This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3285751 Tube Connector Elbow is a specialized component designed for use in commercial trucks. It plays a role in the fluid systems of these vehicles, ensuring the efficient transfer of fluids such as fuel, air, or other substances 1. Cummins Inc., the manufacturer of this part, is renowned in the automotive industry for its commitment to quality and innovation. With a long-standing reputation for producing reliable and high-performance parts, Cummins continues to be a trusted name among fleet operators and maintenance professionals.

Basic Concepts of Tube Connector Elbows

A Tube Connector Elbow is a fitting used in fluid systems to change the direction of flow within a pipeline. It is typically employed where a change in direction is necessary to accommodate the layout of the system or to connect different sections of tubing. In the context of a truck’s various systems, these elbows facilitate the routing of fluids, ensuring that they reach their intended destinations without obstruction. They are integral to maintaining the integrity and efficiency of the fluid pathways within the vehicle 2.

Purpose of the 3285751 Tube Connector Elbow

The Cummins 3285751 Tube Connector Elbow is specifically designed to play a role in the fluid systems of commercial trucks. It is utilized in applications where a 90-degree change in direction is required, such as in fuel lines, air intake systems, or other fluid transport pathways. By providing a smooth transition between sections of tubing, this elbow helps to maintain consistent fluid flow, reducing the risk of leaks or disruptions that could affect the performance of the truck.

Key Features

The Cummins 3285751 Tube Connector Elbow boasts several key features that enhance its functionality. It is constructed from high-quality materials that offer resistance to corrosion and wear, ensuring durability in the demanding environment of a commercial truck. The design of the elbow includes precise machining to ensure a tight fit with compatible tubing, which is crucial for preventing leaks. Additionally, the elbow may feature unique characteristics such as reinforced walls or specialized coatings to further improve its performance and longevity.

Benefits

Utilizing the Cummins 3285751 Tube Connector Elbow in a truck’s fluid systems can lead to several benefits. The part contributes to improved system efficiency by ensuring a smooth and uninterrupted flow of fluids. Its robust construction and design attributes enhance the durability and reliability of the fluid pathways, which can lead to reduced maintenance needs and increased uptime for the vehicle. Furthermore, the use of high-quality components like this elbow can contribute to the overall performance and longevity of the truck.

Installation Considerations

Proper installation of the Cummins 3285751 Tube Connector Elbow is important to ensure its effective operation. It is recommended to follow the manufacturer’s guidelines for installation, which may include the use of specific tools or procedures. Careful attention should be paid to ensuring a secure and leak-free connection between the elbow and the tubing. This may involve the use of appropriate sealants or tightening techniques to achieve the desired fit.

Troubleshooting Common Issues

Common issues with Tube Connector Elbows can include leaks, blockages, or damage due to wear or corrosion. To address these problems, it is important to conduct a thorough inspection of the elbow and the surrounding tubing. If a leak is detected, the connection points should be re-sealed or tightened as necessary. Blockages may require disassembly and cleaning of the elbow to restore proper fluid flow. In cases of significant damage, replacement of the elbow may be necessary to maintain system integrity.

Maintenance Tips

Regular maintenance of the Cummins 3285751 Tube Connector Elbow is important to ensure its longevity and optimal performance. This includes periodic inspection for signs of wear, corrosion, or leaks. Cleaning the elbow as part of routine system maintenance can help to prevent buildup that may impede fluid flow. Additionally, ensuring that all connections are secure and free from leaks will contribute to the reliable operation of the truck’s fluid systems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration systems, and related components. With a history spanning over a century, Cummins has established itself as a leader in the industry, known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range serves various markets, including commercial vehicles, construction, agriculture, and power generation, among others. Cummins’ dedication to advancing technology and improving the efficiency and reliability of its products has solidified its position as a trusted partner in the automotive industry.

Cummins Tube Connector Elbow 3285751 Compatibility

The Cummins Tube Connector Elbow part number 3285751 is designed to fit seamlessly with a variety of Cummins engines, ensuring optimal performance and durability. This part is integral to the engine’s cooling system, facilitating the proper flow of coolant and maintaining the engine’s operational temperature.

QSN14 Engines

The Tube Connector Elbow 3285751 is specifically engineered to integrate with the QSN14 engines. These engines are known for their robust construction and are often utilized in heavy-duty applications. The part’s precision fit ensures that it can withstand the high pressures and temperatures typical of these engines, contributing to their longevity and efficiency.

CM876 Engines

Similarly, the Tube Connector Elbow 3285751 is compatible with the CM876 engines. These engines are designed for medium-duty applications and are recognized for their reliability and performance. The part’s design allows for a secure connection, preventing leaks and ensuring that the engine operates smoothly.

N103 Engines

The N103 engines also benefit from the use of the Tube Connector Elbow 3285751. These engines are typically used in a variety of applications, from construction to agricultural use. The part’s compatibility with these engines ensures that it can handle the diverse operating conditions these engines encounter, providing a reliable and efficient solution.

Grouping of Engines

The Tube Connector Elbow 3285751 is versatile enough to fit across different engine groups within the Cummins lineup. Whether it’s the heavy-duty QSN14, the medium-duty CM876, or the versatile N103, this part is designed to meet the specific needs of each engine type, ensuring that it performs optimally in any application.

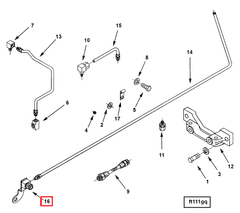

Role of Part 3285751 Tube Connector Elbow in Fuel Plumbing Systems

In fuel plumbing systems, the Tube Connector Elbow (part 3285751) serves as a pivotal component facilitating the transition and redirection of fuel flow within the engine system. This component is integral in connecting various sections of the fuel lines, ensuring a seamless and efficient transfer of fuel from the tank to the engine.

Integration with Fuel Lines

The Tube Connector Elbow is typically installed at junctures where the fuel lines need to change direction. Its design allows for a smooth bend in the fuel path, minimizing the risk of fuel line stress or damage. This is particularly important in high-performance engines where fuel lines are subjected to significant pressure and vibration.

Connection to Fuel Filter

In many engine systems, the Tube Connector Elbow is used to link the fuel lines to the fuel filter. This connection ensures that fuel passes through the filter efficiently, removing contaminants before reaching the engine. Proper alignment and secure fitting at this juncture are essential for maintaining fuel purity and engine performance.

Link to Fuel Injectors

Further along the fuel path, the Tube Connector Elbow plays a role in connecting the filtered fuel line to the fuel injectors. This ensures that the fuel is delivered precisely where needed within the engine, contributing to optimal combustion and engine efficiency. The elbow’s design helps in managing the spatial constraints often found in engine compartments.

Role in Fuel Return Lines

In systems with fuel return lines, the Tube Connector Elbow is also utilized to direct excess fuel back to the tank. This helps in maintaining the correct fuel pressure within the system, ensuring consistent engine performance across varying operational conditions.

Contribution to System Integrity

By providing reliable connections at critical points in the fuel plumbing, the Tube Connector Elbow contributes to the overall integrity and efficiency of the fuel system. Its proper installation and maintenance are key to preventing fuel leaks, ensuring safe and efficient engine operation.

Conclusion

The Cummins 3285751 Tube Connector Elbow is a critical component in the fluid systems of commercial trucks, ensuring efficient fluid transfer and maintaining system integrity. Its robust construction, precise design, and compatibility with various Cummins engines make it a reliable choice for fleet operators and maintenance professionals. Proper installation, regular maintenance, and timely troubleshooting are essential to maximize the performance and longevity of this part, contributing to the overall efficiency and reliability of the vehicle.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.