This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tube Connector Elbow 3252444, manufactured by Cummins, is a vital component in the commercial truck industry. This part is integral to the fluid systems of commercial trucks, ensuring efficient and reliable operation. Understanding its role and application is essential for maintaining truck efficiency and reliability.

Basic Concepts

A Tube Connector Elbow is a fitting used in fluid systems to change the direction of fluid flow. It provides a bend in the tubing, allowing fluids to navigate around obstacles or direct flow to different parts of the system. In trucks, these elbows are crucial for fuel, hydraulic, and coolant systems, ensuring fluids are distributed as needed throughout the vehicle.

Purpose of the 3252444 Tube Connector Elbow

The 3252444 Tube Connector Elbow is designed to facilitate the smooth transition of fluid within a truck’s system. It directs fluid flow around corners or bends in the system’s layout, ensuring fluids reach their intended destinations without obstruction. This part helps maintain system integrity by preventing leaks and ensuring consistent fluid pressure throughout the system.

Key Features

The 3252444 Tube Connector Elbow is characterized by several primary features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise engineering to fit seamlessly within the truck’s fluid system, with smooth internal surfaces to minimize flow resistance. Additionally, unique manufacturing processes may be employed to strengthen the elbow, ensuring it can withstand the pressures and temperatures encountered in commercial truck applications.

Benefits

Incorporating the 3252444 Tube Connector Elbow into a truck’s fluid system offers several advantages. It improves fluid dynamics by ensuring smooth and efficient flow, which can enhance the overall performance of the system. The part’s robust construction and design contribute to enhanced system reliability, reducing the likelihood of leaks or failures. Furthermore, by ensuring efficient fluid flow and system integrity, it may lead to potential cost savings through reduced maintenance needs 1.

Installation Considerations

Proper installation of the 3252444 Tube Connector Elbow is crucial for ensuring optimal performance and longevity. Preparatory steps include ensuring the fitting area is clean and free of debris. The use of appropriate tools is recommended to avoid damaging the fitting or the surrounding system. Best practices during installation involve checking for proper alignment and secure fitting to prevent leaks and ensure efficient fluid flow.

Troubleshooting and Maintenance

Identifying common issues with the 3252444 Tube Connector Elbow, such as leaks or blockages, is important for maintaining system efficiency. Regular inspections can help detect early signs of wear or damage. Recommended maintenance practices include cleaning the fitting area before installation or replacement and ensuring all connections are secure. These practices help prevent failures and extend the component’s service life 2.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the commercial truck industry. The company’s extensive product range and commitment to reliability and performance provide context for the quality and dependability of the 3252444 Tube Connector Elbow.

Integration with Engine Components

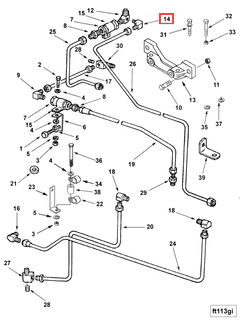

The Tube Connector Elbow 3252444 is utilized in various engine systems to facilitate the smooth and efficient transfer of fluids and gases. Its primary function is to provide a directional change in the flow path of these substances, ensuring they reach their intended destinations within the engine system.

-

Fuel Supply Plumbing: The Tube Connector Elbow is often used in the fuel supply plumbing to redirect the fuel lines, allowing for a more compact and organized layout of the fuel system, reducing the risk of kinks or obstructions that could impede fuel flow.

-

Aftercooler Tube Assembly: In turbocharged engine systems, the aftercooler tube assembly benefits from the use of the Tube Connector Elbow. It helps manage the coolant flow, ensuring that the compressed air is efficiently cooled before entering the engine, thus optimizing performance and reducing the risk of detonation.

-

Manifold Pressure System: The Tube Connector Elbow plays a role in the manifold pressure system by redirecting the pressure lines. This ensures accurate pressure readings and maintains the integrity of the pressure signals sent to the engine control unit (ECU).

-

Turbocharger Location: When installed near the turbocharger, the Tube Connector Elbow assists in routing the intake and exhaust lines. This helps maintain the turbocharger’s efficiency by ensuring that the airflow is directed correctly, minimizing turbulence and pressure drops.

-

Vent Tube Plumbing: In vent tube systems, the Tube Connector Elbow is used to change the direction of vent lines. This is particularly important in fuel systems where venting is necessary to release pressure build-up, ensuring safe and reliable operation.

-

Oil Transfer Connection: The Tube Connector Elbow is also utilized in oil transfer connections, helping to route oil lines efficiently. This is vital for maintaining proper lubrication throughout the engine, especially in high-performance applications where oil flow must be precisely managed.

-

Check Valve Mounting and Drain Check Valve: In systems incorporating check valves, the Tube Connector Elbow aids in the proper installation and orientation of these valves. This ensures that fluid flow is unidirectional and that any accumulated fluids are effectively drained, preventing system contamination.

-

Connector Block and Fuel Block Connector: Within the connector block and fuel block connector systems, the Tube Connector Elbow allows for flexible routing of fuel lines. This is essential for accommodating the complex geometries often found in modern engine bays, ensuring that connections are secure and leak-free.

-

EBM Tubing (Electrical-Braid-Metal Tubing): For fuel and other high-pressure applications, the Tube Connector Elbow is used with EBM tubing to manage sharp bends and transitions. This enhances the durability and reliability of the tubing, protecting it from wear and potential failure points.

-

Hot Start Knock Kit: In systems designed to mitigate hot start knock, the Tube Connector Elbow helps in routing additional fuel or coolant lines. This ensures that the engine receives the necessary components to prevent knocking, thereby enhancing overall engine performance and longevity.

Conclusion

The Tube Connector Elbow 3252444 by Cummins is a critical component in various engine systems, ensuring the smooth and efficient transfer of fluids and gases. Its integration with engine components such as fuel supply plumbing, aftercooler tube assembly, and manifold pressure system highlights its importance in maintaining efficient and reliable engine operation. Proper installation, regular maintenance, and understanding its role in the system are essential for maximizing the performance and longevity of commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.