This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

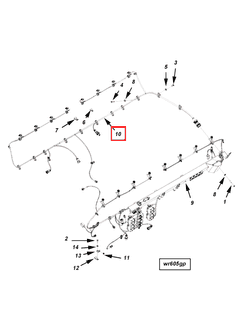

The 2891146 Electronic Control Module Wiring Harness is a vital component in the operation of commercial trucks, manufactured by Cummins. This wiring harness is designed to facilitate the communication between the Electronic Control Module (ECM) and various sensors and actuators within the truck’s electrical system. Cummins, a well-established manufacturer in the automotive industry, is known for its commitment to quality and innovation, making the 2891146 Wiring Harness a reliable choice for truck operators 1.

Basic Concepts of Electronic Control Module Wiring Harness

An Electronic Control Module Wiring Harness is a network of wires and connectors that link the ECM to different sensors and actuators throughout the truck. This harness plays a role in transmitting signals and data between the ECM and these components, enabling the ECM to monitor and control various functions of the truck. The components of the wiring harness include wires, connectors, and protective coverings, all of which are designed to withstand the harsh conditions often encountered in commercial trucking 2.

Purpose of the 2891146 Electronic Control Module Wiring Harness

The 2891146 Wiring Harness is specifically designed to enhance the operation of commercial trucks by ensuring seamless communication between the ECM and other electronic components. This communication is vital for the proper functioning of the truck’s engine and other systems. The harness allows the ECM to receive data from sensors and send commands to actuators, thereby optimizing the performance and efficiency of the truck 3.

Key Features

The 2891146 Wiring Harness boasts several key features that contribute to its performance and durability. Its design incorporates high-quality materials that are resistant to wear and environmental factors. The harness is engineered to provide reliable connections and efficient signal transmission. Additionally, it features protective coverings that shield the wires from physical damage and corrosion, ensuring long-lasting operation.

Benefits

The 2891146 Wiring Harness offers several benefits that contribute to the overall efficiency and safety of the truck. Improved reliability is one of the primary advantages, as the harness ensures consistent communication between the ECM and other components. Enhanced performance is another benefit, as the harness allows for precise control and monitoring of the truck’s systems. Easier maintenance is also a notable benefit, as the harness is designed for straightforward installation and troubleshooting.

Installation Considerations

Proper installation of the 2891146 Wiring Harness is crucial for its effective operation. It is important to follow the manufacturer’s recommendations regarding placement and connections. Ensuring that the harness is correctly installed will help prevent issues and ensure optimal performance. Attention to detail during installation can also contribute to the longevity of the harness.

Troubleshooting Common Issues

Common issues that may arise with the 2891146 Wiring Harness include signal interference, connection problems, and physical damage to the wires. Troubleshooting these issues involves inspecting the harness for signs of wear or damage, checking connections for security, and ensuring that the harness is properly routed to avoid interference. Regular inspections and maintenance can help prevent these issues from occurring.

Maintenance Tips

Maintaining the 2891146 Wiring Harness is important for ensuring its longevity and optimal performance. Keeping the harness clean and free from debris can help prevent corrosion and damage. Regularly checking for signs of wear and tear, such as frayed wires or loose connections, is also important. Addressing any issues promptly can help maintain the efficiency and safety of the truck.

Cummins: Manufacturer Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company is known for its commitment to innovation and quality, which is reflected in its products, including the 2891146 Wiring Harness. Cummins’ reputation for reliability and performance makes it a trusted choice for truck operators and manufacturers alike.

Role of Part 2891146 Electronic Control Module Wiring Harness in Engine Systems

The Electronic Control Module (ECM) Wiring Harness, specifically part 2891146, is integral to the operation of modern engine systems. This harness serves as the vital link between the ECM and various engine components, facilitating the transmission of electrical signals that are essential for engine management and performance.

Integration with Engine Components

-

Sensors: The ECM Wiring Harness connects various sensors such as the Mass Air Flow (MAF) sensor, Oxygen (O2) sensors, and Manifold Absolute Pressure (MAP) sensor to the ECM. These sensors provide real-time data on air intake, oxygen levels, and pressure within the intake manifold, allowing the ECM to make precise adjustments to fuel delivery and ignition timing.

-

Actuators: This harness also interfaces with actuators including the fuel injectors, throttle body, and various solenoids. By transmitting commands from the ECM, it ensures that these components operate in harmony with the engine’s requirements, optimizing performance and efficiency.

-

Ignition System: The harness plays a key role in connecting the ECM to the ignition coils and spark plugs. It ensures that the ignition timing is accurately controlled, which is vital for combustion efficiency and overall engine performance.

-

Emission Control Systems: Components such as the Exhaust Gas Recirculation (EGR) valve and the Evaporative Emission Control (EVAP) system rely on the ECM Wiring Harness for proper function. It allows the ECM to monitor and control these systems to meet emission standards and enhance engine efficiency.

-

Battery and Alternator: The harness also facilitates communication between the ECM and the vehicle’s electrical system, including the battery and alternator. This ensures that the ECM receives consistent power and can accurately monitor the electrical load on the system.

Enhanced Engine Management

By providing a robust and reliable connection between the ECM and these critical components, the ECM Wiring Harness part 2891146 enables sophisticated engine management. This results in improved fuel economy, reduced emissions, and enhanced overall performance. The harness’s design ensures that it can withstand the harsh environment under the hood, maintaining signal integrity and component functionality over the vehicle’s lifespan.

Conclusion

The 2891146 Electronic Control Module Wiring Harness is a critical component in the operation of commercial trucks, ensuring seamless communication between the ECM and various sensors and actuators. Its high-quality design, durability, and reliable performance make it an essential part of modern engine systems. Proper installation, maintenance, and troubleshooting are key to maximizing the benefits of this Cummins part, contributing to the overall efficiency and safety of the truck.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.