This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

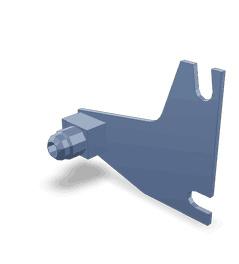

The Tube Connector Elbow, part number 3401167, manufactured by Cummins, is a component designed for use in commercial trucks. It serves a specific function within the fluid systems of these vehicles. Tube connector elbows, in general, play a role in redirecting fluid flow within systems, ensuring efficient operation and maintenance of various truck functions. This part is no exception, contributing to the overall performance and reliability of commercial trucks.

Basic Concepts of Tube Connector Elbows

Tube connector elbows are fittings used in fluid systems to change the direction of fluid flow. They are integral in maintaining the integrity and efficiency of fluid pathways within a vehicle. These components are typically constructed from materials such as brass, stainless steel, or plastic, chosen for their durability, resistance to corrosion, and ability to withstand high pressures. The material selection is significant as it directly impacts the connector’s performance and longevity in demanding environments 1.

Purpose of the 3401167 Tube Connector Elbow in Truck Operations

The 3401167 Tube Connector Elbow is specifically designed to facilitate the redirection of fluid flow in commercial trucks. It is commonly integrated into fluid systems such as fuel, hydraulic, or coolant systems. By enabling a change in the direction of fluid flow, this component helps in the efficient distribution of fluids throughout the truck, supporting various operational functions and ensuring the system’s overall effectiveness 2.

Key Features of the 3401167 Tube Connector Elbow

The 3401167 Tube Connector Elbow is characterized by its robust design and construction, featuring connection types that ensure secure and leak-free attachments. It is made from materials that offer high durability and resistance to the pressures and temperatures encountered in truck fluid systems. Unique design elements may include reinforced connection points or specialized coatings that enhance its performance and durability in challenging conditions 3.

Benefits of Using the 3401167 Tube Connector Elbow

Utilizing the 3401167 Tube Connector Elbow offers several advantages. It contributes to improved fluid flow efficiency within the system, ensuring that fluids are distributed effectively throughout the truck. Its durability under high pressure conditions makes it a reliable component for long-term use. Additionally, the design of this connector allows for ease of installation, reducing downtime during maintenance procedures. These benefits collectively enhance the overall performance and reliability of the truck.

Installation and Integration

Proper installation of the 3401167 Tube Connector Elbow is vital for its optimal performance. It should be integrated into the truck’s fluid system with attention to compatibility with other components and systems. Correct installation ensures that the connector functions as intended, maintaining the efficiency and reliability of the fluid system. Guidelines for installation should be followed to avoid common pitfalls that could lead to inefficiencies or failures.

Troubleshooting and Maintenance

Common issues with tube connector elbows can include leaks, blockages, or corrosion. Regular inspection and maintenance are recommended to identify these issues early and address them promptly. Maintenance tips for the 3401167 Tube Connector Elbow include checking for signs of wear or damage, ensuring connections are secure, and replacing the component when necessary to maintain system efficiency and safety.

Cummins: Manufacturer Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to quality, innovation, and customer satisfaction. The company has a history of producing reliable and high-performance automotive components, including the 3401167 Tube Connector Elbow. Cummins’ dedication to excellence in manufacturing ensures that their products meet the demanding requirements of commercial truck operations.

Role of Part 3401167 Tube Connector Elbow in Fuel Plumbing Systems

The Tube Connector Elbow, identified by part number 3401167, is a component in the fuel plumbing systems of various engine setups. Its primary function is to facilitate the redirection of fuel lines within the engine compartment, ensuring a smooth and efficient flow of fuel from the tank to the engine.

In fuel plumbing, the Tube Connector Elbow is often positioned at junctions where the fuel line needs to change direction. This part allows the fuel lines to navigate around other components, such as the engine block, transmission, and exhaust system, without kinking or stressing the lines.

When integrated into the fuel return system, the Tube Connector Elbow helps manage the flow of excess fuel back to the tank, maintaining consistent fuel pressure within the system. In fuel injection systems, it ensures that the fuel injectors receive a steady supply of fuel, which is vital for precise fuel delivery and engine performance.

Additionally, the Tube Connector Elbow plays a role in the fuel filter bypass system. It allows fuel to flow around the filter when necessary, ensuring that the engine continues to operate smoothly even if the filter becomes clogged.

Overall, the Tube Connector Elbow is a versatile component that enhances the reliability and efficiency of fuel plumbing systems in engine applications.

Conclusion

The 3401167 Tube Connector Elbow by Cummins is a vital component in the fluid systems of commercial trucks, ensuring efficient fluid flow and system reliability. Its robust design, ease of installation, and maintenance benefits make it a preferred choice for truck manufacturers and operators alike. Regular maintenance and proper installation are key to maximizing the performance and longevity of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.