This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3331617 Male Union Elbow is a component manufactured by Cummins, a well-established name in the commercial vehicle industry. This part holds significance in the fluid systems of commercial trucks, contributing to the efficient operation of these vehicles.

Basic Concepts of Male Union Elbows

A Male Union Elbow is a type of fitting used in fluid systems to connect pipes at an angle. It consists of a male threaded end that screws into a female socket, allowing for secure and leak-proof connections. These fittings are commonly used in various industries for their versatility and ease of installation. The design of a Male Union Elbow typically includes a threaded connection and a union nut, which enables the fitting to be easily disassembled for maintenance or replacement 1.

Purpose of the 3331617 Male Union Elbow in Truck Systems

In commercial truck systems, the 3331617 Male Union Elbow plays a role by facilitating the connection between different components within the truck’s fluid systems. It allows for the redirection of fluid flow at an angle, which is often necessary to navigate the complex layout of pipes and hoses in a truck’s engine compartment. This fitting ensures a secure and reliable connection, contributing to the overall efficiency and performance of the truck’s fluid systems 2.

Key Features of the 3331617 Male Union Elbow

The 3331617 Male Union Elbow is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The fitting includes a male threaded end for secure connection and a union nut that allows for easy disassembly. Additionally, the design of the elbow may incorporate features such as reinforced walls or specialized coatings to further improve its performance in demanding environments 3.

Benefits of Using the 3331617 Male Union Elbow

Incorporating the 3331617 Male Union Elbow into truck systems offers several advantages. Its design promotes improved fluid flow by minimizing restrictions and turbulence. The ease of installation and disassembly facilitated by the union nut simplifies maintenance procedures, reducing downtime. Furthermore, the robust construction of the fitting contributes to its reliability, ensuring consistent performance over time.

Installation Considerations

When installing the 3331617 Male Union Elbow, it is important to follow guidelines and best practices to ensure a proper and secure connection. Necessary tools may include a wrench for tightening the union nut and a pipe cutter for trimming pipes to the correct length. Steps for proper installation involve cleaning the mating surfaces, applying thread sealant if required, and tightening the union nut to the recommended torque specification. Common pitfalls to avoid include over-tightening, which can damage the fitting, and neglecting to check for leaks after installation.

Troubleshooting Common Issues

Common problems associated with the 3331617 Male Union Elbow may include leaks or blockages. To address these issues effectively, it is important to conduct a thorough inspection of the fitting and surrounding components. Leaks may be caused by improper installation, damaged threads, or insufficient thread sealant. Blockages can occur due to debris or corrosion within the fitting. Troubleshooting steps may involve disassembling the fitting, cleaning or replacing damaged components, and reassembling with proper torque and sealant application.

Maintenance Tips

To ensure the longevity and optimal performance of the 3331617 Male Union Elbow, regular maintenance practices are recommended. Inspection routines should include checking for signs of wear, corrosion, or leaks. Cleaning procedures may involve removing debris or buildup from the fitting and surrounding components. Additionally, periodically verifying the tightness of the union nut can help prevent leaks and ensure a secure connection.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial vehicle industry, known for its history of innovation and commitment to quality. The company offers a wide range of products, including engines, powertrains, and components, designed to meet the demanding requirements of commercial applications. Cummins’ reputation for reliability and performance is built on a foundation of rigorous testing, advanced manufacturing processes, and a dedication to customer satisfaction.

Compatibility of Male Union Elbow Part 3331617 with Cummins Engines

The Male Union Elbow part number 3331617, manufactured by Cummins, is designed to fit seamlessly with a range of Cummins engines. This part is integral in ensuring the proper connection and functionality of the engine’s cooling system, providing a secure and leak-proof joint between different sections of the system.

QSK19 Series Engines

The QSK19 series engines, including the QSK19 CM2350 K105, QSK19 CM2350 K114, QSK19 CM500, and QSK19 CM850 MCRS, are all compatible with the Male Union Elbow part 3331617. These engines are known for their robust design and high performance, making them suitable for a variety of heavy-duty applications. The part ensures that the cooling system’s integrity is maintained, preventing any coolant leaks that could lead to engine overheating or damage.

VTA903 Series Engine

The VTA903 CM2250 V105 engine also benefits from the use of the Male Union Elbow part 3331617. This engine, like the QSK19 series, is engineered for durability and efficiency, often used in demanding industrial and marine environments. The part’s precision fit and robust construction are critical in maintaining the engine’s cooling system performance, ensuring optimal operation under various conditions.

By integrating the Male Union Elbow part 3331617 into these engines, Cummins ensures that the cooling system components are securely connected, enhancing the overall reliability and longevity of the engines. This compatibility highlights Cummins’ commitment to providing high-quality, durable parts that meet the rigorous demands of their engine systems.

Role of Part 3331617 Male Union Elbow in Engine Systems

The 3331617 Male Union Elbow is a pivotal component in various engine systems, facilitating the efficient transfer of fluids and gases. In the Cylinder Head assembly, this part ensures a secure connection between the coolant passages and the engine block, maintaining optimal coolant flow to regulate engine temperature.

Within the Housing units, particularly in the Thermostat housing, the Male Union Elbow allows for the precise control of coolant flow into the engine, ensuring that the engine reaches its operating temperature quickly and maintains it consistently.

In Plumbing systems, this component is often used to connect various hoses and pipes, providing a leak-free seal that is essential for the integrity of the cooling and lubrication systems.

For Turbocharger applications, the Male Union Elbow is employed in the oil feed lines, ensuring that the turbocharger receives a consistent supply of lubrication, which is vital for its performance and longevity.

In electrical systems, particularly those involving a Resistor, this part can be used in the cooling circuits to manage the flow of coolant through the resistor, helping to dissipate heat effectively.

Lastly, in environments where Corrosion is a concern, the Male Union Elbow’s robust construction helps to prevent leaks and maintain the system’s integrity, even in the presence of corrosive fluids.

Overall, the 3331617 Male Union Elbow plays a significant role in ensuring the reliable operation of various engine components by providing secure, leak-free connections.

Conclusion

The 3331617 Male Union Elbow is a critical component in the fluid systems of commercial trucks and engines, offering secure, leak-proof connections that enhance the efficiency and reliability of these systems. Its compatibility with various Cummins engines underscores the importance of using high-quality, durable parts in demanding applications. Regular maintenance and proper installation practices are essential to ensure the longevity and optimal performance of this fitting.

SPECIFICATIONS

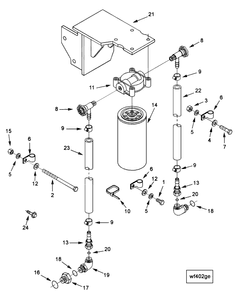

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 1 | 3046201 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.