit

The S923E Draincock in jacket water kits allows for the drainage of water, ensuring the kit’s components remain free from sediment and scale.

Kit

Generic kits often include the S923E Draincock to provide a comprehensive solution for fluid management across various engine components.

Repower

During repowering processes, the draincock is utilized to drain fluids from old systems, preparing them for new installations and ensuring a clean transition.

Manifold (Exhaust Water Cooled)

In exhaust water-cooled manifolds, the draincock facilitates the removal of coolant, maintaining the manifold’s cooling efficiency.

Oil Filter Cooler

For oil filter coolers, the draincock is essential for draining oil, ensuring the filter and cooler remain in optimal condition.

Pressure Switch Mounting

In pressure switch mountings, the draincock allows for the removal of fluids, aiding in the maintenance of the pressure switch system.

Radiator

In radiator systems, the draincock is used to evacuate coolant, facilitating radiator flushes and maintenance.

Short Block

For short blocks, the draincock enables the drainage of engine oil and coolant, ensuring the block’s components remain well-lubricated and cooled.

Short Block 6CTA

Specific to the 6CTA short block, the draincock is utilized for draining fluids, maintaining the engine’s performance and longevity.

To Bracket Mounting (Hot Start)

In hot start bracket mountings, the draincock allows for the removal of fluids, ensuring the system’s readiness for operation.

Turbocharger Mounting

For turbocharger mountings, the draincock is used to drain oil, maintaining the turbocharger’s lubrication and performance.

Water By-Pass Tube

In water by-pass tubes, the draincock facilitates the removal of coolant, ensuring the by-pass system operates efficiently.

Conclusion

The Cummins S923E Draincock is a vital component in the maintenance and operation of commercial trucks. Its design and features contribute to the efficiency and reliability of the vehicle’s fluid systems, ensuring optimal performance and longevity. By understanding the role and benefits of this part, technicians and fleet managers can better maintain their vehicles, leading to improved operational efficiency and reduced maintenance costs.

-

R. Matthew Brach, SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, SAE International, 2023.

↩ -

Tim Giles, Automotive Engines Diagnosis Repair and Rebuilding, Cengage Learning, 2019.

↩ -

John Heywood, Internal Combustion Engine Fundamentals, McGraw-Hill Education, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.