This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 2871207 Starting Motor is a component designed for use in commercial trucks. It plays a role in the engine’s ignition process, ensuring that the truck can start reliably under various conditions. This motor is integral to the operation of trucks, facilitating the initial cranking of the engine which is necessary for combustion to begin.

Basic Concepts of Starting Motors

A starting motor, also known as a starter, is an electric motor that converts electrical energy into mechanical energy. This conversion allows the motor to rotate the engine’s crankshaft, initiating the start-up sequence. In the ignition system of a truck, the starting motor is activated when the driver turns the ignition key or presses the start button, sending a current from the battery to the motor 1.

Purpose of the Cummins 2871207 Starting Motor

This Cummins part is specifically engineered to provide the necessary torque to turn over the engine of a commercial truck. It plays a role in the engine’s start-up process by engaging with the flywheel or flexplate, which in turn rotates the crankshaft. This action compresses the air-fuel mixture in the cylinders, allowing the engine to start 2.

Key Features

The Cummins 2871207 Starting Motor is characterized by its robust design and construction. It is built using high-quality materials to ensure durability and reliability. The motor incorporates advanced technological features such as improved electrical contacts and a more efficient gear reduction system, which contribute to its performance and longevity 3.

Benefits

This part offers several advantages. Its reliable operation ensures consistent engine start-ups, even in challenging conditions. The motor’s efficient design contributes to reduced electrical draw, preserving battery life. Additionally, its performance enhancements can lead to smoother and quicker engine starts, improving overall truck operation 4.

Installation and Integration

Proper installation of the Cummins 2871207 Starting Motor is crucial for its effective operation. It should be securely mounted to the engine and correctly aligned with the flywheel or flexplate. Electrical connections must be tight and free from corrosion to ensure a strong and consistent current flow. Following the manufacturer’s guidelines during installation will help integrate the motor seamlessly into the truck’s engine system.

Maintenance and Care

To ensure the longevity and optimal performance of the Cummins 2871207 Starting Motor, routine maintenance is recommended. This includes checking and tightening electrical connections, inspecting the motor for signs of wear or damage, and ensuring that the battery is in good condition. Regular maintenance helps prevent unexpected failures and extends the service life of the starting motor.

Troubleshooting Common Issues

Common problems with starting motors can include slow cranking, clicking sounds when attempting to start the engine, or the motor not engaging at all. Troubleshooting these issues may involve checking the battery’s charge, inspecting the starter solenoid, and ensuring that the motor’s electrical connections are secure and free from corrosion. For the Cummins 2871207 model, specific diagnostic procedures can be followed to identify and resolve these problems.

Performance Enhancements

While the Cummins 2871207 Starting Motor is designed for optimal performance, there are potential upgrades or modifications that can further improve its efficiency. These may include upgrading to higher-capacity batteries, ensuring the electrical system is optimized for the motor’s requirements, or installing a performance-enhancing gear reduction system. Such enhancements can lead to quicker and more reliable engine starts.

Safety Considerations

When working with the Cummins 2871207 Starting Motor, it is important to observe safety guidelines to prevent accidents. This includes disconnecting the battery before beginning any work on the motor, using appropriate personal protective equipment, and ensuring that all tools and equipment are in good condition. Adhering to these safety practices helps ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive and commercial truck industry. The company’s commitment to excellence is reflected in its wide range of products, including the Cummins 2871207 Starting Motor, which is designed to meet the demanding requirements of commercial truck applications.

Cummins Starting Motor 2871207 Compatibility

The Cummins part number 2871207, which is a Starting Motor, is designed to be compatible with a range of Cummins engines. This part is engineered to ensure reliable and efficient engine starting across various engine models. Here is a detailed look at the compatibility of this starting motor with specific Cummins engines:

QSK60 Series

The QSK60 series engines are known for their robust performance and reliability in heavy-duty applications. The Cummins Starting Motor 2871207 is specifically designed to fit seamlessly with the QSK60 engines, ensuring that the starting process is smooth and efficient. This compatibility is crucial for maintaining the operational integrity of these engines in demanding environments.

CM850 Series

The CM850 series engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are widely used in various applications, including commercial vehicles and industrial machinery. The Starting Motor 2871207 is engineered to provide reliable starting performance for the CM850 engines, ensuring that these engines can be started quickly and efficiently, even under challenging conditions.

MCRS Series

The MCRS series engines are designed for marine applications, providing powerful and reliable performance in marine environments. The Cummins Starting Motor 2871207 is compatible with the MCRS series, ensuring that these engines can be started reliably in marine settings. This compatibility is essential for maintaining the operational efficiency of marine vessels and equipment.

Grouping Compatibility

The Cummins Starting Motor 2871207 is designed to provide a broad range of compatibility across different engine series. This ensures that the part can be used in various applications, from heavy-duty industrial engines to medium-duty commercial vehicles and marine engines. The design and engineering of this starting motor focus on delivering consistent performance and reliability across these diverse engine types.

By ensuring compatibility with the QSK60, CM850, and MCRS series engines, the Cummins Starting Motor 2871207 offers a versatile solution for maintaining the operational efficiency of these engines in their respective applications.

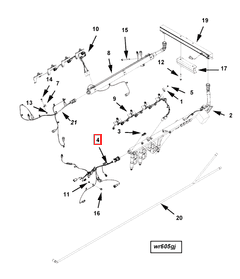

Role of Part 2871207 Starting Motor in the Provided Components

The Part 2871207 Starting Motor is integral to the operation of several key components within the engine system. Its primary function is to initiate the engine’s operation by converting electrical energy into mechanical energy, which cranks the engine.

Interaction with the Harness

The harness is a network of wires that transmit electrical power and signals throughout the vehicle. The Starting Motor relies on the harness to receive the necessary electrical current from the battery. This current is essential for the motor to function, as it powers the solenoid and the motor itself. The harness ensures a consistent and reliable flow of electricity, which is vital for the Starting Motor to perform its role effectively.

Integration with the Electronic Control Module (ECM) Wiring

The Electronic Control Module (ECM) is the brain of the engine system, managing various functions to optimize performance and efficiency. The ECM wiring connects the ECM to other components, including the Starting Motor. When the ignition is turned on, the ECM sends a signal through its wiring to the Starting Motor, instructing it to engage. This signal is part of a sequence that ensures the engine starts smoothly and efficiently. The ECM wiring also facilitates feedback from the Starting Motor, allowing the ECM to monitor the motor’s performance and make adjustments as needed.

In summary, the Part 2871207 Starting Motor works in concert with the harness and ECM wiring to ensure the engine starts reliably and operates efficiently. The harness provides the necessary electrical power, while the ECM wiring facilitates communication and control, making the Starting Motor a key component in the engine system.

Conclusion

The Cummins 2871207 Starting Motor is a critical component in the reliable start-up of commercial truck engines. Its robust design, advanced features, and compatibility with various Cummins engine series make it a versatile and dependable choice for heavy-duty applications. Proper installation, maintenance, and adherence to safety guidelines are essential for ensuring the optimal performance and longevity of this part.

-

Proceedings of the 5th Commercial Vehicle Technology Symposium CVT, Karsten Berns, Klaus Dressler, Patrick Fleischmann, Daniel Grges, Ralf Kalmar, Bernd Sauer, Nicole Stephan, Roman Teutsch, Martin Thul, Springer, 2018.

↩ -

Diesel Engine Management Systems and Components, Konrad Reif Ed, Springer Vieweg, 2014.

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998.

↩ -

Bosch Fuel Injection Systems, Forbes Aird, HP Books, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.