This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

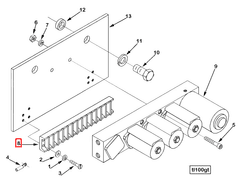

The 218901 Terminal Block, manufactured by Cummins, is a component designed for use in heavy-duty truck electrical systems. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces this terminal block to enhance the efficiency and reliability of electrical connections in trucks. This Cummins part is significant for maintaining the integrity of electrical systems, ensuring that power and signals are effectively managed and distributed throughout the vehicle.

Basic Concepts of Terminal Blocks

Terminal blocks are devices used in electrical systems to connect and distribute electrical power and signals. They provide a secure and organized method for wiring, allowing multiple wires to be connected to a single point. Terminal blocks facilitate easy access for maintenance and troubleshooting, and they help prevent electrical faults by ensuring that connections are stable and reliable. In the context of heavy-duty trucks, terminal blocks play a vital role in managing the complex electrical systems that power various components and systems within the vehicle 1.

Purpose of the 218901 Terminal Block in Truck Operations

The 218901 Terminal Block is specifically designed to manage and distribute electrical connections within the electrical system of a heavy-duty truck. It serves as a central point for connecting various electrical wires and cables, ensuring that power and signals are efficiently routed to their intended destinations. By centralizing these connections, the terminal block helps maintain a tidy and organized electrical system, which is crucial for the proper functioning of the truck’s electrical components 2.

Key Features of the 218901 Terminal Block

The 218901 Terminal Block is constructed with high-quality materials to ensure durability and reliability. Its design includes features such as corrosion-resistant coatings and robust connection points that can withstand the harsh conditions typical of heavy-duty truck operations. The terminal block supports various connection types, allowing for versatile integration within different electrical systems. Additionally, its unique attributes, such as easy-to-use clamping mechanisms and clear labeling, enhance both performance and user-friendliness.

Benefits of Using the 218901 Terminal Block

Utilizing the 218901 Terminal Block offers several advantages. It improves electrical management by providing a centralized and organized connection point, which simplifies the routing of wires and reduces the risk of electrical faults. The terminal block also facilitates ease of maintenance, as its design allows for quick access to connections, making inspections and repairs more straightforward. Furthermore, its reliability in harsh operating conditions ensures that the electrical system remains functional and efficient, even under demanding circumstances 3.

Installation and Integration

Proper installation and integration of the 218901 Terminal Block within a truck’s electrical system are crucial for its effective performance. Best practices include ensuring that all connections are secure and properly tightened, following the manufacturer’s guidelines for placement and wiring. It is also important to consider the environmental conditions the terminal block will be exposed to, such as vibrations and temperature fluctuations, to ensure long-term reliability. Potential challenges during installation may include ensuring compatibility with existing electrical components and systems.

Troubleshooting Common Issues

Common issues associated with the 218901 Terminal Block can include loose connections, corrosion, and electrical faults. To address these problems, it is important to regularly inspect the terminal block for signs of wear or damage. Loose connections can be tightened, and corroded terminals can be cleaned using appropriate solutions. Electrical faults may require more detailed diagnosis to identify the source of the problem, which could involve testing the continuity of connections or checking for damaged wires.

Maintenance Tips

Regular maintenance of the 218901 Terminal Block is essential for ensuring its longevity and optimal performance. Maintenance practices should include periodic cleaning of the terminal block to remove any dirt or debris that could affect connections. Inspecting the terminals for signs of corrosion or wear is also important, as is testing the electrical connections for continuity and proper function. Following these maintenance tips will help prevent issues and ensure that the terminal block continues to perform reliably.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the automotive and heavy-duty truck industry for producing high-quality, reliable components. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of various industries. Cummins’ commitment to innovation and customer satisfaction has made it a trusted name in the industry.

Cummins Terminal Block 218901 in Engine Applications

The Cummins Terminal Block 218901 is a critical component in the electrical systems of various Cummins engines. This part is designed to facilitate the connection of electrical wires, ensuring a secure and reliable interface for power and signal transmission.

K19 Engine Series

In the K19 engine series, the Terminal Block 218901 plays a vital role in managing the electrical connections for the engine’s control systems. This series of engines is known for its robust design and efficiency, often used in heavy-duty applications. The terminal block ensures that all electrical connections are properly insulated and secured, which is crucial for the engine’s performance and longevity.

Grouping of Applications

The Terminal Block 218901 is not limited to the K19 series alone. It is also utilized in other Cummins engine groups where reliable electrical connections are paramount. This includes various industrial and commercial engines where consistent power delivery and signal integrity are essential.

Each application of the Terminal Block 218901 is tailored to meet the specific electrical requirements of the engine it supports, ensuring compatibility and optimal performance across different engine models.

Role of Part 218901 Terminal Block in Engine Systems

The Terminal Block, identified as part 218901, serves as a pivotal junction point within the engine’s electrical and control systems. It facilitates the organized distribution and management of electrical connections essential for the operation of various engine components.

Integration with Electrical and Control Systems

-

Electrical Control Panel (ECP): The Terminal Block interfaces directly with the ECP, allowing for the secure and efficient transfer of electrical signals. This connection is vital for the ECP to monitor and regulate engine performance parameters.

-

Engine Wiring: It acts as a central hub for the engine wiring, ensuring that all electrical cables are properly connected and organized. This setup minimizes the risk of electrical faults and enhances the reliability of the engine’s electrical system.

Fuel and Throttle Systems

-

Fuel Tubing: Although primarily mechanical, the fuel system relies on electrical signals for precise control. The Terminal Block provides the necessary connections for sensors and actuators within the fuel tubing system, enabling accurate fuel delivery.

-

Instrument Panel: Connections to the instrument panel allow for the display of engine diagnostics and performance metrics. The Terminal Block ensures that all relevant data is accurately transmitted from the engine to the panel.

-

Throttle Lever and Throttle Control: The Terminal Block plays a key role in the throttle system by providing electrical connections for the throttle lever and throttle control. This ensures that throttle adjustments are smoothly and accurately translated into engine performance changes.

Multi-Unit Throttle Control

- Multi-Unit Throttle Control (MUTC): In systems with multiple engines, the Terminal Block facilitates the interconnection of throttle controls. This allows for synchronized operation and precise management of engine performance across all units.

Terminal and Term MTG

- Terminal and Term MTG: These components rely on the Terminal Block for secure and stable electrical connections. The Terminal Block ensures that all terminals are correctly aligned and connected, reducing the likelihood of disconnections or poor contacts.

Conclusion

In summary, the Terminal Block (part 218901) is integral to the functioning of the engine’s electrical and control systems. It ensures that all components, from the electrical control panel to the throttle systems, are accurately and reliably interconnected.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.