This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

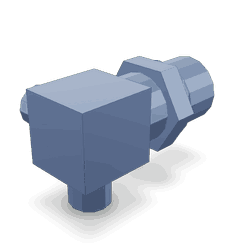

The 4380811 Male Union Elbow Fitting is a component designed for use in heavy-duty truck systems. It serves a specific function within various fluid systems, ensuring the efficient transfer of fluids such as fuel, hydraulic fluid, or coolant. Cummins, a well-established manufacturer in the automotive industry, produces this fitting, leveraging its expertise to deliver reliable and durable components for demanding applications.

Basic Concepts of Male Union Elbow Fittings

A Male Union Elbow Fitting is a type of pipe fitting used to join two pipes at a 90-degree angle. It features a male threaded end that connects to a female threaded component, allowing for easy assembly and disassembly. In the context of a truck’s hydraulic or fuel system, these fittings facilitate the redirection of fluid flow, accommodating the complex routing required in such systems.

Purpose and Role in Truck Operation

The 4380811 Male Union Elbow Fitting plays a role in the operation of a truck by providing a secure connection point within fluid systems. It is commonly used in fuel systems to connect fuel lines, in hydraulic systems for brake and steering components, and in coolant systems to manage the flow of coolant to and from the engine. Its design allows for efficient fluid transfer while withstanding the pressures and temperatures encountered in these systems.

Key Features

The 4380811 Male Union Elbow Fitting is characterized by several key features that enhance its functionality and durability. It is typically made from high-quality materials such as brass or stainless steel, which offer excellent resistance to corrosion and wear 1. The fitting features a male threaded connection, which ensures a tight seal when paired with a compatible female fitting. It is designed to handle specific pressure ratings, ensuring it can operate effectively under the conditions it is likely to encounter. Additionally, its design includes features that simplify installation and maintenance, such as easy-to-reach connection points and a robust construction that minimizes the risk of leaks.

Benefits

Using the 4380811 Male Union Elbow Fitting offers several benefits. It contributes to improved system efficiency by providing a secure and leak-free connection, which is vital for the reliable operation of fluid systems in heavy-duty trucks. The fitting’s design allows for straightforward installation, reducing downtime during maintenance procedures. Furthermore, its durable construction and resistance to corrosion mean that it requires minimal maintenance, offering long-term value to truck operators.

Installation Process

Installing the 4380811 Male Union Elbow Fitting involves several steps to ensure a secure and leak-free connection. Begin by gathering the necessary tools, including a wrench and Teflon tape. Prepare the fitting by applying Teflon tape to the male threaded end to enhance the seal. Connect the fitting to the corresponding female component, ensuring it is tightened to the manufacturer’s specified torque settings to avoid over-tightening, which could damage the threads. Finally, inspect the connection for any signs of leaks before putting the system into operation.

Troubleshooting Common Issues

Common issues with Male Union Elbow Fittings include leaks and corrosion. To address leaks, first, ensure that the fitting is properly tightened. If leaks persist, inspect the threads for damage and replace the fitting if necessary. Corrosion can be mitigated by selecting fittings made from corrosion-resistant materials and ensuring that the system is properly maintained to prevent the buildup of contaminants that can accelerate corrosion.

Maintenance Tips

Regular maintenance of the 4380811 Male Union Elbow Fitting is key to prolonging its lifespan. Inspect the fitting periodically for signs of wear, corrosion, or leaks. Clean the fitting and surrounding areas to remove any debris or contaminants that could affect its performance. If corrosion is detected, consider replacing the fitting to prevent further degradation. Following these maintenance practices will help ensure the fitting continues to perform reliably over time.

Cummins: Manufacturer Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company is committed to delivering reliable and efficient components that meet the demanding requirements of heavy-duty applications, underscoring its position as a trusted manufacturer in the market.

Male Union Elbow Fitting 4380811 in Cummins Engines

The Male Union Elbow Fitting 4380811, manufactured by Cummins, is a critical component in various Cummins engine models. This part is designed to facilitate the connection between different sections of the engine’s fuel, coolant, or oil systems, ensuring a secure and leak-free interface.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Male Union Elbow Fitting 4380811 is utilized to connect the engine’s fuel lines. This fitting ensures that the fuel flow remains uninterrupted and maintains the integrity of the fuel system. Its design allows for easy installation and removal, which is crucial during maintenance and repair operations.

MCRS Engines

For the MCRS engines, the Male Union Elbow Fitting 4380811 serves a similar purpose, connecting critical fluid lines within the engine. This fitting is essential for maintaining the operational efficiency of the engine by ensuring that fluid pathways are properly sealed and aligned. Its robust construction and precise fit are key to preventing leaks and ensuring the longevity of the engine components.

Grouping of Engines

The QSK60 and CM850 engines, both part of Cummins’ heavy-duty engine lineup, share common design philosophies and engineering principles. The Male Union Elbow Fitting 4380811 is a testament to the interchangeable and standardized components used across these models, facilitating easier maintenance and repair.

The MCRS engines, while part of a different series, also benefit from the use of standardized fittings like the 4380811. This standardization ensures that the same parts can be used across multiple engine models, reducing inventory costs and simplifying the supply chain.

Role of Part 4380811 Male Union Elbow Fitting in Engine Systems

The part 4380811 Male Union Elbow Fitting is integral to the efficient operation of various engine systems. In the context of an arrangement involving multiple fluid or gas pathways, this fitting serves as a pivotal connection point. It facilitates the smooth transition and redirection of fluids or gases between different components, ensuring that the flow is maintained without leaks or disruptions.

When integrated into the crankcase breather system, the Male Union Elbow Fitting plays a significant role in managing the ventilation of the crankcase. It connects the breather tube to the intake manifold or another suitable outlet, allowing the release of pressure built up within the crankcase. This is essential for maintaining optimal engine performance and preventing the accumulation of contaminants that could otherwise lead to engine wear or failure.

Conclusion

In summary, the 4380811 Male Union Elbow Fitting is a key component in ensuring the proper function and reliability of engine systems by providing secure and efficient connections between critical pathways. Its robust design, ease of installation, and maintenance benefits make it a valuable component in heavy-duty truck and engine applications.

-

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.