This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

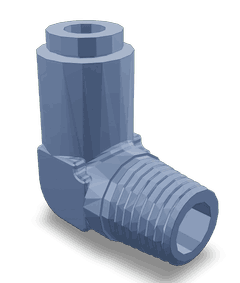

The Tube Connector Elbow 3283404, manufactured by Cummins, is a component designed for use in commercial trucks. It serves a specific function within the fluid systems of these vehicles. Tube connector elbows, in general, play a role in directing the flow of fluids by connecting different sections of tubing at an angle. This allows for efficient routing of fluids such as coolant, fuel, or hydraulic fluid within the truck’s systems 1.

Basic Concepts of Tube Connector Elbows

A tube connector elbow is a fitting used in fluid systems to join two sections of tubing at an angle. This design allows for changes in direction within the fluid pathway, accommodating the layout and space constraints within a vehicle. Proper fluid management is vital in heavy-duty trucks to ensure the efficient operation of engines, transmissions, and other systems that rely on fluid dynamics for cooling, lubrication, and power transmission 2.

Purpose of the 3283404 Tube Connector Elbow

The 3283404 Tube Connector Elbow is specifically designed to facilitate the connection between different sections of tubing in the fluid systems of a truck. By allowing a change in direction, it enables the fluid system to navigate around obstacles and fit within the confined spaces of a truck’s engine compartment. This part ensures a secure and leak-free connection, contributing to the overall efficiency of the fluid system.

Key Features

The 3283404 Tube Connector Elbow boasts several key features that enhance its functionality. It is constructed from durable materials, ensuring resistance to corrosion and wear. The design includes precise threading and sealing surfaces to provide a secure connection. Additionally, it may feature unique characteristics such as integrated gaskets or O-rings to improve sealing capabilities and facilitate easier installation.

Benefits

Utilizing the 3283404 Tube Connector Elbow offers several benefits. It improves fluid flow by providing a smooth transition between tubing sections, reducing the risk of turbulence and pressure loss. Its durable construction ensures long-term reliability, even under the demanding conditions found in commercial trucks. Furthermore, the design of the elbow allows for straightforward installation, minimizing downtime during maintenance procedures.

Installation Process

Installing the 3283404 Tube Connector Elbow involves several steps. First, ensure the tubing sections are clean and free of debris. Apply any necessary sealants to the threading of the elbow. Next, carefully thread the elbow onto the tubing sections, ensuring a snug fit without over-tightening, which could damage the threading. Tools such as wrenches may be required to secure the connection. Finally, inspect the connection for leaks and make any necessary adjustments.

Troubleshooting and Maintenance

Common issues with tube connector elbows include leaks, corrosion, and blockages. Regular inspection and maintenance can help identify these problems early. To maintain the 3283404 Tube Connector Elbow, check for signs of wear or damage, such as cracks or corrosion, and replace the part if necessary. Keeping the connections clean and free of debris will also contribute to the longevity and optimal performance of the elbow.

Cummins: Manufacturer Overview

Cummins is a well-established manufacturer with a rich history in the production of diesel engines and components. Known for its expertise and innovation, Cummins has earned a reputation for quality and reliability in the commercial truck industry. The company’s commitment to quality is evident in its rigorous testing and manufacturing processes, ensuring that components like the 3283404 Tube Connector Elbow meet the high standards required for use in heavy-duty applications 3.

Cummins Tube Connector Elbow 3283404

The Cummins Tube Connector Elbow 3283404 is a critical component in the engine systems of various Cummins engines, including the 6B5.9. This part is designed to facilitate the smooth transfer of fluids, gases, or other substances within the engine’s internal pathways. Its primary function is to connect different sections of tubing, ensuring that the flow remains uninterrupted and efficient.

In the context of the 6B5.9 engine, the Tube Connector Elbow 3283404 is strategically placed to manage the routing of fluids or gases, contributing to the overall performance and reliability of the engine. The design of this elbow allows for precise angles and connections, which are essential for maintaining the integrity of the engine’s fluid dynamics.

While the specific applications of the Tube Connector Elbow 3283404 may vary across different engine models, its importance remains consistent. This part is integral to the engine’s operation, ensuring that all connected systems function as intended. The precision engineering of this component underscores Cummins’ commitment to quality and durability in their engine parts.

Role of Part 3283404 Tube Connector Elbow in Air Compressor Systems

In air compressor systems, the Tube Connector Elbow (part 3283404) serves as a pivotal component that facilitates the redirection of airflow within the system. This part is integral in connecting various sections of the air tubing, ensuring a seamless transition and maintaining the efficiency of the air flow.

When integrated into an air compressor setup, the Tube Connector Elbow allows for the connection between straight sections of tubing, enabling the system to navigate around obstacles or change direction as needed. This is particularly important in complex systems where space optimization and efficient routing of air lines are essential.

The Tube Connector Elbow works in conjunction with other components such as the air filter, compressor pump, and pressure regulator. By providing a smooth transition in the tubing path, it helps in reducing turbulence and potential pressure drops that could otherwise affect the performance of the compressor.

Additionally, this component is often used in conjunction with quick-connect fittings and hose clamps to ensure secure and leak-free connections. Its role becomes even more significant in systems where maintenance and quick adjustments are required, as it allows for easier disassembly and reassembly of the air lines.

Conclusion

In summary, the Tube Connector Elbow (part 3283404) plays a key role in the overall functionality and efficiency of air compressor systems by ensuring proper airflow management and facilitating easy maintenance. Its design and construction contribute to the reliability and performance of both engine and air compressor systems in commercial trucks.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.