This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

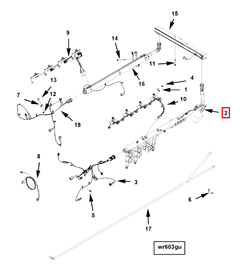

The 2871206 Electronic Control Module (ECM) Wiring Harness is a vital component in the electrical system of commercial trucks. It facilitates communication between the ECM and various sensors and actuators throughout the vehicle. This harness ensures that the ECM receives accurate data and can effectively control the truck’s systems, contributing to overall performance and reliability 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to other electronic components within the truck. It consists of multiple wires, each serving a specific function, bundled together for protection and organization. The harness plays a role in transmitting signals and power between the ECM and components such as sensors, actuators, and other control units. This ensures that the ECM can monitor and adjust the truck’s operations in real-time 2.

Role of the 2871206 Electronic Control Module Wiring Harness in Truck Operation

The 2871206 ECM Wiring Harness is integral to the operation of a commercial truck. It enables the ECM to interact with various systems, including the engine, transmission, brakes, and emissions control. By providing a reliable pathway for data and power, the harness ensures that the ECM can make precise adjustments to these systems, optimizing performance and efficiency. Additionally, it plays a role in diagnostic processes by allowing the ECM to receive feedback from sensors, which aids in identifying and addressing issues promptly 3.

Key Features of the 2871206 Electronic Control Module Wiring Harness

The 2871206 ECM Wiring Harness is designed with several key features to enhance its functionality and durability. These include robust construction to withstand the harsh environments typical of commercial trucking, precise engineering to ensure accurate signal transmission, and compatibility with a wide range of truck models. The harness is also designed for easy integration with existing systems, minimizing installation complexity and downtime 4.

Benefits of Using the 2871206 Electronic Control Module Wiring Harness

Utilizing the 2871206 ECM Wiring Harness offers several benefits. It contributes to improved truck performance by ensuring that the ECM receives accurate data and can make timely adjustments. The harness enhances reliability by providing a durable and secure connection between the ECM and other components. Additionally, it supports efficiency by enabling precise control of various systems, which can lead to fuel savings and reduced maintenance costs 5.

Installation Considerations

When installing the 2871206 ECM Wiring Harness, it is important to follow guidelines and best practices to ensure proper functionality. This includes verifying that the truck’s electrical system is compatible with the harness, using the appropriate tools for installation, and ensuring that all connections are secure and correctly routed. It may also be necessary to consult the truck’s service manual for specific instructions related to the model 6.

Troubleshooting Common Issues

Identifying and resolving common problems with the 2871206 ECM Wiring Harness involves several steps. Begin by checking for visible signs of damage, such as frayed wires or loose connections. Use diagnostic tools to test the harness for continuity and signal integrity. If issues are detected, they can often be resolved by repairing or replacing damaged sections of the harness. Regular inspections and maintenance can help prevent many common problems 7.

Maintenance Tips

To ensure the longevity and optimal performance of the 2871206 ECM Wiring Harness, regular maintenance is recommended. This includes inspecting the harness for signs of wear or damage, ensuring that all connections are secure, and protecting the harness from physical damage and environmental factors. Additionally, keeping the harness clean and free from debris can help maintain its functionality 8.

Safety Precautions

When working with the 2871206 ECM Wiring Harness, it is important to observe several safety measures. This includes ensuring that the truck’s electrical system is de-energized before beginning any work to prevent electrical shocks. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow proper handling procedures to avoid damaging the harness or other components 9.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance components. The company’s commitment to innovation and quality has made it a trusted name among fleet operators and maintenance professionals 10.

Cummins Engine Compatibility with Part 2871206

The Electronic Control Module (ECM) Wiring Harness, part number 2871206, is a critical component in the electrical system of various Cummins engines. This wiring harness is designed to ensure seamless communication between the ECM and other electronic control units within the engine’s system.

QSK60 and CM850 Engines

The QSK60 and CM850 engines, both high-performance models, are often used in heavy-duty applications such as marine and industrial settings. The ECM Wiring Harness for these engines is engineered to handle the complex electrical demands of these high-output engines. It ensures that the ECM can effectively manage engine performance, fuel injection, and emissions control, providing reliability and efficiency in demanding environments 11.

