This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

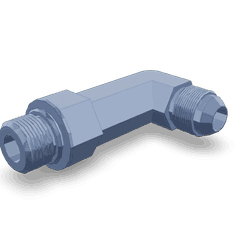

The Male Union Elbow, identified by Part #4065496, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the fluid systems of commercial trucks, facilitating efficient fluid flow and system connectivity.

Basic Concepts

A Male Union Elbow is a fitting used in fluid systems to connect and direct the flow of liquids or gases. It features a male threaded end that screws into a corresponding female fitting, allowing for secure connections. In the context of a truck’s system, it serves to join different sections of the fluid pathway, ensuring a continuous and controlled flow 1.

Purpose of the Male Union Elbow

The Male Union Elbow plays a role in the operation of a truck by directing fluid flow and connecting various components within the system. Its design allows for the redirection of fluid at an angle, which is particularly useful in navigating the complex layout of a truck’s fluid system. This fitting ensures that fluids, whether they are coolants, lubricants, or other necessary liquids, are efficiently transported to where they are needed 2.

Key Features

The Male Union Elbow is characterized by several key features that enhance its performance and durability. Its design includes a robust male threaded connection, which provides a secure fit and reduces the risk of leaks. The elbow’s material composition, typically a durable metal or high-grade plastic, ensures it can withstand the pressures and temperatures encountered in a truck’s fluid system. Additionally, the fitting may feature corrosion-resistant coatings or treatments to extend its service life in harsh operating environments 3.

Benefits

Utilizing a Male Union Elbow in truck systems offers several advantages. It improves fluid management by providing a reliable connection point that can handle changes in direction within the fluid pathway. The design of the elbow also facilitates easier installation and maintenance, as it allows for quick disconnection and reconnection without the need for complex tools or procedures. This ease of access is beneficial for routine checks and replacements, contributing to the overall efficiency of truck maintenance schedules.

Installation Process

Installing the Male Union Elbow requires careful attention to ensure a secure and leak-free connection. The process involves cleaning the mating surfaces to remove any debris or contaminants, applying the appropriate sealant or thread compound to the male threads, and then screwing the elbow into the female fitting until snug. It is important to use the correct tools to achieve the proper torque without over-tightening, which could damage the threads or the fitting itself. After installation, testing the connection under system pressure is recommended to verify its integrity.

Common Applications

The Male Union Elbow is commonly applied in various systems within commercial trucks, including but not limited to, the cooling system, fuel lines, and hydraulic systems. Its versatility makes it a valuable component for connecting and directing fluid flow in these critical systems, ensuring the truck operates efficiently and reliably.

Troubleshooting and Maintenance

Identifying common issues with the Male Union Elbow, such as leaks or blockages, involves regular inspection and monitoring of the fitting and its connections. Maintenance practices to ensure the longevity and optimal performance of the elbow include checking for signs of wear or corrosion, ensuring connections are tight and secure, and replacing the fitting if it shows signs of damage or failure. Routine maintenance not only helps prevent unexpected downtime but also contributes to the overall safety and efficiency of the truck’s operation.

Cummins Overview

Cummins, the manufacturer of the Male Union Elbow, has a long-standing reputation in the industry for quality and innovation. With a history of producing reliable automotive components, Cummins is committed to advancing technology and improving the performance of commercial vehicles. Their products are designed with durability and efficiency in mind, reflecting the company’s dedication to meeting the demanding requirements of the heavy-duty truck sector.

Compatibility of Male Union Elbow Part 4065496 with Cummins Engines

This part is designed to fit seamlessly into various Cummins engine configurations. It is crucial for ensuring proper fluid flow and maintaining the integrity of the engine’s cooling and exhaust systems.

QSK45 CM500 and QSK60 CM500

This part is compatible with both the QSK45 CM500 and QSK60 CM500 engines. These engines are part of Cummins’ QSK series, known for their robust performance and reliability in demanding applications. The part’s design ensures a secure connection, facilitating efficient fluid transfer and reducing the risk of leaks.

QSK60 CM850 MCRS and QSK60 G CM2358 K110

The QSK60 CM850 MCRS and QSK60 G CM2358 K110 engines also benefit from the use of this part. These engines are equipped with advanced features to enhance performance and efficiency. The part’s precision engineering ensures a perfect fit, contributing to the overall reliability and longevity of these engines.

QSK60G

The QSK60G engine is another model that can utilize this part. This engine is designed for high-performance applications, and the part’s compatibility ensures that it can handle the demands placed on it without compromising on fluid flow or structural integrity.

QSK78 CM500 and QSK95 CM2350 K110/K113

This part is also suitable for the QSK78 CM500 and QSK95 CM2350 K110/K113 engines. These engines are part of Cummins’ lineup of high-output, heavy-duty engines, and the part’s design ensures that it can withstand the rigors of these demanding applications. Its compatibility with these engines helps maintain optimal fluid flow and system integrity.

By ensuring a secure and efficient connection, this part plays a vital role in the performance and reliability of these Cummins engines.

Role of Part 4065496 Male Union Elbow in Engine Systems

The 4065496 Male Union Elbow is a component in various engine systems, facilitating the connection and efficient operation of several key elements.

In the arrangement of engine components, the Male Union Elbow ensures a secure and leak-proof connection between different sections of the plumbing. This is vital for maintaining the integrity of the system and ensuring that fluids, such as lubricants and coolants, are delivered without interruption.

Within the engine lubrication primer system, the Male Union Elbow plays a significant role. It connects the oil priming device kit to the engine, allowing for the initial lubrication of engine components before startup. This connection ensures that oil is evenly distributed, reducing wear and tear on moving parts.

In the context of the plumbing system, the Male Union Elbow is used to join pipes and fittings, enabling the smooth flow of fluids. Its design allows for easy disassembly and maintenance, which is beneficial during routine checks and repairs.

The engine oil primer relies on the Male Union Elbow to connect to the engine’s lubrication system. This connection is necessary for the primer to effectively circulate oil through the engine, ensuring all critical components are adequately lubricated.

Overall, the Male Union Elbow is a versatile component that enhances the functionality and reliability of engine systems by providing secure and efficient connections.

Conclusion

The 4065496 Male Union Elbow is a critical component in the fluid systems of commercial trucks and Cummins engines. Its design and features ensure secure connections, efficient fluid flow, and ease of maintenance. Regular inspection and maintenance of this part contribute to the overall efficiency, safety, and reliability of the truck’s operation.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.