This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

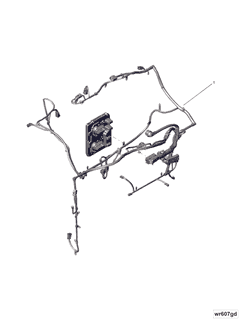

The 2873840 Electronic Control Module Wiring Harness is a component designed by Cummins to facilitate the electrical connections necessary for the operation of commercial trucks. This wiring harness is integral to the truck’s electrical system, ensuring that the Electronic Control Module (ECM) and other electronic components communicate effectively. Cummins, a renowned manufacturer in the automotive and heavy-duty truck industry, is known for its commitment to quality and innovation in producing such components.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness consists of a network of wires, connectors, and terminals that link various electronic components within a truck’s electrical system. Its primary function is to transmit electrical signals and power between the ECM and other systems, ensuring seamless operation. The harness is designed to withstand the harsh conditions typically encountered in commercial trucking, including vibrations, temperature fluctuations, and exposure to chemicals 1.

Role of the 2873840 Wiring Harness in Truck Operation

The 2873840 Wiring Harness plays a specific role in the operation of a commercial truck by providing the necessary electrical connections for the ECM to interact with other systems. This interaction allows the ECM to monitor and control various functions such as engine performance, transmission shifting, and braking systems. The harness ensures that these systems receive the correct signals and power, contributing to the overall efficiency and reliability of the truck 2.

Key Features of the 2873840 Wiring Harness

The 2873840 Wiring Harness is characterized by its robust design and the use of high-quality materials. It features a durable construction that resists wear and tear, ensuring long-term reliability. The harness is also designed with precision to fit snugly within the truck’s electrical system, minimizing the risk of loose connections. Additionally, it incorporates advanced technology to enhance signal transmission and reduce the likelihood of electrical interference.

Benefits of Using the 2873840 Wiring Harness

Utilizing the 2873840 Wiring Harness offers several benefits, including improved reliability and efficiency in the truck’s electrical system. Its design facilitates easier installation and maintenance, reducing downtime and operational costs. The harness’s durability ensures that it can withstand the demanding conditions of commercial trucking, contributing to the overall longevity of the truck’s electrical components.

Troubleshooting Common Issues with the 2873840 Wiring Harness

Identifying and troubleshooting common issues with the 2873840 Wiring Harness involves a systematic approach. Diagnostic procedures may include visual inspections for signs of wear or damage, testing electrical connections for continuity, and using diagnostic tools to identify faulty signals. Potential solutions range from repairing or replacing damaged sections of the harness to reconfiguring connections to ensure optimal signal transmission.

Maintenance Tips for the 2873840 Wiring Harness

Maintaining the 2873840 Wiring Harness is crucial for ensuring its optimal performance and longevity. Regular inspection routines should be established to check for signs of wear, corrosion, or loose connections. Care practices may include cleaning the harness to remove dirt and debris that could interfere with electrical connections, and applying protective coatings to enhance its resistance to environmental factors.

Integration with Other Truck Systems

The 2873840 Wiring Harness integrates with various systems within the truck, including the engine, transmission, and braking systems. This integration is vital for the overall performance of the truck, as it allows for coordinated operation among these systems. The harness facilitates the exchange of data and power, enabling the ECM to make real-time adjustments to enhance efficiency and safety.

Safety Considerations

When installing, maintaining, or troubleshooting the 2873840 Wiring Harness, it is important to observe safety considerations. Proper handling procedures should be followed to avoid electrical shocks or damage to the harness. Safety equipment, such as insulated tools and protective gear, should be used to ensure the safety of personnel working with the electrical system.

Environmental Impact and Sustainability

The environmental impact of the 2873840 Wiring Harness and Cummins’ efforts towards sustainability in manufacturing and design are noteworthy. Cummins is committed to reducing the environmental footprint of its products through the use of recyclable materials and energy-efficient manufacturing processes. The design of the harness also considers longevity and reusability, contributing to sustainability efforts.

About Cummins

Cummins is a leading manufacturer in the automotive and heavy-duty truck industry, with a reputation for quality and innovation. The company’s history is marked by a commitment to developing reliable and efficient components that meet the demanding needs of commercial trucking. Cummins’ dedication to excellence is evident in its products, including the 2873840 Electronic Control Module Wiring Harness.

Conclusion

The 2873840 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks, ensuring the seamless communication between the ECM and other electronic systems. Its robust design, integration capabilities, and the benefits it offers in terms of reliability and efficiency make it an indispensable part of modern truck electrical systems. Regular maintenance and adherence to safety protocols are essential for maximizing the performance and longevity of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.