This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

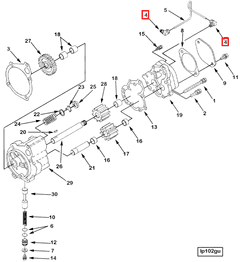

The Tube Connector Elbow 3254943, manufactured by Cummins, is a component designed for use in heavy-duty trucks. It serves a specific purpose within the fluid systems of these vehicles, facilitating the redirection of fluid flow. Tube connector elbows are integral to the efficient operation of fluid systems, ensuring that fluids are directed where needed without leakage or undue resistance 1.

Basic Concepts of Tube Connector Elbows

A tube connector elbow is a fitting used to change the direction of fluid flow within a system. It operates by providing a bend in the tubing, allowing fluids to navigate around obstacles or to reach different parts of the system. These elbows are typically manufactured from materials such as brass, stainless steel, or plastic, each offering distinct properties like corrosion resistance, durability, and ease of installation 2.

Role of the 3254943 Tube Connector Elbow in Truck Operation

This Cummins part plays a role in the fluid systems of heavy-duty trucks by enabling the redirection of fluid flow. This component is part of systems that require fluid to be transported in a specific path, such as cooling systems, hydraulic systems, or fuel lines. Its function contributes to the overall efficiency and reliability of the truck’s operation by ensuring that fluids reach their intended destinations without interruption 3.

Key Features of the 3254943 Tube Connector Elbow

The Tube Connector Elbow is characterized by its design, which includes a precise angle to facilitate smooth fluid transition. It is constructed from materials that offer durability and resistance to the specific fluids it carries. Unique attributes may include reinforced connections to prevent leaks, compatibility with a range of tubing sizes, and ease of integration into existing systems 4.

Benefits of Using the 3254943 Tube Connector Elbow

Incorporating this part into truck fluid systems offers several advantages. These include improved fluid flow due to its design, enhanced durability from its material construction, and ease of installation that minimizes downtime. Additionally, its design may contribute to reduced maintenance needs and longer service life.

Installation Considerations

Proper installation of this Cummins part involves adhering to specific torque settings to ensure secure connections without over-tightening, which could damage the fitting or the tubing. Alignment with other system components is crucial to maintain the intended fluid flow path. Compatibility with the existing system should be verified to prevent issues such as leaks or inefficient fluid transport.

Troubleshooting Common Issues

Common issues with tube connector elbows may include leaks, corrosion, or blockages. Troubleshooting steps involve inspecting the connections for proper torque and alignment, checking for signs of corrosion or material degradation, and ensuring that the fluid path is clear of obstructions. Addressing these issues promptly can prevent more significant problems within the fluid system.

Maintenance Tips

Regular maintenance of the 3254943 is recommended to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear or damage, cleaning to remove any buildup that could impede fluid flow, and considering replacement if the component shows significant degradation or if fluid system performance declines.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its wide range of products and commitment to quality and innovation. The company has a history of producing reliable and high-performance components, including the 3254943 Tube Connector Elbow, which reflects Cummins’ dedication to enhancing the efficiency and reliability of vehicle fluid systems.

Role of Part 3254943 Tube Connector Elbow in Engine Systems

The Tube Connector Elbow, identified by part number 3254943, is integral to the efficient operation of various engine systems. Its primary function is to facilitate the smooth transition of fluid flow at an angle, ensuring that the systems it connects operate without interruption.

Integration with Pressure Sensing Plumbing

In pressure sensing plumbing systems, the Tube Connector Elbow is used to redirect fluid pathways. This allows for the accurate measurement of pressure at various points within the engine. By providing a reliable connection point, it ensures that the pressure sensors receive consistent and uncontaminated fluid samples, which is essential for precise readings and effective engine management.

Application in Pump Systems

When incorporated into pump systems, the Tube Connector Elbow plays a significant role in maintaining the structural integrity of the plumbing. It allows for the necessary bends in the tubing without compromising the flow of fluids. This is particularly important in high-pressure environments where direct, straight connections could lead to stress points and potential leaks.

Function within Lubricating Oil Systems

In lubricating oil systems, the Tube Connector Elbow is employed to guide the flow of oil to various engine components that require lubrication. Its angled design helps in navigating around other engine parts, ensuring that oil reaches even the most inaccessible areas. This contributes to the overall efficiency and longevity of the engine by providing consistent lubrication to moving parts.

Conclusion

The Tube Connector Elbow, part 3254943, thus serves as a vital component in ensuring the seamless operation of engine systems by enabling fluid dynamics to be managed effectively across different applications. Its role in facilitating fluid flow, combined with its durability and ease of installation, makes it an essential part of heavy-duty truck fluid systems.

-

Barton, D. C., & Fieldhouse, J. D. (2009). Automotive Chassis Engineering: Powertrain Chassis System and Vehicle Body. Elsevier.

↩ -

Hillier, A. (2014). Fundamentals of Motor Vehicle Technology Book 1 6th Edition. Oxford University Press.

↩ -

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book: Powertrain. Springer.

↩ -

Pacejka, H. B. (2006). Tyre and Vehicle Dynamics. Butterworth-Heinemann.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.