MCRS Engines

The MCRS (Marine Common Rail System) engines are another series where the ECM Wiring Harness plays a vital role. These engines are designed for marine applications, requiring robust and reliable electrical connections to withstand the harsh conditions of marine environments. The wiring harness for MCRS engines is built to endure exposure to moisture and saltwater, ensuring long-term durability and performance 12.

Grouping Considerations

When considering the compatibility of the ECM Wiring Harness with the QSK60 and CM850 engines, it is important to note that these engines share similar design philosophies and electrical requirements. The harness is designed to fit both engines seamlessly, providing a standardized solution for these high-performance models.

For the MCRS engines, while the wiring harness is also compatible, it is tailored to meet the specific needs of marine applications. This includes enhanced protection against corrosion and environmental factors that are common in marine settings 13.

Understanding the Integration of Part 2871206 Electronic Control Module Wiring Harness in Engine Systems

The part 2871206 ECM Wiring Harness is an essential component that facilitates the communication and power distribution between the ECM and various engine system components. This harness is meticulously designed to ensure reliable and efficient operation of the engine by connecting the ECM to sensors, actuators, and other control units.

Role in Engine Systems

-

Sensor Connectivity: The harness connects the ECM to a variety of sensors such as the Mass Air Flow (MAF) sensor, Manifold Absolute Pressure (MAP) sensor, and Oxygen (O2) sensors. These sensors provide real-time data to the ECM, allowing it to make precise adjustments to fuel delivery, ignition timing, and other critical parameters 14.

-

Actuator Control: It also interfaces with actuators like the fuel injectors, throttle body, and variable valve timing (VVT) solenoids. The ECM sends signals through the harness to these actuators, enabling them to perform their functions accurately and in sync with engine requirements 15.

-

Power Distribution: The harness is responsible for distributing power from the battery to the ECM and other electronic components. This ensures that all systems receive the necessary voltage to operate correctly 16.

-

Grounding: Proper grounding is vital for the ECM to function correctly. The harness includes ground wires that connect the ECM and other components to the vehicle’s chassis, ensuring a stable electrical environment 17.

-

Communication Networks: In modern engine systems, the ECM Wiring Harness often integrates with Controller Area Network (CAN) buses. This allows for seamless communication between the ECM and other control modules, such as the Transmission Control Module (TCM) and Anti-lock Braking System (ABS) module 18.

-

Diagnostic Capabilities: The harness facilitates On-Board Diagnostics (OBD) by providing the necessary connections for diagnostic tools to interface with the ECM. This allows mechanics to retrieve error codes and monitor system performance in real-time 19.

-

Thermal Management: Some harnesses include temperature sensors that monitor the ECM’s operating temperature. This data helps the ECM make adjustments to prevent overheating and ensure optimal performance 20.

Conclusion

By understanding the comprehensive role of the part 2871206 ECM Wiring Harness, engineers and mechanics can better appreciate its significance in maintaining the overall health and efficiency of engine systems. Proper installation, maintenance, and troubleshooting of this Cummins part are essential for ensuring the reliable operation of commercial trucks and Cummins engines.

-

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Steve Rendle, Martynn Randall. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Owners Manual, Bulletin Number 4383642.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Steve Rendle, Martynn Randall. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Owners Manual, Bulletin Number 4383642.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Cummins Inc. (n.d.). Company Overview. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). QSK60 and CM850 Engine Specifications. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). MCRS Engine Specifications. Retrieved from Cummins official website.

↩ -

Cummins Inc. (n.d.). ECM Wiring Harness Compatibility Guide. Retrieved from Cummins official website.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Steve Rendle, Martynn Randall. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩ -

Cummins Inc. (n.d.). Owners Manual, Bulletin Number 4383642.

↩ -

Robert Bosch GmbH. (2014). Bosch Automotive Handbook 9th Edition. Robert Bosch GmbH.

↩ -

Andrew Norman. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ -

Steve Rendle, Martynn Randall. (2000). Haynes Diesel Engine Systems and Data Book. Haynes Publishing.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.