This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

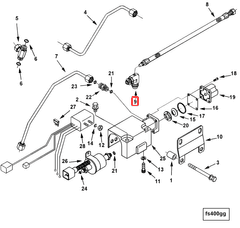

The Male Union Elbow (Part #4001987) by Cummins is a specialized component designed for use in commercial trucks. Its primary purpose is to facilitate the connection and redirection of fluid flow within various systems of the vehicle. This part is integral to maintaining the efficiency and reliability of fluid transfer systems in commercial trucks.

Basic Concepts of Male Union Elbow

A Male Union Elbow is a type of fitting used in fluid systems to join pipes or hoses at an angle. It consists of a male threaded end that connects to a female fitting, allowing for secure and leak-proof connections. The elbow component enables a change in direction of the fluid flow, which is often necessary in the complex routing of pipes within a truck’s system. This fitting is typically made from durable materials to withstand the pressures and temperatures encountered in these applications 1.

Role of the Male Union Elbow in Truck Operations

In the operation of a commercial truck, the Male Union Elbow plays a role in the fluid transfer systems by providing a means to connect and redirect fluid flow. It is commonly used in systems such as hydraulic, fuel, and coolant circuits where changes in direction are required without compromising the integrity of the fluid pathway. This fitting ensures that fluids are efficiently transferred throughout the system, contributing to the overall performance and reliability of the truck 2.

Key Features of the Cummins Male Union Elbow

The Cummins Male Union Elbow is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise threading for a secure connection, and the elbow angle is carefully engineered to facilitate optimal fluid flow. Additionally, the fitting is easy to install and remove, which simplifies maintenance procedures 3.

Benefits of Using the Cummins Male Union Elbow

Utilizing the Cummins Male Union Elbow offers several advantages. Its robust construction contributes to durability and longevity, reducing the need for frequent replacements. The reliable connection it provides helps prevent leaks, which is critical for maintaining system efficiency. Furthermore, the design of the fitting allows for straightforward installation, minimizing downtime during maintenance operations.

Installation Procedures

To install the Male Union Elbow, begin by ensuring that the mating surfaces are clean and free of debris. Apply a compatible thread sealant to the male threads to enhance the seal. Carefully screw the fitting into the female connection, using a wrench to tighten it to the manufacturer’s specified torque. It is important to avoid over-tightening, which could damage the threads. Once installed, check for proper alignment and secure fit before operating the system.

Maintenance Tips

To ensure the longevity and optimal performance of the Male Union Elbow, regular maintenance is recommended. Inspect the fitting for signs of wear, corrosion, or leaks during routine checks. Clean the fitting and surrounding areas to remove any buildup that could affect performance. If removal is necessary for maintenance, apply thread lubricant to facilitate easier reinstallation and to protect the threads from damage.

Troubleshooting Common Issues

Common issues with the Male Union Elbow may include leaks or blockages. If a leak is detected, first ensure that the fitting is properly tightened. If the leak persists, inspect the threads for damage and replace the fitting if necessary. For blockages, check for debris within the fitting or connected lines and clean as required. Regular maintenance can help prevent these issues.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and fluid systems. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and expertise make it a trusted partner for commercial vehicle operators and manufacturers.

Cummins Male Union Elbow 4001987 in Engine Applications

The Cummins Male Union Elbow part number 4001987 is a critical component in the engine systems of various Cummins engines. This part is designed to connect different sections of the engine’s fuel, oil, or coolant lines, ensuring a secure and leak-proof connection. Its robust construction and precise fitment make it an essential part for maintaining the integrity and performance of the engine.

Application in QSK19 Engines

In the QSK19 engine series, the Male Union Elbow 4001987 is utilized in several configurations. These engines are known for their reliability and efficiency, often used in heavy-duty applications such as marine, construction, and power generation. The part’s role in these engines is to maintain the structural integrity of the fuel and coolant systems, ensuring that the engine operates smoothly under various conditions.

Application in CM500 Engines

The CM500 engine series also incorporates the Cummins Male Union Elbow 4001987 in its design. These engines are typically found in on-highway and vocational applications, where durability and performance are paramount. The part’s design ensures that the connections within the engine’s systems are both secure and resistant to the stresses of continuous operation.

Grouping of Applications

The Male Union Elbow 4001987 is not limited to specific models but is a versatile component used across multiple Cummins engine platforms. Its application in both the QSK19 and CM500 series highlights its importance in maintaining the functionality and longevity of these engines. The part’s compatibility with various engine configurations underscores its critical role in the overall engine assembly.

Role of Part 4001987 Male Union Elbow in Engine Systems

The part 4001987 Male Union Elbow is instrumental in several key engine systems, ensuring efficient and reliable operation.

In the accessories system, this component facilitates the connection between various accessory components, allowing for the smooth transfer of fluids or gases. Its design ensures a secure and leak-free connection, which is essential for the proper functioning of accessories such as pumps, filters, and regulators.

Within the fuel system, the Male Union Elbow plays a significant role in maintaining the integrity of fuel lines. It enables the connection of different sections of the fuel plumbing, ensuring that fuel is delivered consistently and without interruption to the engine. This is particularly important in high-performance engines where fuel delivery precision can affect engine performance and efficiency.

In fuel plumbing, the part 4001987 is often used to join sections of fuel lines, adapters, and fittings. Its robust construction handles the pressure and temperature variations common in fuel systems, contributing to the overall reliability and safety of the system.

For the hot start knock kit, the Male Union Elbow is used to connect components that help mitigate engine knocking during hot starts. This is achieved by ensuring that the necessary fluids or gases are routed correctly and efficiently, thereby enhancing the kit’s effectiveness in protecting the engine under demanding conditions.

Overall, the part 4001987 Male Union Elbow is a versatile and essential component in these engine systems, facilitating secure and efficient connections that are vital for optimal engine performance.

Conclusion

The Cummins Male Union Elbow (Part #4001987) is a vital component in the fluid systems of commercial trucks and various Cummins engines. Its robust construction, precise design, and ease of installation make it an essential part for maintaining the efficiency and reliability of these systems. Regular maintenance and proper installation procedures are key to ensuring the longevity and optimal performance of this fitting.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.