This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tube Connector Elbow 2880383 is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industry. This part is designed for use in commercial truck systems, where it serves a specific function within the vehicle’s infrastructure. Cummins is recognized for producing reliable and high-quality automotive components, and the 2880383 Tube Connector Elbow is no exception 1.

Basic Concepts

A Tube Connector Elbow is a fitting used in fluid systems to change the direction of flow within a pipeline. It is an essential element in ensuring that fluids, whether they be liquids or gases, can navigate through the various pathways required by the system’s design. In the context of a truck’s infrastructure, these elbows allow for the efficient routing of fluids to and from different components, ensuring that the system operates smoothly and effectively 2.

Role in Truck Operation

The 2880383 Tube Connector Elbow plays a specific role in the operation of a truck by facilitating the connection between different sections of tubing within the system. It is typically placed at points where a change in direction is necessary, such as when routing fluids around obstacles or when connecting to components that are not aligned with the primary flow path. This part supports various systems within the truck, including but not limited to, the fuel, coolant, and hydraulic systems, by providing a reliable connection that can withstand the pressures and temperatures associated with these applications 3.

Key Features

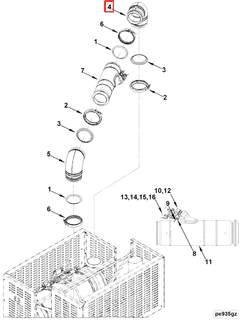

The 2880383 Tube Connector Elbow is characterized by several key features that enhance its functionality. It is constructed from durable materials that are resistant to corrosion and wear, ensuring a long service life even in demanding environments. The design of the elbow allows for easy installation and removal, which is beneficial during maintenance or repair procedures. Additionally, it may feature specific threading or sealing mechanisms that ensure a secure and leak-proof connection 4.

Benefits

The advantages provided by the 2880383 Tube Connector Elbow include improved system efficiency due to its precise fit and reliable performance. Its durable construction contributes to the overall longevity of the truck’s fluid systems, reducing the frequency of replacements and repairs. For fleet operators, this can translate into cost savings over time, as the need for maintenance is minimized 1.

Troubleshooting and Maintenance

Common issues that may arise with the 2880383 Tube Connector Elbow include leaks at the connection points or blockages within the elbow itself. Regular inspection and maintenance are recommended to ensure longevity and optimal performance. This may involve checking for signs of wear or corrosion, ensuring that connections are tight and secure, and replacing the elbow if any damage is detected. Troubleshooting tips include verifying that the elbow is the correct size and type for the application and ensuring that it is installed according to the manufacturer’s specifications 2.

Role in Exhaust Plumbing

The 2880383 Tube Connector Elbow is integral to the efficient operation of exhaust plumbing systems. This component facilitates the redirection of exhaust gases from the engine’s exhaust manifold to the catalytic converter and subsequently to the muffler and tailpipe.

In the exhaust system, the Tube Connector Elbow joins straight sections of exhaust tubing, allowing the system to navigate around other components and follow the vehicle’s chassis contours. This part ensures a secure and leak-free connection, which is essential for maintaining the system’s integrity and performance.

The Tube Connector Elbow also plays a role in managing thermal expansion. As exhaust gases heat up the tubing, the elbow allows for slight movement, preventing stress and potential failure of the joints. Additionally, it aids in reducing backpressure by providing a smooth transition between tubing sections, which enhances exhaust flow and overall engine efficiency 3.

About Cummins

Cummins is a manufacturer with a strong reputation in the industry for producing high-quality automotive components. They are committed to innovation and excellence, providing solutions that meet the demanding requirements of commercial and heavy-duty applications. Their products are designed with the end-user in mind, focusing on reliability, performance, and durability to ensure that they can withstand the rigors of daily use in various environments 4.

Conclusion

The 2880383 Tube Connector Elbow by Cummins is a vital component in the operation and maintenance of commercial truck systems. Its role in facilitating fluid flow, ensuring system efficiency, and contributing to the longevity of the truck’s infrastructure cannot be overstated. Regular maintenance and proper installation are key to maximizing the benefits of this Cummins part, ensuring that it continues to perform reliably in demanding applications.

-

Diesel Technology Fundamentals Service Repair Eighth Edition, Andrew Norman, The Goodheart-Willcox Company Inc, 2016

↩ ↩ -

Generalized Vehicle Dynamics, Daniel Williams, SAE International, 2022

↩ ↩ -

SAE International’s Dictionary of Testing, Verification and Validation, Jon M. Quigley, SAE International, 2023

↩ ↩ -

Light and Heavy Vehicle Technology, Fourth Edition, MJ Nunney, Butterworth-Heinemann, 2007

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.