4327748

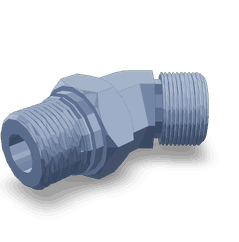

Male Union Elbow

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Male Union Elbow, identified by part number 4327748, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is integral to the fluid systems of commercial trucks, facilitating efficient operation and maintenance of the vehicle’s hydraulic and fuel systems.

Basic Concepts and Functionality

A Male Union Elbow is a fitting used in fluid systems to connect and direct the flow of liquids or gases between different components. It features a male threaded end that screws into a female fitting, allowing for secure connections. In commercial trucks, these elbows are commonly used in hydraulic, fuel, and coolant systems to manage fluid flow and ensure system integrity 1.

Purpose of the Male Union Elbow

This Cummins part plays a role in the truck’s fluid system by providing a connection point that allows for the redirection of fluid flow. It is designed to join different sections of the system, ensuring that fluids can move efficiently from one component to another. This part is crucial for maintaining the operational efficiency of the truck’s systems by ensuring that connections are secure and fluid flow is uninterrupted 2.

Key Features

The 4327748 Male Union Elbow is constructed from high-quality materials, typically brass or stainless steel, which offer excellent resistance to corrosion and wear. Its design includes a robust male threaded connection that ensures a tight seal, minimizing the risk of leaks. Additionally, the elbow’s angle allows for flexible routing of fluid lines, accommodating the complex layouts of commercial truck systems.

Benefits

Utilizing the 4327748 Male Union Elbow offers several advantages. Its durable construction and secure fitting design contribute to improved system efficiency and reliability. The ease of installation, thanks to its threaded connection, reduces downtime during maintenance procedures. Furthermore, its long-term reliability ensures that truck operators can depend on consistent performance, minimizing the need for frequent replacements 3.

Installation and Usage

Proper installation of the Male Union Elbow is vital for optimal performance. It should be screwed into the corresponding female fitting until snug, ensuring a secure connection without over-tightening, which could damage the threads. Before installation, it is advisable to apply a thread sealant to enhance the seal and prevent leaks. Integration within the truck’s fluid system requires careful planning to ensure that fluid lines are routed efficiently and securely.

Troubleshooting and Maintenance

Common issues with the Male Union Elbow may include leaks at the connection point or corrosion over time. Regular inspection for signs of wear or damage is recommended. If a leak is detected, tightening the connection or replacing the fitting may resolve the issue. Maintenance practices should include cleaning the fitting and applying thread sealant during reassembly to ensure a lasting seal.

Safety Considerations

When working with the Male Union Elbow, it is important to follow safety protocols. Ensure that the system is depressurized before attempting any maintenance or installation to avoid injury from fluid spray. Use the appropriate tools for tightening connections to prevent damage. Additionally, wear protective gear, such as gloves and safety glasses, to protect against potential hazards.

Cummins Overview

Cummins is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its commitment to producing high-quality components. With a strong reputation for reliability and performance, Cummins components are designed to meet the demanding requirements of commercial vehicles, ensuring that truck operators can rely on their equipment for efficient and safe operation.

Male Union Elbow (Part 4327748) in Cummins Engines

The Male Union Elbow, identified by the part number 4327748, is a critical component in the Cummins engine ecosystem. This part is designed to connect various sections of the engine’s piping system, ensuring a secure and leak-proof connection.

Application in Cummins Engines

-

QSK50 and CM2150 Engines: The Male Union Elbow is integral in the QSK50 and CM2150 engines, where it facilitates the connection between different sections of the exhaust and fuel systems. Its robust design ensures that it can withstand the high pressures and temperatures typical in these engines.

-

MCRS Engines: In the MCRS engines, the Male Union Elbow is used to connect the engine’s exhaust manifold to the turbocharger. This connection is vital for maintaining the efficiency and performance of the engine, as it ensures that exhaust gases are directed properly.

Importance of the Male Union Elbow

The Male Union Elbow is crucial for maintaining the integrity of the engine’s piping system. Its design allows for easy assembly and disassembly, which is essential during maintenance and repair operations. The use of high-quality materials ensures that the elbow can endure the harsh operating conditions within the engine.

Compatibility and Usage

The Male Union Elbow (4327748) is compatible with a range of Cummins engines, including but not limited to the QSK50, CM2150, and MCRS models. Its standardized design allows for easy integration into various engine configurations, making it a versatile component in the Cummins engine lineup.

Role of Part 4327748 Male Union Elbow in Engine Systems

The 4327748 Male Union Elbow is an essential component in various engine systems, facilitating the efficient transfer and regulation of fluids. Its role can be observed in the following systems:

Fuel Transfer Systems

In the Fuel Transfer Kit and the Fuel Transfer Right Hand Engine Kit, the 4327748 Male Union Elbow ensures a secure connection between different sections of the fuel lines. This connection is vital for maintaining the integrity of the fuel transfer process, allowing for consistent fuel delivery to the engine. The elbow’s design helps in managing the direction of fuel flow, reducing the risk of leaks and ensuring that fuel is delivered under the right conditions.

Pressure Regulation

When integrated with the Pressure Regulator Valve, the 4327748 Male Union Elbow assists in maintaining the desired pressure levels within the fuel system. This is achieved by connecting the valve to other components in the system, allowing for precise control over fuel pressure. The elbow’s robust construction ensures that it can withstand the pressures involved, contributing to the overall efficiency and reliability of the pressure regulation process.

Service and Maintenance

In the context of the Service Kit, the 4327748 Male Union Elbow plays a role in facilitating easier maintenance and servicing of the engine systems. By providing a reliable connection point, it allows mechanics to quickly disconnect and reconnect components during service procedures. This not only speeds up the maintenance process but also ensures that connections are secure and leak-free upon reassembly.

Overall Arrangement

The 4327748 Male Union Elbow contributes to the overall arrangement of engine components by enabling flexible and secure connections between various parts of the system. Its ability to change direction without compromising the flow of fluids makes it an invaluable component in the design and functionality of engine systems.

Conclusion

The 4327748 Male Union Elbow is a vital component in the fluid systems of commercial trucks and Cummins engines. Its robust design, durable materials, and secure fitting mechanism ensure efficient operation and maintenance of the vehicle’s hydraulic and fuel systems. Proper installation, regular maintenance, and adherence to safety protocols are essential for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.