This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

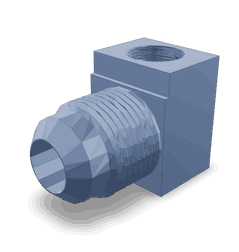

The Tube Connector Elbow 3401518, manufactured by Cummins, is a specialized component designed for use in commercial trucks. This part serves a specific function within the truck’s system, contributing to the overall efficiency and performance of the vehicle. Cummins, a well-established name in the industry, produces this component with a focus on reliability and durability, ensuring it meets the demanding requirements of commercial truck operations 1.

Basic Concepts and Functionality

A Tube Connector Elbow is a fitting used to join two tubes at an angle, facilitating the redirection of fluid or gas flow within a system. The 3401518 model operates on this principle, designed to connect and redirect hoses or pipes in the truck’s system. Its design allows for a secure and leak-proof connection, ensuring the efficient transfer of fluids or gases without loss or contamination. The functionality of the Tube Connector Elbow is based on its ability to provide a stable and durable connection point, which is crucial for the operation of various systems within a truck 1.

Purpose and Role in Truck Operation

This Cummins part plays a role in the truck’s system by enabling the connection of hoses or pipes at an angle, which is often necessary to navigate the complex layout of a truck’s engine compartment. This component contributes to the efficiency and performance of the truck by ensuring that fluids or gases are directed correctly throughout the system. Its proper function is vital for maintaining the integrity of the system it is a part of, whether it be for coolant, fuel, or other critical fluids 1.

Key Features

The 3401518 is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials, ensuring resistance to corrosion and wear. The design includes precise threading and sealing surfaces to provide a secure connection. Additionally, the elbow’s angle is specifically engineered to fit the requirements of commercial truck systems, offering both flexibility and strength in its application 1.

Benefits

Utilizing this part in truck systems offers several benefits. Its durable construction and precise design contribute to improved system performance and reliability. The component’s ability to provide a secure and leak-proof connection enhances the efficiency of fluid or gas transfer within the truck. Furthermore, the longevity and reliability of the 3401518 can offer cost-effectiveness by reducing the need for frequent replacements or repairs 1.

Installation and Compatibility

When installing the 3401518, it is important to follow manufacturer guidelines to ensure a proper fit and function. Compatibility with various truck models and systems is a consideration, as the elbow must match the specific requirements of the truck’s system it is intended for. Proper installation involves ensuring the connector is securely fastened and that all connections are tight to prevent leaks 1.

Maintenance and Troubleshooting

Maintaining the 3401518 involves regular inspection for signs of wear or damage. Common issues may include leaks at the connection points or corrosion on the fitting. Troubleshooting these issues often involves tightening connections or, in more severe cases, replacing the fitting. Preventive maintenance practices, such as cleaning the fitting and inspecting for damage during routine checks, can help ensure the longevity and optimal performance of the component 1.

Cummins: Manufacturer Overview

Cummins is a renowned manufacturer in the commercial truck industry, known for its high-quality engines and components. With a history of innovation and reliability, Cummins has established a strong reputation for producing durable and efficient parts. Their range of products for commercial trucks includes engines, filtration systems, and various components designed to enhance the performance and reliability of trucks. Cummins’ commitment to quality and customer satisfaction is evident in their extensive product line and the trust they have earned within the industry 1.

Tube Connector Elbow (Part 3401518) in Cummins Engines

The Tube Connector Elbow, identified by the part number 3401518, is a critical component in the Cummins engine family. This part is integral to the proper functioning of the engine’s cooling system, ensuring efficient heat transfer and maintaining optimal engine performance.

M11 CELECT and M11 CELECT PLUS

In the M11 CELECT and M11 CELECT PLUS engines, the Tube Connector Elbow is designed to connect the coolant passages within the engine block. This connection is vital for routing coolant through the engine, facilitating the dissipation of heat generated during operation. The precision engineering of the Tube Connector Elbow ensures a secure and leak-free connection, which is essential for maintaining the engine’s thermal efficiency 1.

QSM11 CM570

The QSM11 CM570 engine also utilizes the Tube Connector Elbow (part 3401518) to manage the coolant flow within its complex system. This engine, known for its robust performance and reliability, requires precise components to handle the high pressures and temperatures it operates under. The Tube Connector Elbow in this engine model is engineered to withstand these demanding conditions, ensuring longevity and consistent performance 1.

Grouping of Engines

The Tube Connector Elbow (part 3401518) is a shared component across the M11 CELECT, M11 CELECT PLUS, and QSM11 CM570 engines. This commonality highlights the importance of this part in the overall design and functionality of these engines. By using a standardized part, Cummins ensures that these engines benefit from a reliable and well-engineered component that is integral to their cooling systems 1.

Role of Part 3401518 Tube Connector Elbow in Fuel Plumbing Systems

In fuel plumbing systems, the Tube Connector Elbow (part 3401518) serves as a pivotal component that facilitates the redirection of fuel lines. This part is integral in maintaining the structural integrity and efficiency of the fuel delivery system.

When integrated into the fuel plumbing, the Tube Connector Elbow allows for a smooth transition between different sections of the fuel line, accommodating the necessary bends and turns required to navigate around other engine components. This is particularly important in compact engine bays where space is at a premium.

The Tube Connector Elbow also plays a role in reducing stress on the fuel lines. By providing a gradual change in direction, it minimizes the risk of kinking or abrasion, which can lead to fuel leaks or reduced fuel flow. This is essential for maintaining consistent fuel pressure and ensuring that the engine receives a steady supply of fuel 2.

Furthermore, the use of the Tube Connector Elbow in fuel plumbing systems contributes to the overall safety and reliability of the engine. It helps in securing the fuel lines in place, preventing them from coming loose or vibrating excessively, which could otherwise result in fuel system failures 2.

Conclusion

In summary, the Tube Connector Elbow is a key component in both the cooling and fuel plumbing systems of commercial trucks, enhancing the functionality and durability of these critical systems. Its role in maintaining efficient fluid and gas transfer, along with its durability and reliability, makes it an essential part for the operation of Cummins engines and other commercial truck systems 12.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.